BN204 Series specifications

The Murphy BN204 Series represents a significant advancement in monitoring technology for engines and equipment, catering to industries that require efficient oversight of operational parameters. Designed with durability and versatility in mind, this series is ideal for use in harsh environments, making it a perfect choice for industries such as construction, agriculture, and transportation.At the heart of the BN204 Series are its comprehensive monitoring capabilities, specifically focused on monitoring engine-critical parameters such as temperature, pressure, and fluid levels. This series features advanced sensors that can detect anomalies in real-time, allowing operators to address potential issues before they escalate into costly failures. With the integration of these technologies, the BN204 ensures optimal performance and longevity of equipment.

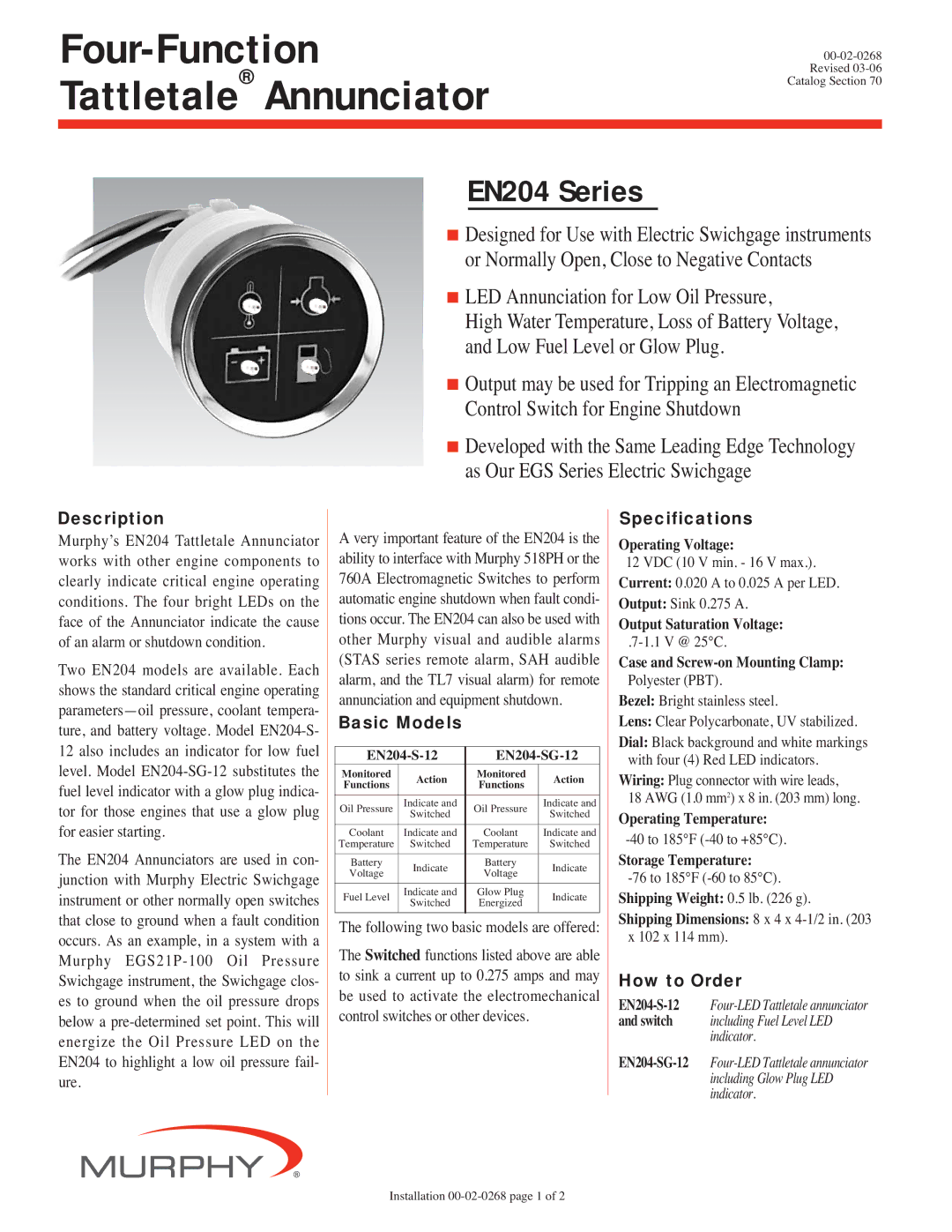

One of the primary features of the BN204 Series is its user-friendly interface, which allows operators to easily access data readings and make quick adjustments as necessary. The display is designed to provide clear visibility, even in low light conditions, ensuring that users can monitor their equipment effectively at all times. Additionally, the BN204 can be customized according to specific application requirements, with various models available to suit different operational needs.

The BN204 Series employs robust construction materials resistant to vibration, moisture, and extreme temperatures, which significantly enhances its reliability and extends its lifespan. Moreover, its modular design allows for easier integration into existing systems, reducing the time and cost associated with installation and maintenance.

In terms of communications technology, the BN204 Series is equipped with modern connectivity options that enable seamless integration with remote monitoring systems. This allows for real-time data transmission, enabling operators to monitor equipment performance from virtually anywhere. Such capabilities are vital for fleet management and in applications where downtime must be minimized.

In summary, the Murphy BN204 Series stands out due to its advanced monitoring technologies, user-centric design, and rugged construction. The series not only enhances operational efficiency and safety but also provides peace of mind to operators by ensuring that critical parameters are continuously monitored and that any issues are swiftly addressed. As industries evolve, the BN204 Series remains a trusted solution for maximizing equipment performance and reliability.