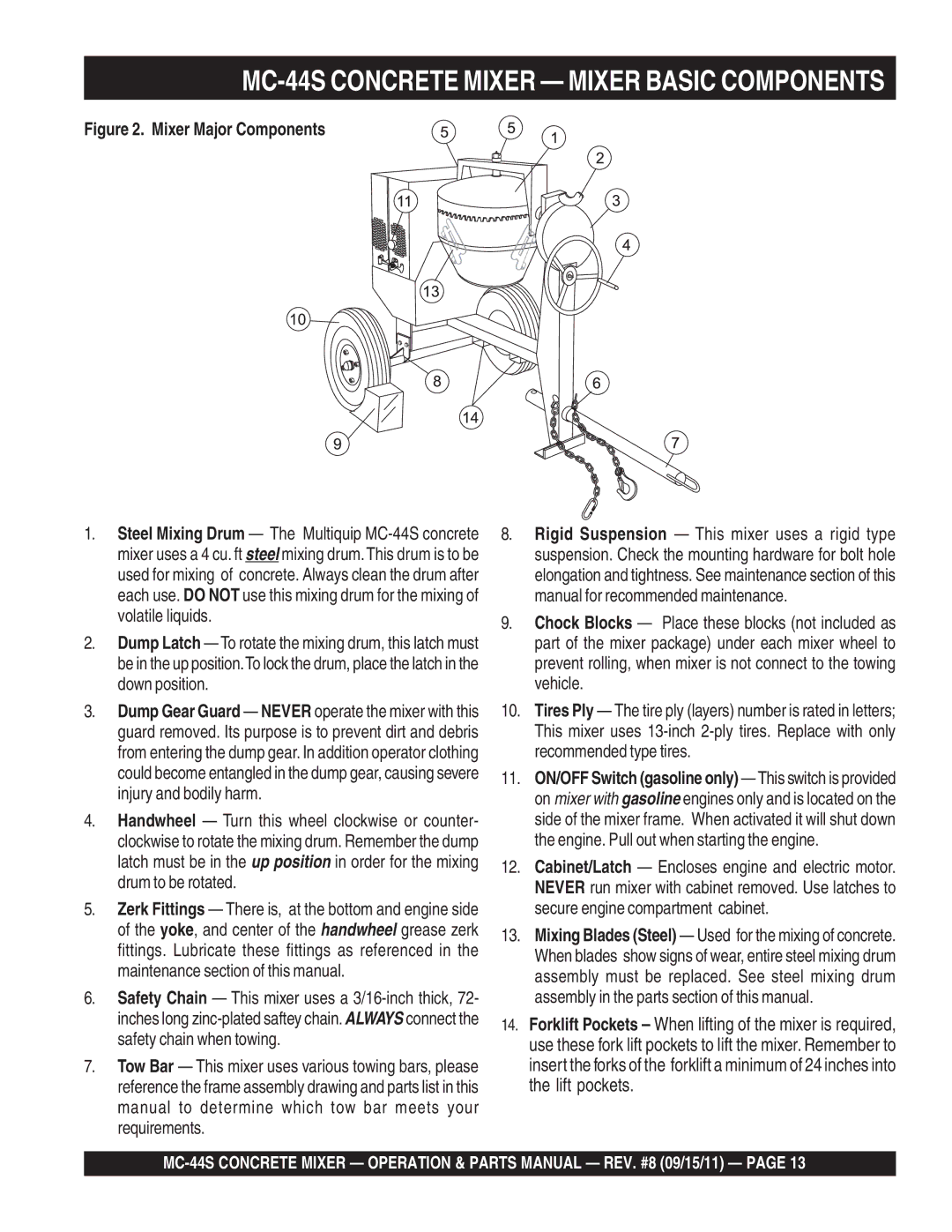

MC-44S CONCRETE MIXER — MIXER BASIC COMPONENTS

Figure 2. Mixer Major Components

1.Steel Mixing Drum — The Multiquip

2.Dump Latch — To rotate the mixing drum, this latch must be in the up position.To lock the drum, place the latch in the down position.

3.Dump Gear Guard — NEVER operate the mixer with this guard removed. Its purpose is to prevent dirt and debris from entering the dump gear. In addition operator clothing could become entangled in the dump gear, causing severe injury and bodily harm.

4.Handwheel — Turn this wheel clockwise or counter- clockwise to rotate the mixing drum. Remember the dump latch must be in the up position in order for the mixing drum to be rotated.

5.Zerk Fittings — There is, at the bottom and engine side of the yoke, and center of the handwheel grease zerk fittings. Lubricate these fittings as referenced in the maintenance section of this manual.

6.Safety Chain — This mixer uses a

7.Tow Bar — This mixer uses various towing bars, please reference the frame assembly drawing and parts list in this manual to determine which tow bar meets your requirements.

8.Rigid Suspension — This mixer uses a rigid type suspension. Check the mounting hardware for bolt hole elongation and tightness. See maintenance section of this manual for recommended maintenance.

9.Chock Blocks — Place these blocks (not included as part of the mixer package) under each mixer wheel to prevent rolling, when mixer is not connect to the towing vehicle.

10.Tires Ply — The tire ply (layers) number is rated in letters; This mixer uses

11.ON/OFF Switch (gasoline only) — This switch is provided on mixer with gasoline engines only and is located on the side of the mixer frame. When activated it will shut down the engine. Pull out when starting the engine.

12.Cabinet/Latch — Encloses engine and electric motor. NEVER run mixer with cabinet removed. Use latches to secure engine compartment cabinet.

13.Mixing Blades (Steel) — Used for the mixing of concrete. When blades show signs of wear, entire steel mixing drum assembly must be replaced. See steel mixing drum assembly in the parts section of this manual.

14.Forklift Pockets – When lifting of the mixer is required, use these fork lift pockets to lift the mixer. Remember to insert the forks of the forklift a minimum of 24 inches into the lift pockets.