BASIC OPERATION

DF755EX

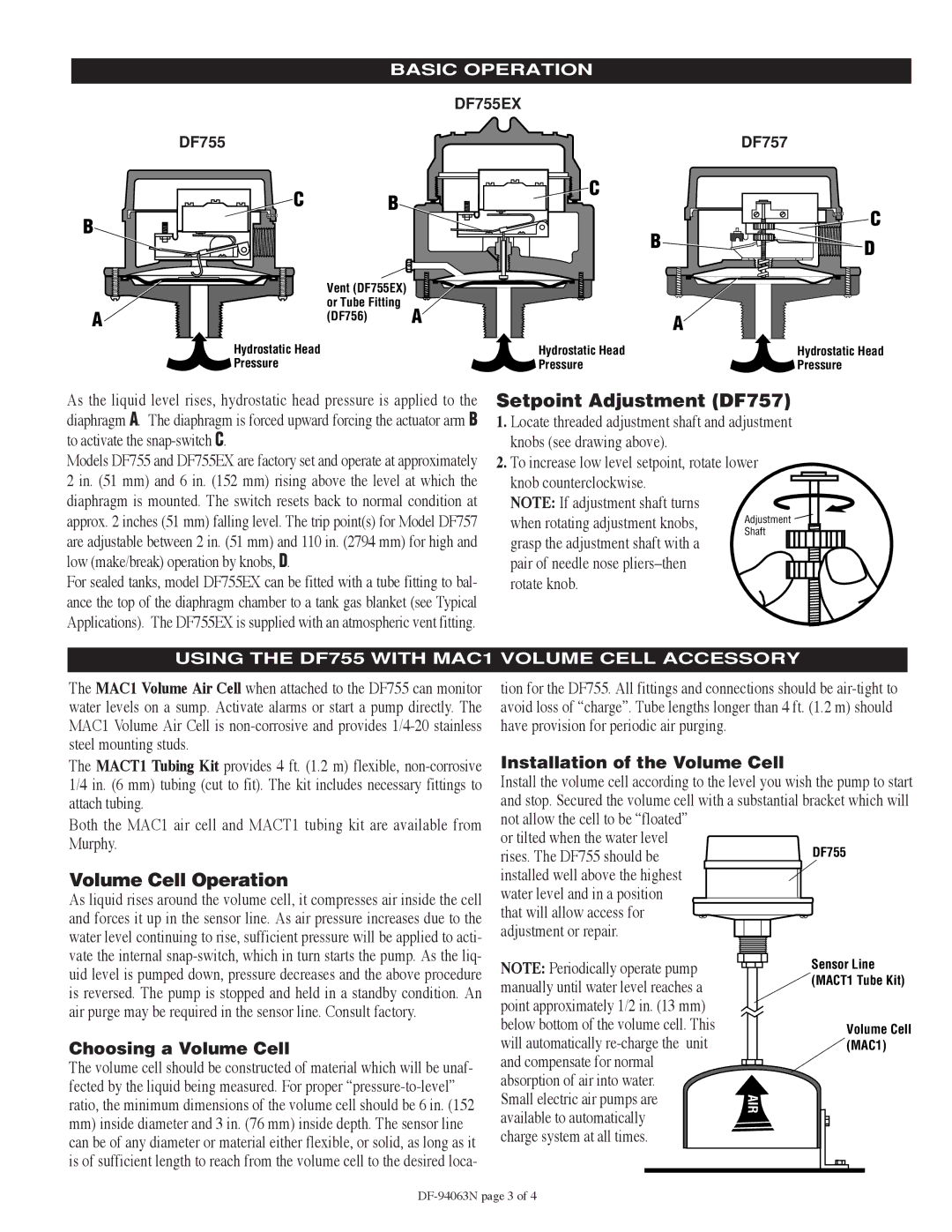

DF755 | DF757 |

B![]()

![]()

A![]()

C B

Vent (DF755EX) or Tube Fitting

(DF756) A

Hydrostatic Head

Pressure

C |

|

|

| B | C |

| D | |

|

| |

|

| A |

Hydrostatic Head |

| Hydrostatic Head |

Pressure |

| Pressure |

As the liquid level rises, hydrostatic head pressure is applied to the diaphragm A. The diaphragm is forced upward forcing the actuator arm B to activate the

Models DF755 and DF755EX are factory set and operate at approximately 2 in. (51 mm) and 6 in. (152 mm) rising above the level at which the diaphragm is mounted. The switch resets back to normal condition at approx. 2 inches (51 mm) falling level. The trip point(s) for Model DF757 are adjustable between 2 in. (51 mm) and 110 in. (2794 mm) for high and low (make/break) operation by knobs, D.

For sealed tanks, model DF755EX can be fitted with a tube fitting to bal- ance the top of the diaphragm chamber to a tank gas blanket (see Typical Applications). The DF755EX is supplied with an atmospheric vent fitting.

Setpoint Adjustment (DF757)

1.Locate threaded adjustment shaft and adjustment knobs (see drawing above).

2.To increase low level setpoint, rotate lower

knob counterclockwise. NOTE: If adjustment shaft turns

when rotating adjustment knobs, | Adjustment | |||||||||

Shaft |

|

|

|

|

|

|

|

|

| |

grasp the adjustment shaft with a |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

pair of needle nose |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

rotate knob. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

USING THE DF755 WITH MAC1 VOLUME CELL ACCESSORY

The MAC1 Volume Air Cell when attached to the DF755 can monitor water levels on a sump. Activate alarms or start a pump directly. The MAC1 Volume Air Cell is

The MACT1 Tubing Kit provides 4 ft. (1.2 m) flexible,

Both the MAC1 air cell and MACT1 tubing kit are available from Murphy.

Volume Cell Operation

As liquid rises around the volume cell, it compresses air inside the cell and forces it up in the sensor line. As air pressure increases due to the water level continuing to rise, sufficient pressure will be applied to acti- vate the internal

tion for the DF755. All fittings and connections should be

Installation of the Volume Cell

Install the volume cell according to the level you wish the pump to start and stop. Secured the volume cell with a substantial bracket which will not allow the cell to be “floated”

or tilted when the water level

rises. The DF755 should beDF755 installed well above the highest

water level and in a position that will allow access for adjustment or repair.

uid level is pumped down, pressure decreases and the above procedure is reversed. The pump is stopped and held in a standby condition. An air purge may be required in the sensor line. Consult factory.

Choosing a Volume Cell

The volume cell should be constructed of material which will be unaf- fected by the liquid being measured. For proper

mm)inside diameter and 3 in. (76 mm) inside depth. The sensor line can be of any diameter or material either flexible, or solid, as long as it is of sufficient length to reach from the volume cell to the desired loca-

NOTE: Periodically operate pump manually until water level reaches a point approximately 1/2 in. (13 mm) below bottom of the volume cell. This will automatically

Small electric air pumps are available to automatically charge system at all times.

AIR

Sensor Line (MACT1 Tube Kit)

Volume Cell (MAC1)