|

|

|

|

|

|

30 | 7200 | 60’ | 35’ | 25’ | 10’ |

40 | 9600 | 30’ | 15’ | 10’ | * |

50 | 12000 | 15’ | * | * | * |

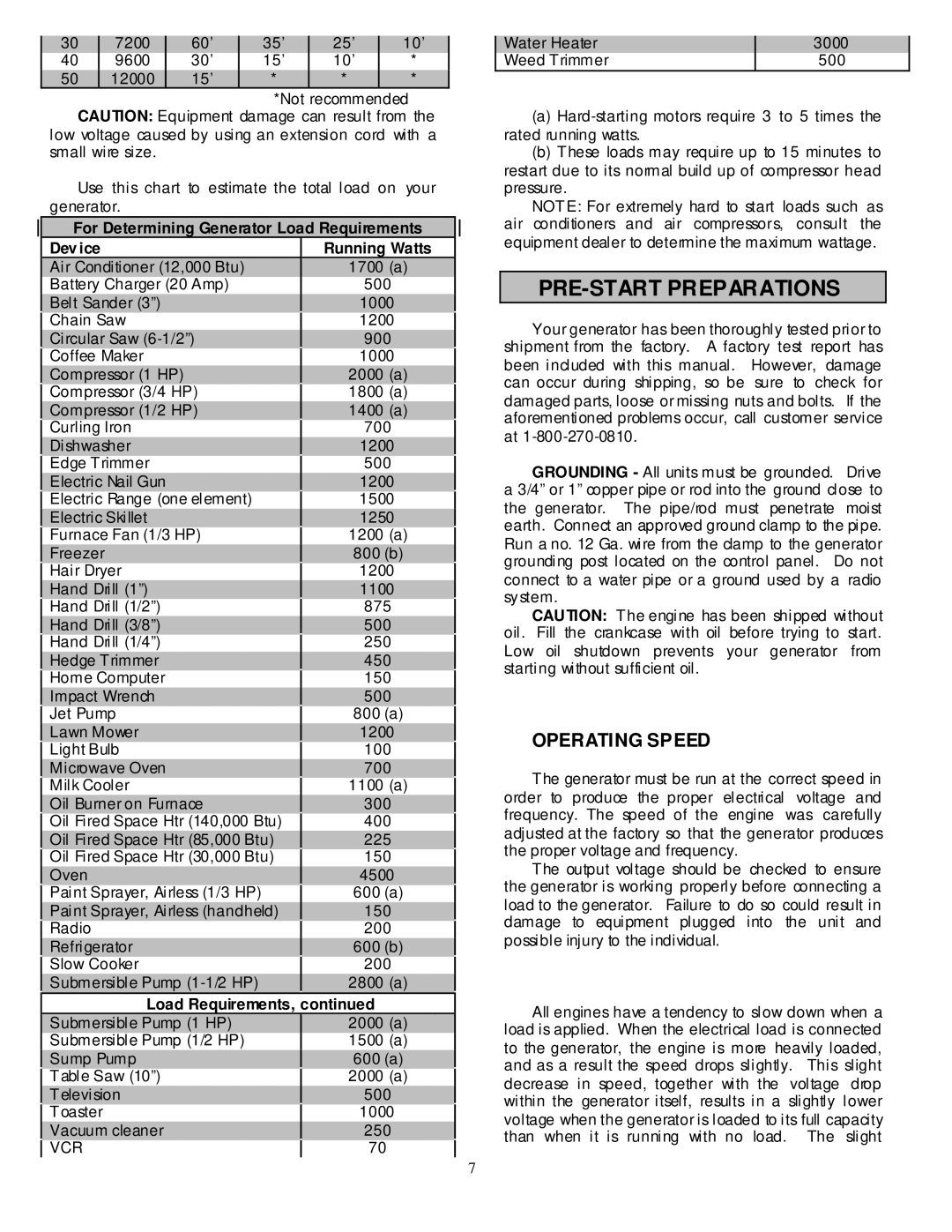

*Not recommended

CAUTION: Equipment damage can result from the low voltage caused by using an extension cord with a small wire size.

Use this chart to estimate the total load on your generator.

For Determining Generator Load Requirements

| Dev ice | Running Watts | |

| Air Conditioner (12,000 Btu) | 1700 (a) |

|

| Battery Charger (20 Amp) | 500 |

|

| Belt Sander (3”) | 1000 |

|

| Chain Saw | 1200 |

|

| Circular Saw | 900 |

|

| Coffee Maker | 1000 |

|

| Compressor (1 HP) | 2000 (a) |

|

| Compressor (3/4 HP) | 1800 (a) |

|

| Compressor (1/2 HP) | 1400 (a) |

|

| Curling Iron | 700 |

|

| Dishwasher | 1200 |

|

| Edge Trimmer | 500 |

|

| Electric Nail Gun | 1200 |

|

| Electric Range (one element) | 1500 |

|

| Electric Skillet | 1250 |

|

| Furnace Fan (1/3 HP) | 1200 (a) |

|

| Freezer | 800 (b) |

|

| Hair Dryer | 1200 |

|

| Hand Drill (1”) | 1100 |

|

| Hand Drill (1/2”) | 875 |

|

| Hand Drill (3/8”) | 500 |

|

| Hand Drill (1/4”) | 250 |

|

| Hedge Trimmer | 450 |

|

| Home Computer | 150 |

|

| Impact Wrench | 500 |

|

| Jet Pump | 800 (a) |

|

| Lawn Mower | 1200 |

|

| Light Bulb | 100 |

|

| Microwave Oven | 700 |

|

| Milk Cooler | 1100 (a) |

|

| Oil Burner on Furnace | 300 |

|

| Oil Fired Space Htr (140,000 Btu) | 400 |

|

| Oil Fired Space Htr (85,000 Btu) | 225 |

|

| Oil Fired Space Htr (30,000 Btu) | 150 |

|

| Oven | 4500 |

|

| Paint Sprayer, Airless (1/3 HP) | 600 (a) |

|

| Paint Sprayer, Airless (handheld) | 150 |

|

| Radio | 200 |

|

| Refrigerator | 600 (b) |

|

| Slow Cooker | 200 |

|

| Submersible Pump | 2800 (a) |

|

| Load Requirements, continued |

| |

| Submersible Pump (1 HP) | 2000 (a) |

|

| Submersible Pump (1/2 HP) | 1500 (a) |

|

| Sump Pump | 600 (a) |

|

| Table Saw (10”) | 2000 (a) |

|

| Television | 500 |

|

| Toaster | 1000 |

|

| Vacuum cleaner | 250 |

|

| VCR | 70 |

|

|

|

Water Heater | 3000 |

Weed Trimmer | 500 |

(a)

(b)These loads may require up to 15 minutes to restart due to its normal build up of compressor head pressure.

NOTE: For extremely hard to start loads such as air conditioners and air compressors, consult the equipment dealer to determine the maximum wattage.

PRE-START PREPARATIONS

Your generator has been thoroughly tested prior to shipment from the factory. A factory test report has been included with this manual. However, damage can occur during shipping, so be sure to check for damaged parts, loose or missing nuts and bolts. If the aforementioned problems occur, call customer service at

GROUNDING - All units must be grounded. Drive a 3/4” or 1” copper pipe or rod into the ground close to the generator. The pipe/rod must penetrate moist earth. Connect an approved ground clamp to the pipe. Run a no. 12 Ga. wire from the clamp to the generator grounding post located on the control panel. Do not connect to a water pipe or a ground used by a radio system.

CAUTION: The engine has been shipped without oil. Fill the crankcase with oil before trying to start. Low oil shutdown prevents your generator from starting without sufficient oil.

OPERATING SPEED

The generator must be run at the correct speed in order to produce the proper electrical voltage and frequency. The speed of the engine was carefully adjusted at the factory so that the generator produces the proper voltage and frequency.

The output voltage should be checked to ensure the generator is working properly before connecting a load to the generator. Failure to do so could result in damage to equipment plugged into the unit and possible injury to the individual.

All engines have a tendency to slow down when a load is applied. When the electrical load is connected to the generator, the engine is more heavily loaded, and as a result the speed drops slightly. This slight decrease in speed, together with the voltage drop within the generator itself, results in a slightly lower voltage when the generator is loaded to its full capacity than when it is running with no load. The slight

7