MT-86D2TAMPING RAMMER — MAINTENANCE

MAINTENANCE

Perform the scheduled maintenance procedures as indicated:

Daily

■Thoroughly remove dirt and oil from the engine and control area.

■Clean or replaces air cleaner as necessary.

■Check and retighten all fasteners as necessary.

■Check spring box and bellows for oil leaks. Repair as needed.

■Remove element from

Weekly (every 50 hours)

■Remove the fuel filter cap and inspect for dirt in the fuel tank. See Figure 9.

Figure 9. Removing Fuel Filter Cap

Replacement of Lubricant (Body)

■Remove the drain plug at the rear of tamper foot and drain the dirty oil. Refill with clean oil to the middle of the sight glass. Oil bath contains approx. 1.7 pt. (800 cc).

INITIAL OIL CHANGE:

After 50 hours of operation.

SECOND OIL CHANGE AND/OR LATER

Every 200 hours of operation.

Replacement of Lubricant (ENGINE)

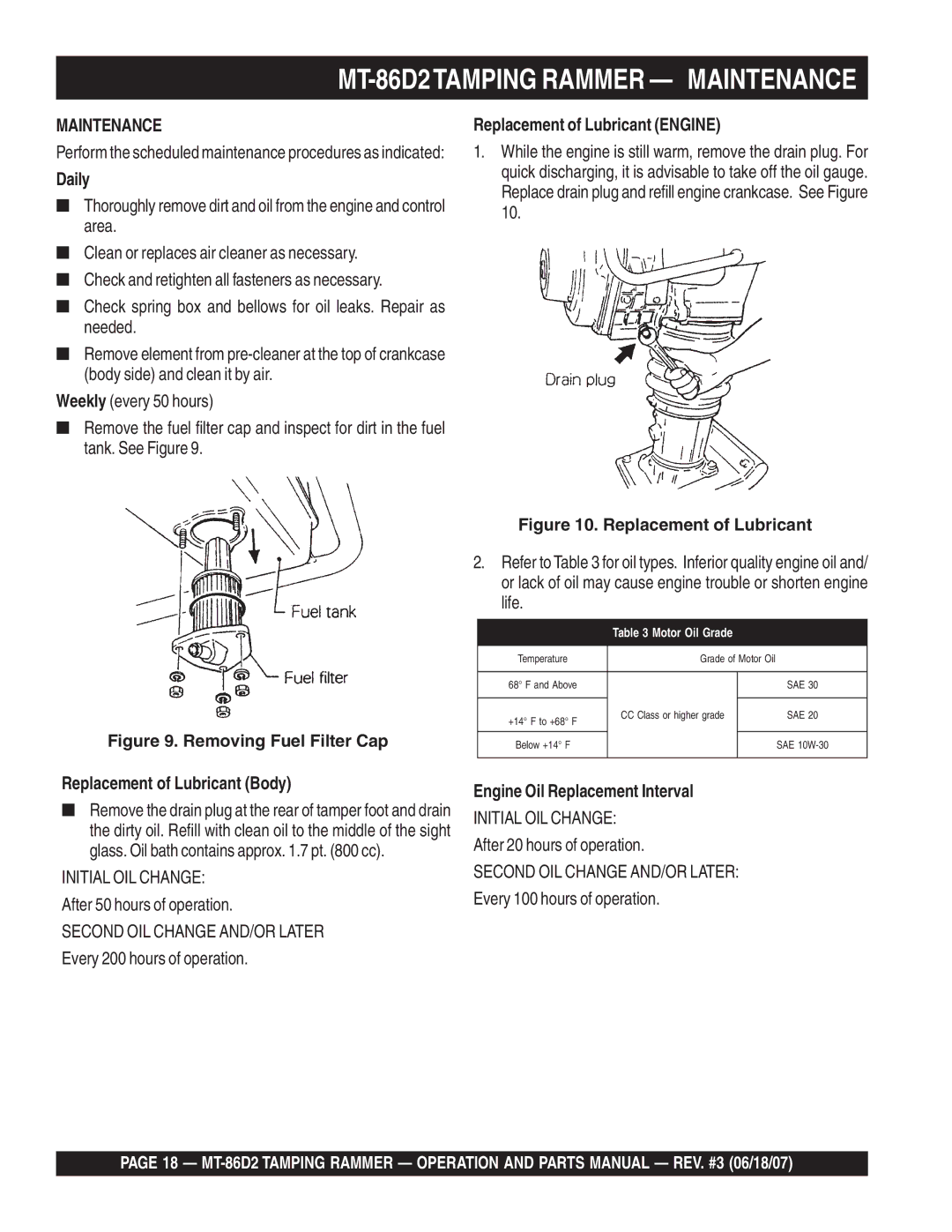

1.While the engine is still warm, remove the drain plug. For quick discharging, it is advisable to take off the oil gauge. Replace drain plug and refill engine crankcase. See Figure 10.

Figure 10. Replacement of Lubricant

2.Refer to Table 3 for oil types. Inferior quality engine oil and/ or lack of oil may cause engine trouble or shorten engine life.

Table 3 Motor Oil Grade

Temperature | Grade of Motor Oil |

| |

|

|

|

|

68° F and Above |

|

| SAE 30 |

|

|

|

|

+14° F to +68° F | CC Class or higher grade |

| SAE 20 |

|

|

| |

|

|

|

|

Below +14° F |

|

| SAE |

|

|

|

|

Engine Oil Replacement Interval

INITIAL OIL CHANGE:

After 20 hours of operation.

SECOND OIL CHANGE AND/OR LATER:

Every 100 hours of operation.

PAGE 18 —