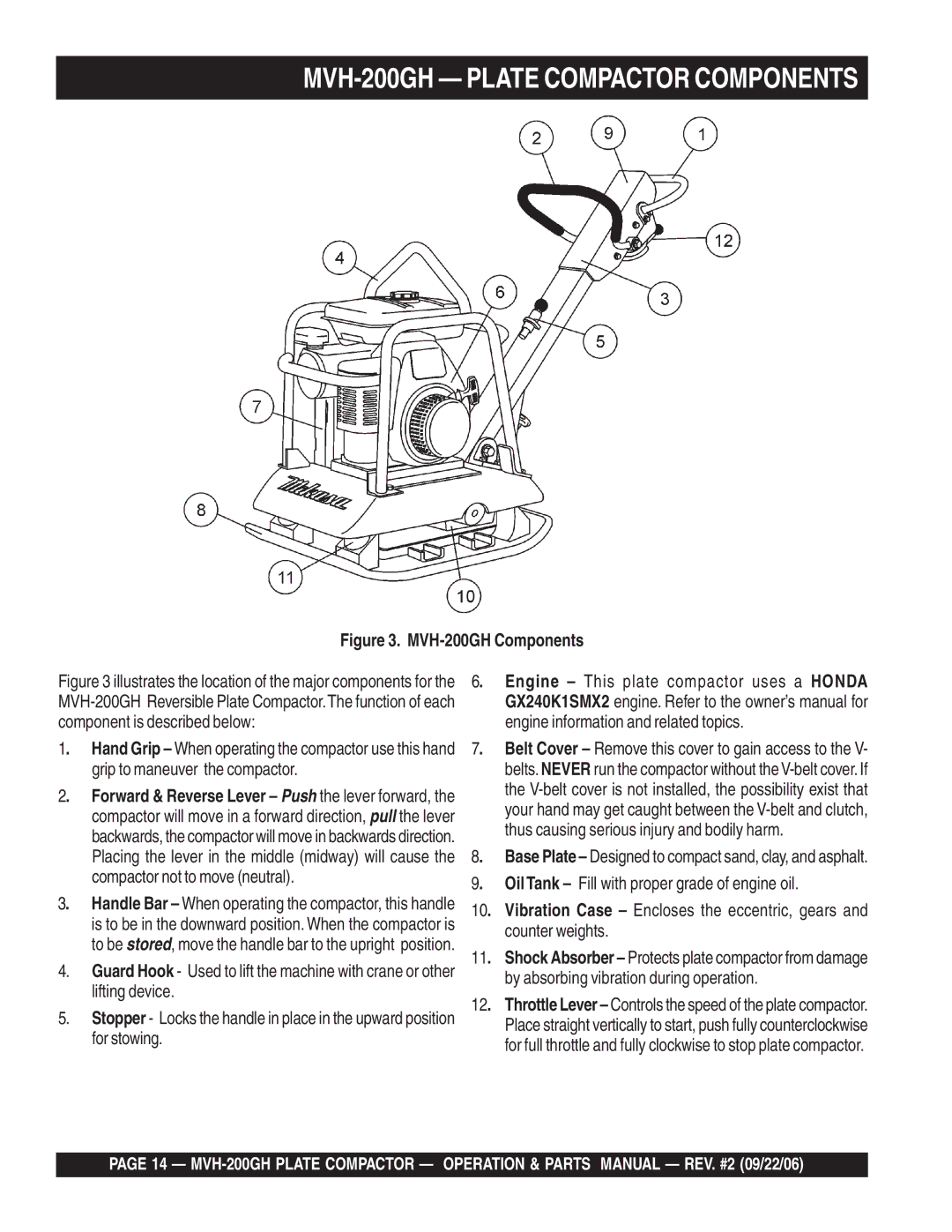

MVH-200GH — PLATE COMPACTOR COMPONENTS

Figure 3. MVH-200GH Components

Figure 3 illustrates the location of the major components for the MVH-200GH Reversible Plate Compactor.The function of each component is described below:

1. | Hand Grip – When operating the compactor use this hand |

| grip to maneuver the compactor. |

2. | Forward & Reverse Lever – Push the lever forward, the |

| compactor will move in a forward direction, pull the lever |

| backwards, the compactor will move in backwards direction. |

| Placing the lever in the middle (midway) will cause the |

| compactor not to move (neutral). |

3. | Handle Bar – When operating the compactor, this handle |

| is to be in the downward position. When the compactor is |

| to be stored, move the handle bar to the upright position. |

4.Guard Hook - Used to lift the machine with crane or other lifting device.

5.Stopper - Locks the handle in place in the upward position for stowing.

6. Engine – This plate compactor uses a HONDA GX240K1SMX2 engine. Refer to the owner’s manual for

| engine information and related topics. |

7. | Belt Cover – Remove this cover to gain access to the V- |

| belts. NEVER run the compactor without the |

| the |

| your hand may get caught between the |

| thus causing serious injury and bodily harm. |

8. | Base Plate – Designed to compact sand, clay, and asphalt. |

9. | OilTank – Fill with proper grade of engine oil. |

10. Vibration Case – Encloses the eccentric, gears and counter weights.

11. Shock Absorber – Protects plate compactor from damage by absorbing vibration during operation.

12. Throttle Lever – Controls the speed of the plate compactor. Place straight vertically to start, push fully counterclockwise for full throttle and fully clockwise to stop plate compactor.

PAGE 14 —