Using the Adjustable Clutch

This tool has an adjustable clutch for driving different types of screws into different materi- als. When properly adjusted, the clutch will slip at a preset torque to prevent driving the screw too deep and to prevent damage to the screw or tool.

To adjust the clutch, turn the clutch adjusting ring so that the desired setting

Fig. 2

Driving

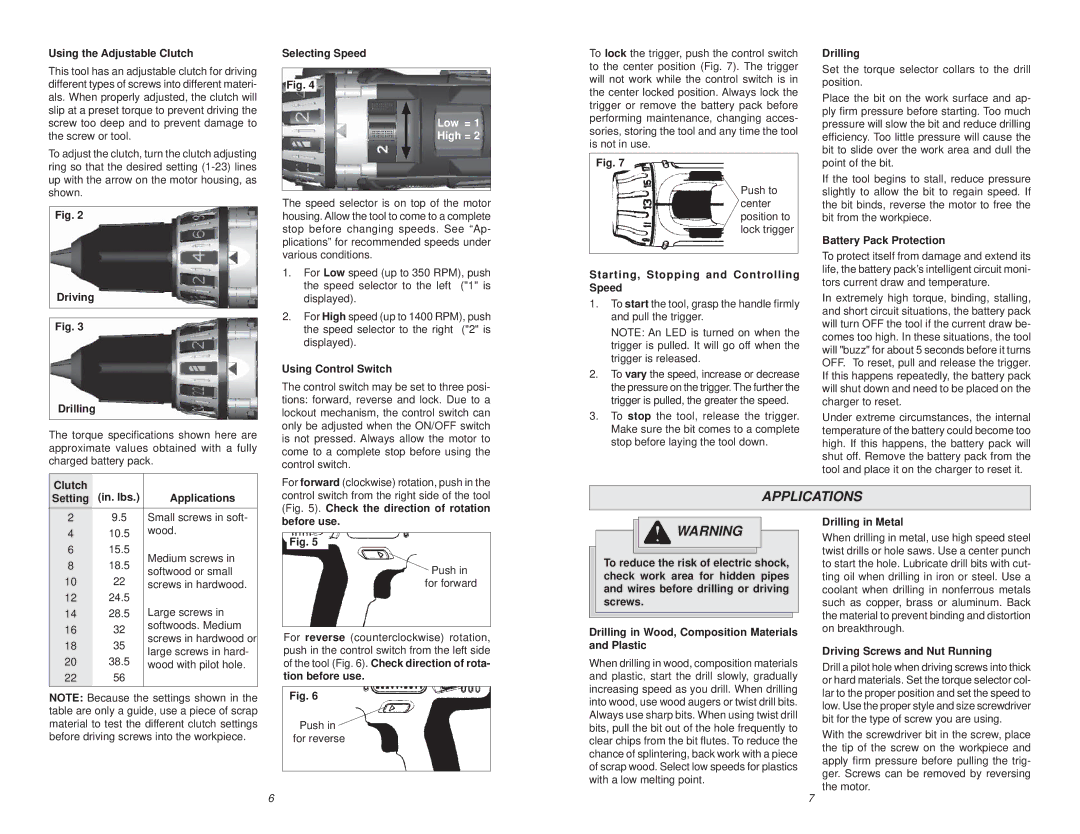

Fig. 3

Drilling

The torque specifications shown here are approximate values obtained with a fully charged battery pack.

Selecting Speed

Fig. 4

Low = 1

High = 2

The speed selector is on top of the motor housing. Allow the tool to come to a complete stop before changing speeds. See “Ap- plications” for recommended speeds under various conditions.

1.For Low speed (up to 350 RPM), push the speed selector to the left ("1" is displayed).

2.For High speed (up to 1400 RPM), push the speed selector to the right ("2" is displayed).

Using Control Switch

The control switch may be set to three posi- tions: forward, reverse and lock. Due to a lockout mechanism, the control switch can only be adjusted when the ON/OFF switch is not pressed. Always allow the motor to come to a complete stop before using the control switch.

To lock the trigger, push the control switch to the center position (Fig. 7). The trigger will not work while the control switch is in the center locked position. Always lock the trigger or remove the battery pack before performing maintenance, changing acces- sories, storing the tool and any time the tool is not in use.

Fig. 7

Push to center position to lock trigger

Starting, Stopping and Controlling Speed

1.To start the tool, grasp the handle firmly and pull the trigger.

NOTE: An LED is turned on when the trigger is pulled. It will go off when the trigger is released.

2.To vary the speed, increase or decrease the pressure on the trigger. The further the trigger is pulled, the greater the speed.

3.To stop the tool, release the trigger. Make sure the bit comes to a complete stop before laying the tool down.

Drilling

Set the torque selector collars to the drill position.

Place the bit on the work surface and ap- ply firm pressure before starting. Too much pressure will slow the bit and reduce drilling efficiency. Too little pressure will cause the bit to slide over the work area and dull the point of the bit.

If the tool begins to stall, reduce pressure slightly to allow the bit to regain speed. If the bit binds, reverse the motor to free the bit from the workpiece.

Battery Pack Protection

To protect itself from damage and extend its life, the battery pack’s intelligent circuit moni- tors current draw and temperature.

In extremely high torque, binding, stalling, and short circuit situations, the battery pack will turn OFF the tool if the current draw be- comes too high. In these situations, the tool will "buzz" for about 5 seconds before it turns OFF. To reset, pull and release the trigger. If this happens repeatedly, the battery pack will shut down and need to be placed on the charger to reset.

Under extreme circumstances, the internal temperature of the battery could become too high. If this happens, the battery pack will shut off. Remove the battery pack from the tool and place it on the charger to reset it.

Clutch |

|

Setting (in. lbs.) | Applications |

For forward (clockwise) rotation, push in the control switch from the right side of the tool (Fig. 5). Check the direction of rotation

APPLICATIONS

2 | 9.5 | Small screws in soft- | |

4 | 10.5 | wood. | |

6 | 15.5 | Medium screws in | |

8 | 18.5 | ||

softwood or small | |||

10 | 22 | ||

screws in hardwood. | |||

12 | 24.5 | Large screws in | |

14 | 28.5 | ||

16 | 32 | softwoods. Medium | |

screws in hardwood or | |||

18 | 35 | ||

large screws in hard- | |||

20 | 38.5 | ||

wood with pilot hole. | |||

22 | 56 |

|

NOTE: Because the settings shown in the table are only a guide, use a piece of scrap material to test the different clutch settings before driving screws into the workpiece.

before use.

Fig. 5

Push in for forward

For reverse (counterclockwise) rotation, push in the control switch from the left side of the tool (Fig. 6). Check direction of rota- tion before use.

Fig. 6

Push in for reverse

![]()

![]()

![]() WARNING

WARNING

To reduce the risk of electric shock, check work area for hidden pipes and wires before drilling or driving screws.

Drilling in Wood, Composition Materials and Plastic

When drilling in wood, composition materials and plastic, start the drill slowly, gradually increasing speed as you drill. When drilling into wood, use wood augers or twist drill bits. Always use sharp bits. When using twist drill bits, pull the bit out of the hole frequently to clear chips from the bit flutes. To reduce the chance of splintering, back work with a piece of scrap wood. Select low speeds for plastics with a low melting point.

Drilling in Metal

When drilling in metal, use high speed steel twist drills or hole saws. Use a center punch to start the hole. Lubricate drill bits with cut- ting oil when drilling in iron or steel. Use a coolant when drilling in nonferrous metals such as copper, brass or aluminum. Back the material to prevent binding and distortion on breakthrough.

Driving Screws and Nut Running

Drill a pilot hole when driving screws into thick or hard materials. Set the torque selector col- lar to the proper position and set the speed to low. Use the proper style and size screwdriver bit for the type of screw you are using.

With the screwdriver bit in the screw, place the tip of the screw on the workpiece and apply firm pressure before pulling the trig- ger. Screws can be removed by reversing the motor.

6 | 7 |