MVH-150D2 — OPERATION/PREPARATION FOR LONGTERM STORAGE

CAUTION - Safety Rules

Make sure to follow all safety rules referenced in the safety sectionofthismanualbeforeoperatingcompactor. Keepwork area clear of debris and other objects that could cause damage to the compactor or bodily injury.

3.To make the compactor move in the forward direction push the travel lever ( Figure 16) forward.To make the compactor moveinthereversedirection pullthetravellever backwards.

Normal Shut-Down Procedure:

1.Place the speed control lever in the IDLE position. Allow the engine to cool down for 2 to 3 minutes.

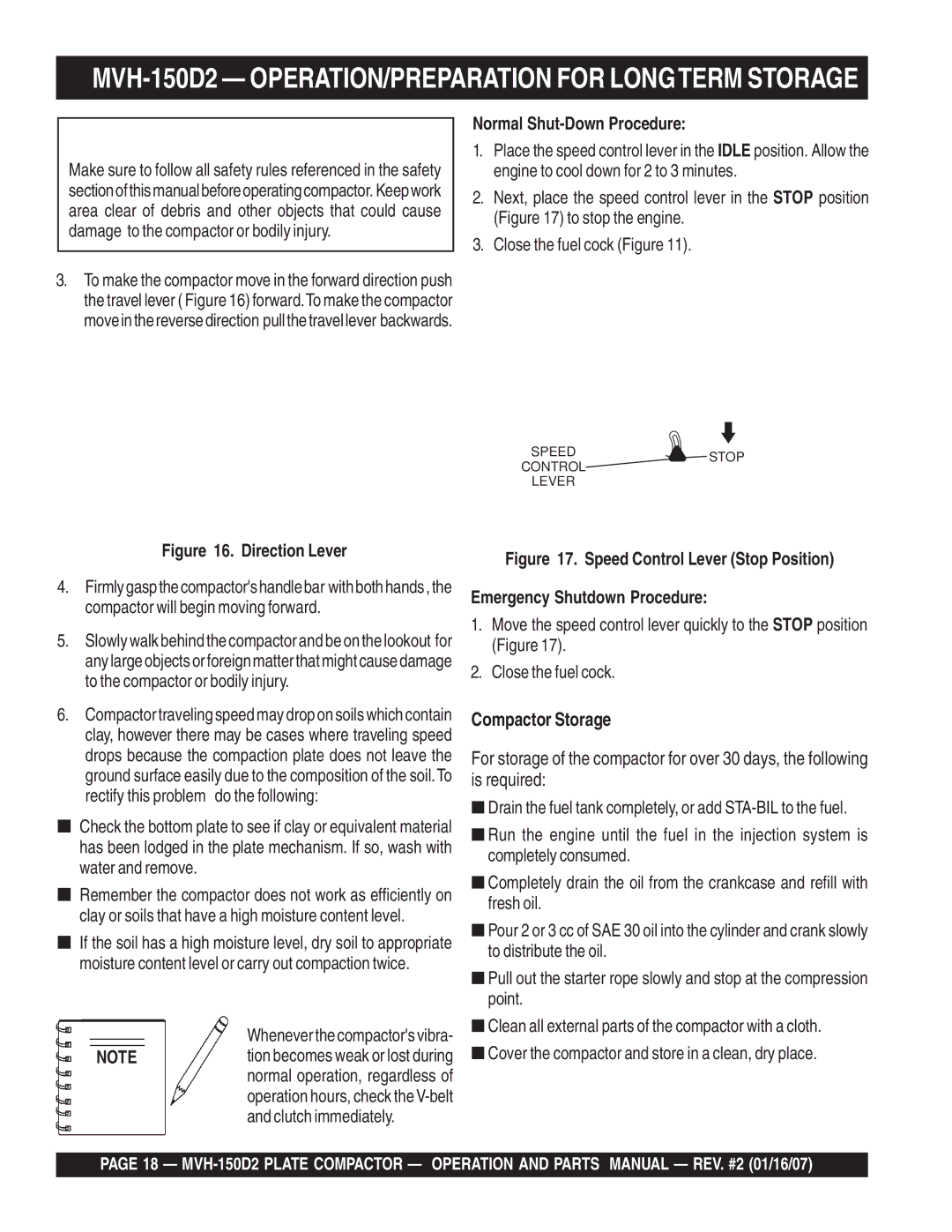

2.Next, place the speed control lever in the STOP position (Figure 17) to stop the engine.

3.Close the fuel cock (Figure 11).

SPEED![]() STOP

STOP

CONTROL

LEVER

Figure 16. Direction Lever

4.Firmlygaspthecompactor'shandlebar withbothhands,the compactor will begin moving forward.

5.Slowly walk behind the compactor and be on the lookout for anylargeobjectsorforeignmatterthatmightcausedamage to the compactor or bodily injury.

6.Compactortravelingspeedmaydroponsoilswhichcontain clay, however there may be cases where traveling speed drops because the compaction plate does not leave the ground surface easily due to the composition of the soil.To rectify this problem do the following:

■Check the bottom plate to see if clay or equivalent material has been lodged in the plate mechanism. If so, wash with water and remove.

■Remember the compactor does not work as efficiently on clay or soils that have a high moisture content level.

■If the soil has a high moisture level, dry soil to appropriate moisture content level or carry out compaction twice.

Wheneverthecompactor'svibra-

NOTEtion becomes weak or lost during normal operation, regardless of operation hours, check

Figure 17. Speed Control Lever (Stop Position) Emergency Shutdown Procedure:

1.Move the speed control lever quickly to the STOP position (Figure 17).

2.Close the fuel cock.

Compactor Storage

For storage of the compactor for over 30 days, the following is required:

■Drain the fuel tank completely, or add

■Run the engine until the fuel in the injection system is completely consumed.

■Completely drain the oil from the crankcase and refill with fresh oil.

■Pour 2 or 3 cc of SAE 30 oil into the cylinder and crank slowly to distribute the oil.

■Pull out the starter rope slowly and stop at the compression point.

■Clean all external parts of the compactor with a cloth.

■Cover the compactor and store in a clean, dry place.

PAGE 18 —