TYPICAL WIRING DIAGRAMS

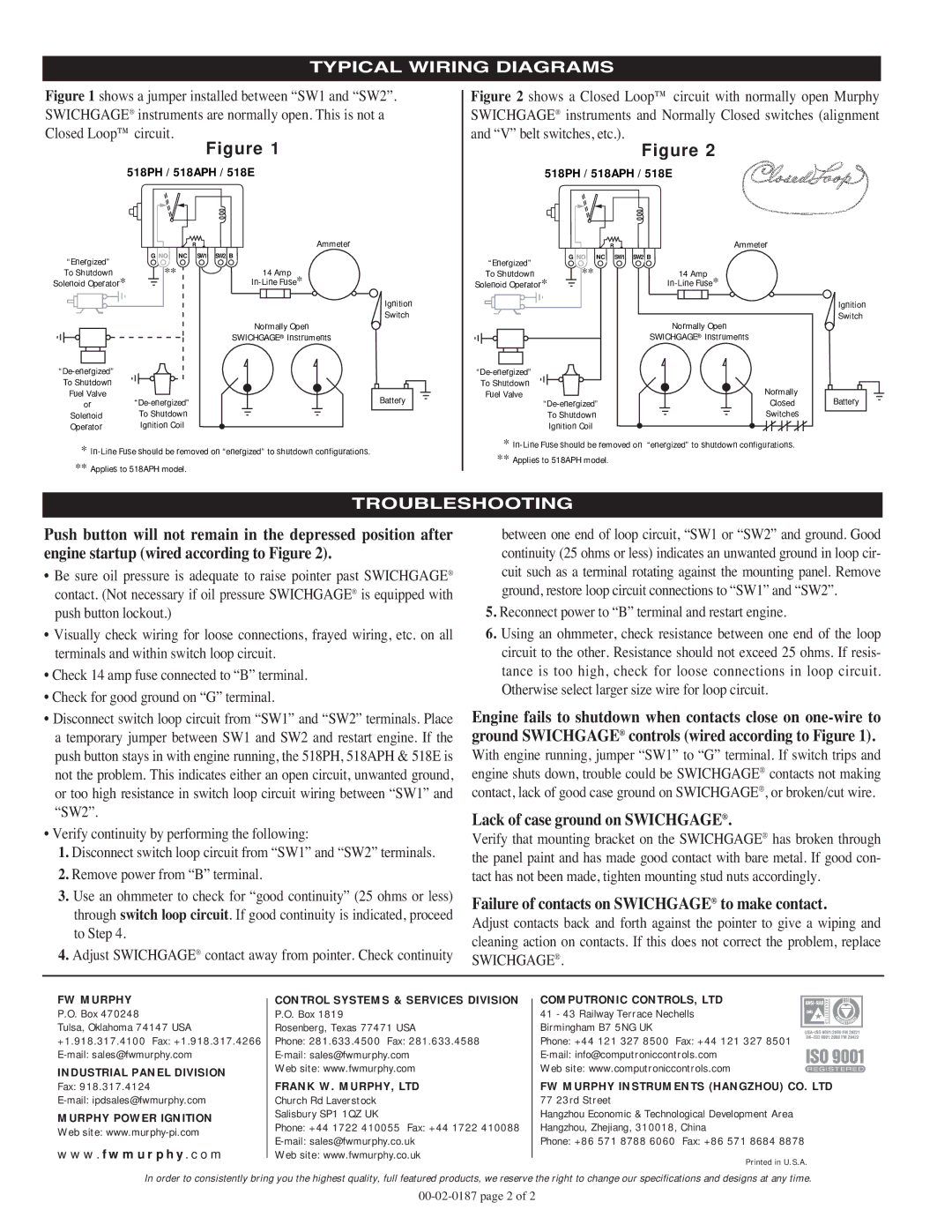

Figure 1 shows a jumper installed between “SW1 and “SW2”. SWICHGAGE® instruments are normally open. This is not a Closed Loop™ circuit.

Figure 1

518PH / 518APH / 518E

| R | Ammeter | |

“Energized” | G NO NC SW1 | SW2 B | |

** | 14 Amp | ||

To Shutdown | |||

Solenoid Operator* |

| ||

|

| Ignition | |

|

| Switch | |

|

| Normally Open | |

|

| SWICHGAGE® Instruments | |

|

| ||

To Shutdown |

|

| |

Fuel Valve | Battery | ||

or | |||

Solenoid | To Shutdown |

| |

Operator | Ignition Coil |

|

*

**Applies to 518APH model.

Figure 2 shows a Closed Loop™ circuit with normally open Murphy SWICHGAGE® instruments and Normally Closed switches (alignment and “V” belt switches, etc.).

Figure 2

518PH / 518APH / 518E

| R | Ammeter |

|

“Energized” | G NO NC SW1 | SW2 B |

|

** | 14 Amp |

| |

To Shutdown |

| ||

Solenoid Operator* |

| ||

|

|

| Ignition |

|

| Normally Open | Switch |

|

|

| |

|

| SWICHGAGE® Instruments |

|

|

|

| |

To Shutdown |

| Normally |

|

Fuel Valve |

| Battery | |

| Closed | ||

| To Shutdown | Switches |

|

| Ignition Coil |

|

|

*

**Applies to 518APH model.

TROUBLESHOOTING

Push button will not remain in the depressed position after engine startup (wired according to Figure 2).

•Be sure oil pressure is adequate to raise pointer past SWICHGAGE® contact. (Not necessary if oil pressure SWICHGAGE® is equipped with push button lockout.)

•Visually check wiring for loose connections, frayed wiring, etc. on all terminals and within switch loop circuit.

•Check 14 amp fuse connected to “B” terminal.

•Check for good ground on “G” terminal.

•Disconnect switch loop circuit from “SW1” and “SW2” terminals. Place a temporary jumper between SW1 and SW2 and restart engine. If the push button stays in with engine running, the 518PH, 518APH & 518E is not the problem. This indicates either an open circuit, unwanted ground, or too high resistance in switch loop circuit wiring between “SW1” and “SW2”.

•Verify continuity by performing the following:

1.Disconnect switch loop circuit from “SW1” and “SW2” terminals.

2.Remove power from “B” terminal.

3.Use an ohmmeter to check for “good continuity” (25 ohms or less) through switch loop circuit. If good continuity is indicated, proceed to Step 4.

4.Adjust SWICHGAGE® contact away from pointer. Check continuity

between one end of loop circuit, “SW1 or “SW2” and ground. Good continuity (25 ohms or less) indicates an unwanted ground in loop cir- cuit such as a terminal rotating against the mounting panel. Remove ground, restore loop circuit connections to “SW1” and “SW2”.

5.Reconnect power to “B” terminal and restart engine.

6.Using an ohmmeter, check resistance between one end of the loop circuit to the other. Resistance should not exceed 25 ohms. If resis- tance is too high, check for loose connections in loop circuit. Otherwise select larger size wire for loop circuit.

Engine fails to shutdown when contacts close on

With engine running, jumper “SW1” to “G” terminal. If switch trips and engine shuts down, trouble could be SWICHGAGE® contacts not making contact, lack of good case ground on SWICHGAGE®, or broken/cut wire.

Lack of case ground on SWICHGAGE®.

Verify that mounting bracket on the SWICHGAGE® has broken through the panel paint and has made good contact with bare metal. If good con- tact has not been made, tighten mounting stud nuts accordingly.

Failure of contacts on SWICHGAGE® to make contact.

Adjust contacts back and forth against the pointer to give a wiping and cleaning action on contacts. If this does not correct the problem, replace

SWICHGAGE®.

FW MURPHY

P.O. Box 470248

Tulsa, Oklahoma 74147 USA +1.918.317.4100 Fax: +1.918.317.4266

INDUSTRIAL PANEL DIVISION

Fax: 918.317.4124

MURPHY POWER IGNITION

Web site:

www.fwmurphy.com

CONTROL SYSTEMS & SERVICES DIVISION |

| COMPUTRONIC CONTROLS, LTD |

|

|

|

|

|

|

|

|

| ||

P.O. Box 1819 |

| 41 - 43 Railway Terrace Nechells |

|

|

|

|

Rosenberg, Texas 77471 USA |

| Birmingham B7 5NG UK |

|

|

|

|

|

|

|

|

| ||

Phone: 281.633.4500 Fax: 281.633.4588 |

| Phone: +44 121 327 8500 Fax: +44 121 327 8501 | ||||

|

|

| ||||

|

| |||||

Web site: www.fwmurphy.com |

| Web site: www.computroniccontrols.com |

|

| ||

FRANK W. MURPHY, LTD |

| FW MURPHY INSTRUMENTS (HANGZHOU) CO. LTD | ||||

Church Rd Laverstock |

| 77 23rd Street | ||||

Salisbury SP1 1QZ UK |

| Hangzhou Economic & Technological Development Area | ||||

Phone: +44 1722 410055 Fax: +44 1722 410088 |

| Hangzhou, Zhejiang, 310018, China | ||||

| Phone: +86 571 8788 6060 Fax: +86 571 8684 8878 | |||||

Web site: www.fwmurphy.co.uk |

| Printed in U.S.A. | ||||

| ||||||

|

| |||||

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.