This section is intended to assist the operator with the initial

DO NOT use your rammer until this section is thoroughly understood.

CAUTION:

Failure to understand the operation of the MT- 85H Tamping Rammer could result in severe damage to the trowel or personal injury.

Rammer Gearbox and Spring Cylinder Oil Bath

This unit uses an oil bath lubrication system. Perform the following:

1.Check the oil level through the oil level sight glass at the rear of the tamper foot.

2.If oil is not visible, add

NOTE

The oil level should be kept at the half way point of the sight glass.

Engine

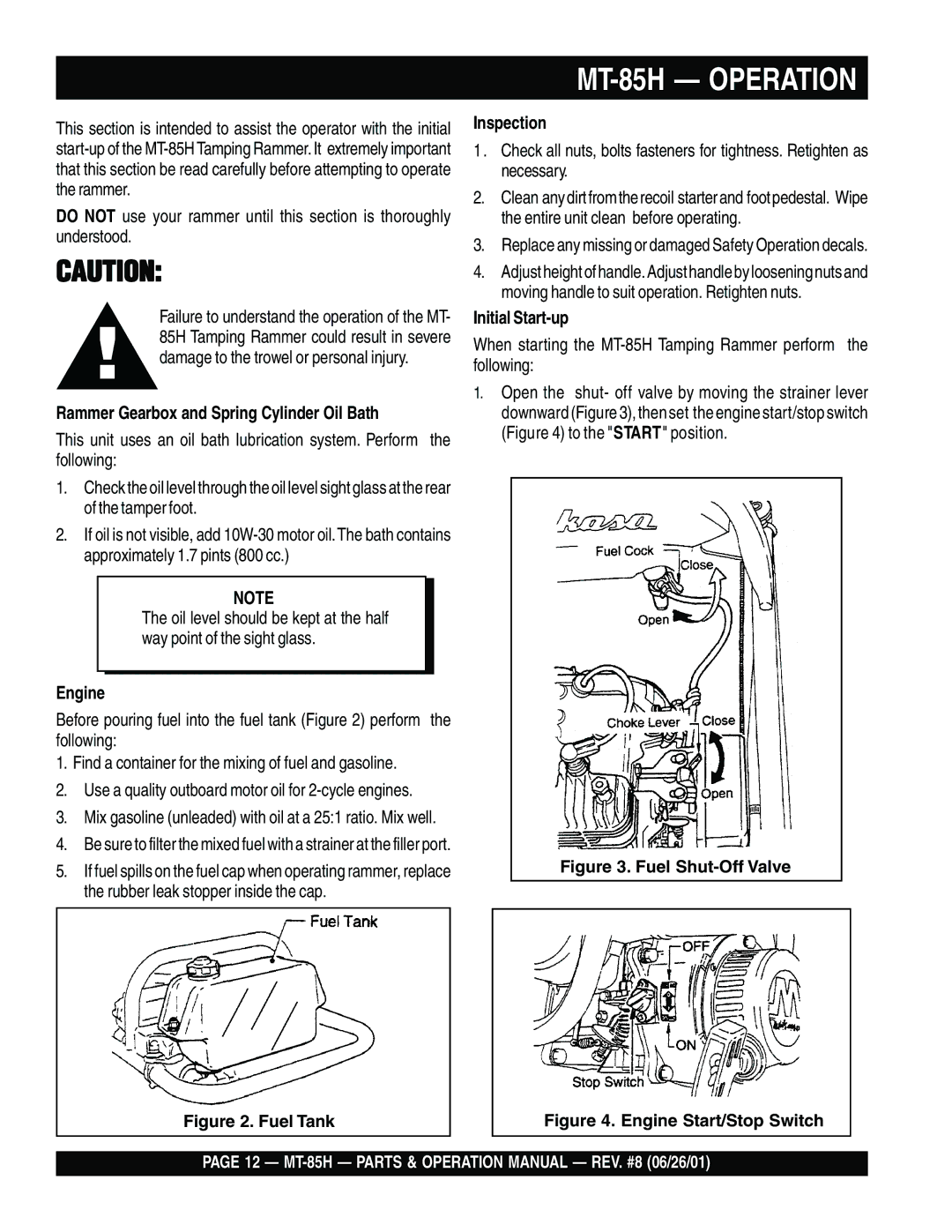

Before pouring fuel into the fuel tank (Figure 2) perform the following:

1.Find a container for the mixing of fuel and gasoline.

2.Use a quality outboard motor oil for 2-cycle engines.

3.Mix gasoline (unleaded) with oil at a 25:1 ratio. Mix well.

4.Be sure to filter the mixed fuel with a strainer at the filler port.

5.If fuel spills on the fuel cap when operating rammer, replace the rubber leak stopper inside the cap.

MT-85H — OPERATION

Inspection

1 . Check all nuts, bolts fasteners for tightness. Retighten as necessary.

2.Clean any dirt from the recoil starter and foot pedestal. Wipe the entire unit clean before operating.

3.Replace any missing or damaged Safety Operation decals.

4.Adjust height of handle. Adjust handle by loosening nuts and moving handle to suit operation. Retighten nuts.

Initial Start-up

When starting the

1.Open the shut- off valve by moving the strainer lever downward (Figure 3), then set the engine start/stop switch (Figure 4) to the "START" position.

Figure 3. Fuel Shut-Off Valve

Figure 2. Fuel Tank

Figure 4. Engine Start/Stop Switch

PAGE 12 —