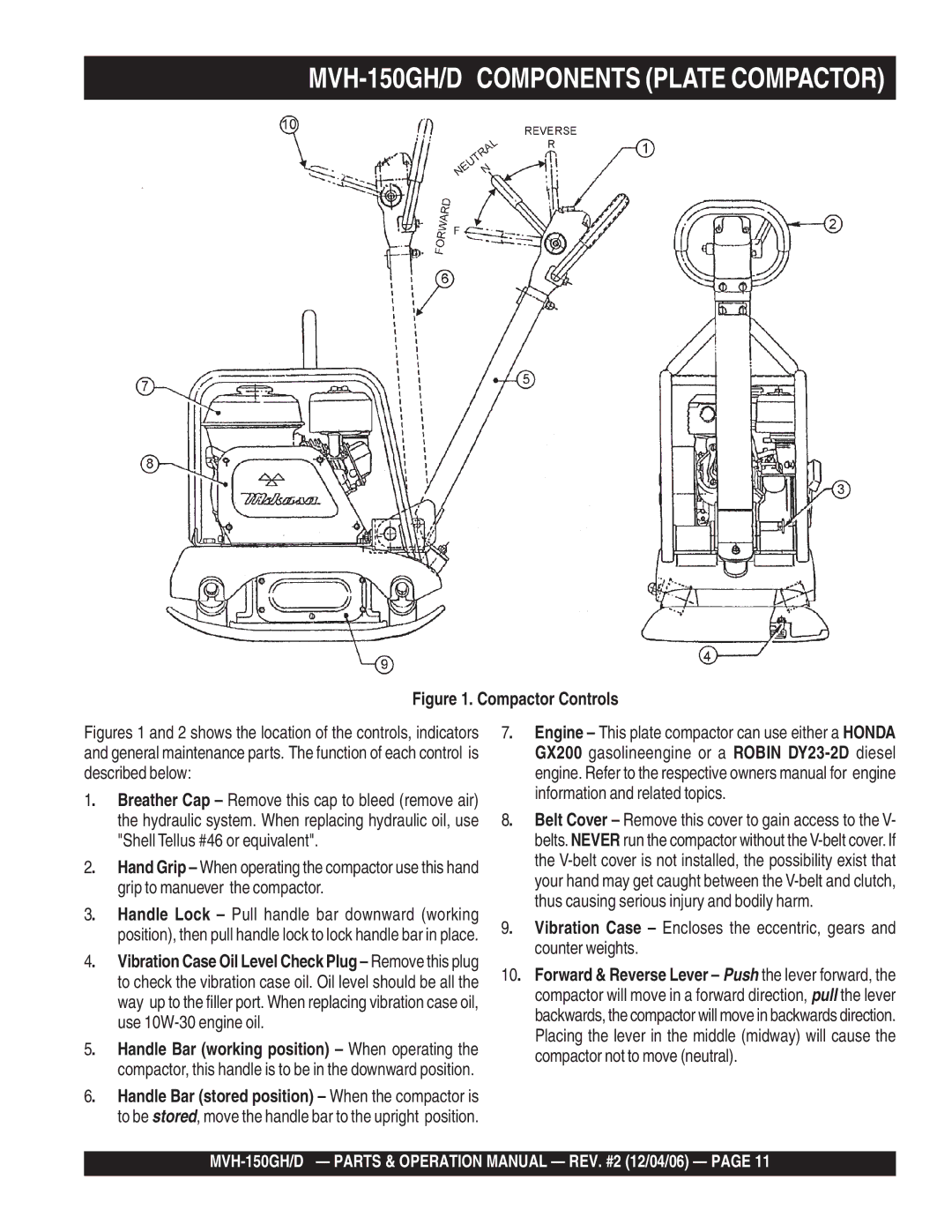

MVH-150GH/D COMPONENTS (PLATE COMPACTOR)

Figure 1. Compactor Controls

Figures 1 and 2 shows the location of the controls, indicators and general maintenance parts. The function of each control is described below:

1. Breather Cap – Remove this cap to bleed (remove air) the hydraulic system. When replacing hydraulic oil, use "Shell Tellus #46 or equivalent".

2. Hand Grip – When operating the compactor use this hand grip to manuever the compactor.

3. Handle Lock – Pull handle bar downward (working position), then pull handle lock to lock handle bar in place.

4. Vibration Case Oil Level Check Plug – Remove this plug to check the vibration case oil. Oil level should be all the way up to the filler port. When replacing vibration case oil, use

5. Handle Bar (working position) – When operating the compactor, this handle is to be in the downward position.

6. Handle Bar (stored position) – When the compactor is to be stored, move the handle bar to the upright position.

7. | Engine – This plate compactor can use either a HONDA |

| GX200 gasolineengine or a ROBIN |

| engine. Refer to the respective owners manual for engine |

| information and related topics. |

8. | Belt Cover – Remove this cover to gain access to the V- |

| belts.NEVER run the compactor without the |

| the |

| your hand may get caught between the |

| thus causing serious injury and bodily harm. |

9. Vibration Case – Encloses the eccentric, gears and counter weights.

10. Forward & Reverse Lever – Push the lever forward, the compactor will move in a forward direction, pull the lever backwards, the compactor will move in backwards direction. Placing the lever in the middle (midway) will cause the compactor not to move (neutral).