WM120PH Series

Proposition 65 Warning

SILICOSIS/RESPIRATORY Warnings Silicosis Warning

Respiratory Hazards

Table of Contents

WM120PH/SH Hydraulic Mixer

Parts Ordering Procedures

Ordering parts has never been easier

Safety

Safety Message Alert Symbols

Hazard Symbols

Foryour Safety and Safety of Others

Safety

General Safety

Rules and Regulations

Maintenance Safety

Transporting

Emergencies

Towing Safety Precautions

Towing Guidelines

Safety Chain Connection

TOW BAR to Mixer Connection

Specifications

Specifications Mixer

Dimensions

Dimensions

General Information

Application

Mixer Components

Mixer COMPONENTS/HYDRAULIC Components

Hydraulic Components

Muffler Used to reduce noise and emissions

Engine Components

Initial Servicing

Do not operate electric motor in an explosive environment

Electric Motor Components

Electric Motor

Paddle Blade Adjustment Steel Drum

Adjust paddles as shown in Figure

Paddle Blade Adjustment Poly Drum

Paddle Blade Adjustment Poly Drum

Inspection

Before Starting

Engine OIL Check

Fuel Check

Hydraulic OIL

Hydraulic Hoses

Grease Fittings Bearings

Blade Check

Initial START-UP Gasoline

Starting the Engine

Mixing

Initial START-UP ELECTRIC/OPERATION

Starting the Electric Motor

Dumping Hydraulic

Operation

Dumping Manual

Push the start/stop switch inward to stop the engine

SHUT-DOWN

Stoppingthe Mixer Gasoline Engine

Stoppingthe Mixer Electric Motor

Maintenance Engine

Engine Maintenance Schedule

Maintenance

Engine AIR Cleaner

Install drain bolt with sealing washer and tighten securely

Engine OIL

Maintenance Mixer

Ball Socket and Clamp Face Maintenance

Drum Head Seals

Wheel Bearings

TIRES/WHEELS/LUG Nuts

TIRESWEAR/INFLATION

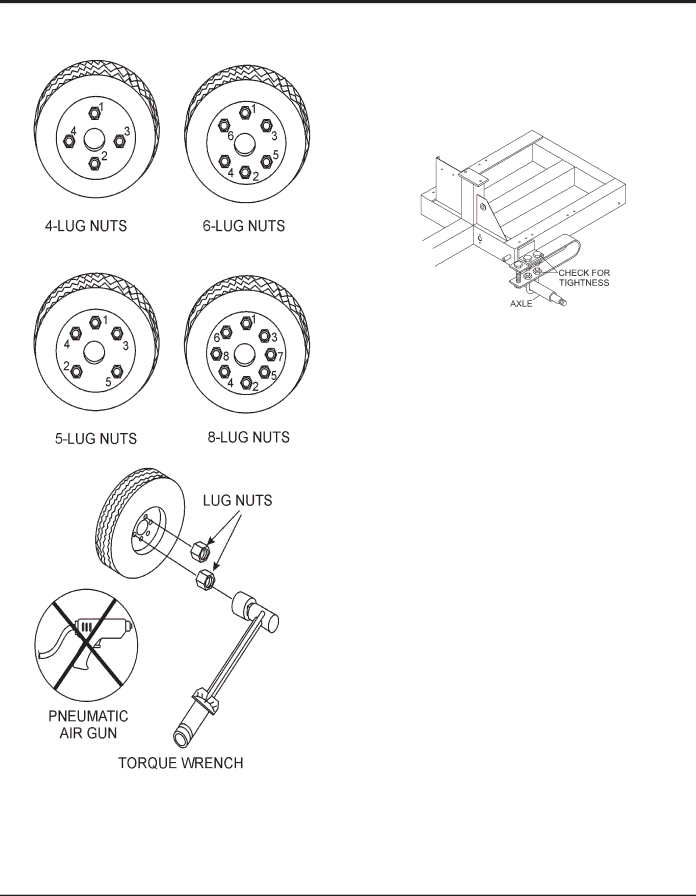

LUG NUT Torque Requirements

NEVER! use an pneumatic air gun to tighten wheel lug nuts

Mixer Cleaning

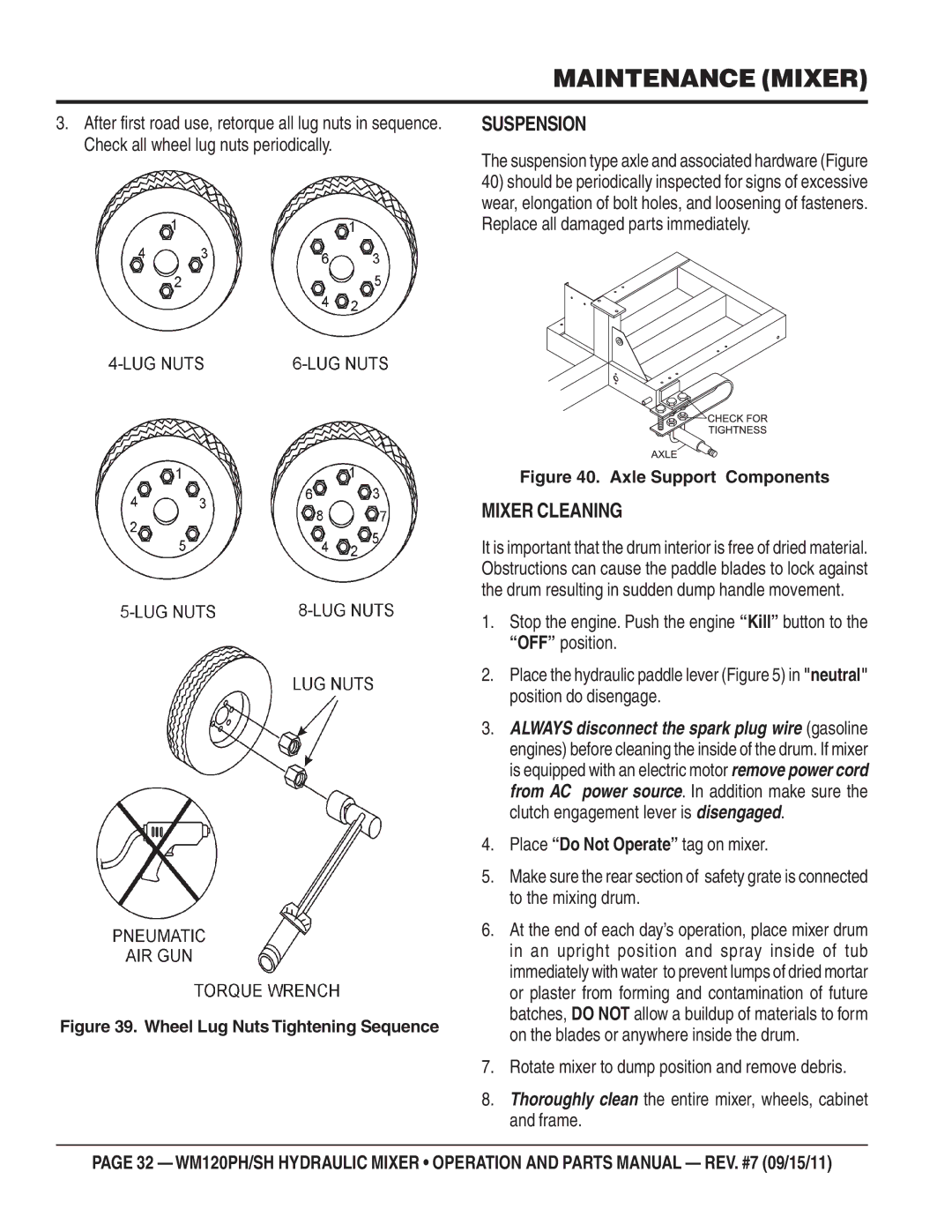

Suspension

Maintenance MIXER/STORAGE

Mixer Storage

Troubleshooting Engine

Engine Troubleshooting

White

Solution

Troubleshooting MIXER/ELECTRIC Motor

Symptom

Wiring Diagram Electric Motor

Electric Motor Wiring Diagram

Hydraulic System Diagram

Hydraulic System Diagram

Page

Sample Parts List

Explanation of Code in Remarks Column

Suggested Spare Parts

WM120PS 1TO 3 Units WM120PS 5TO 10 Units

Nameplate and Decals

Part Name

Remarks

Paddle Blades Assy

TOW END12

Part Name QTY Remarks

Plastic Mixing Drum Assy

Bearing Housing

GRATE, Movable

GRATE, Stationary

Manual Dump only

Steel Drum ASSY. Manual

Bearing Housing Front

Bearing HOUSING, Rear

NUT, Nyloc 3/8

Steel DRUM, Manual

Steel Drum ASSY. Hydraulic

Front

Part Name QTY. Remarks

Moveable Grate

BAR, Grate

Steel DRUM, Hydraulic

Paddle Shaft ASSY. PLASTIC/STEEL

SPACER, Thin Seal

Spring

SEAL, Bearing 1-1/2

Bearing

Hydraulic Assy

ARM, Motor Torque

CAP, Spring Mount

HOSE, Pump Output

STRAINER, in Line

January 1996 April

Frame 1 Assy

LUG HUB and Wheel 1-1/16 Axle Spindle

Part Name QTY Remark

Frame 2 Assy

April 1999 MAY

Safety Chain ASM

Contact Unit Sales Dept

No Longer Available

See Frame 3 Assy

MAY 2000 and Above

Frame 3 Assy

GE21000 and Above

LUG NUT

HLC-1

HPC-1

HBC-1

Plastic Engine Cover Assy

January 1996 to MAY

Hinge PIN

Small Hinge Plate

Large Hinge Plate

Lock Washer 1/4

Steel Engine Cover Assy

GE 210001 and Above

Flat Washer 3/8

Hinge

Rubber Latch Assy

Single PHASE, 5 HP Electric Motor Assy

Switch ASSY, 5HP 1PH

Wire Connector

Conduit Connector

Connector

Three PHASE, 5 HP Electric Motor Assy

MOTOR, ELECTRIC, 5HP 3PH

Switch ASSY, 5HP 3PH

Prong Plug

Honda Engine Assy

SWITCH, PUSH-PULL W/O Knob

ENGINE, Honda 13HP GX390U1QA2

TUBE, Exhaust

Plate

Honda GX390K1QA2/GX390U1QA2 AIR Cleaner Assy

COVER, AIR Cleaner

GROMMET, AIR Cleaner

COLLAR, AIR Cleaner

Collar B, AIR Cleaner

Honda GX390K1QA2/GX390U1QA2 Camshaft Assy

Camshaft Assembly

SPRING, Weight Return

ROD, Push

LIFTER, Valve

Honda GX390K1QA2/GX390U1QA2 Piston Assy

BOLT, Connecting ROD

Ring SET, Piston STD

Piston Standard

Piston OS 0.25, Optional

Honda GX390K1QA2/GX390U1QA2 Crankcase Cover Assy

WEIGHT, Governor

HOLDER, Governor Weight

PIN, Governor Weight

GASKET, Case Cover

Honda GX390K1QA2/GX390U1QA2 Crankshaft Assy

WEIGHT, Balancer

BEARING, Radial Ball 6207S

Honda GX390K1QA2/GX390U1QA2 Cylinder Barrel Assy

BOLT, Flange 6X12 CT200

SHAFT, Governor ARM

BOLT, Drain Plug 12 X

Honda GX390K1QA2/GX390U1QA2 Cylinder Head Assy

GUIDE, Valve OS Optional

GUIDE, EX. Valve OS Optional

CLIP, Valve Guide

GASKET, Cylinder Head

Honda GX390K1QA2/GX390U1QA2 FAN Cover Assy

CLIP, Wire Harness

CLIP, Tube

COVER, FAN *R280*, RED

Shroud

Honda GX390K1QA2/GX390U1QA2 Flywheel Assy

FAN, Cooling

Flywheel

Honda GX390K1QA2/GX390U1QA2 Ignition Coil Assy

CLIP, Harness

GROMMET, Wire

WIRE, Stop Switch 430MM

Honda GX390K1QA2/GX390U1QA2 Carburetor Assy

Carburetor Assy

Includes Item W

Valve SET, Float

Float SET

Honda GX390K1QA2/GX390U1QA2 Muffler Assy

Muffler 100DB

PROTECTOR, Muffler

PROTECTOR, Exhaust Pipe

PIPE, Exhaust

Honda GX390K1QA2/GX390U1QA2 Recoil Starter Assy

PULLEY, Recoil Starter

RATCHET, Starter

SPRING, Friction

SPRING, Starter Return

Honda GX390K1QA2/GX390U1QA2- Control Assy

ARM, Governor

ROD, Governor

SPRING, Governor

SPRING, Throttle Return

Honda GX390K1QA2/GX390U1QA2 Fuel Tank Assy

RUBBER, Supporter 107MM

JOINT, Fuel Tank

TANK, Fuel *NH31

TANK, Fuel *NH1

Honda GX390K1QA2 Gasket KIT Assy

061A1Z6700

11381ZE3800

12251ZF6W00

Honda GX390K1QA2/GX390U1QA2 Labels Assy

MARK, Operator

MARK,, Throttle Indication

LABEL, Caution

MARK, Choke Orange

Terms and Conditions of Sale Parts

Freight Policy

Page

HERE’S HOW to GET Help