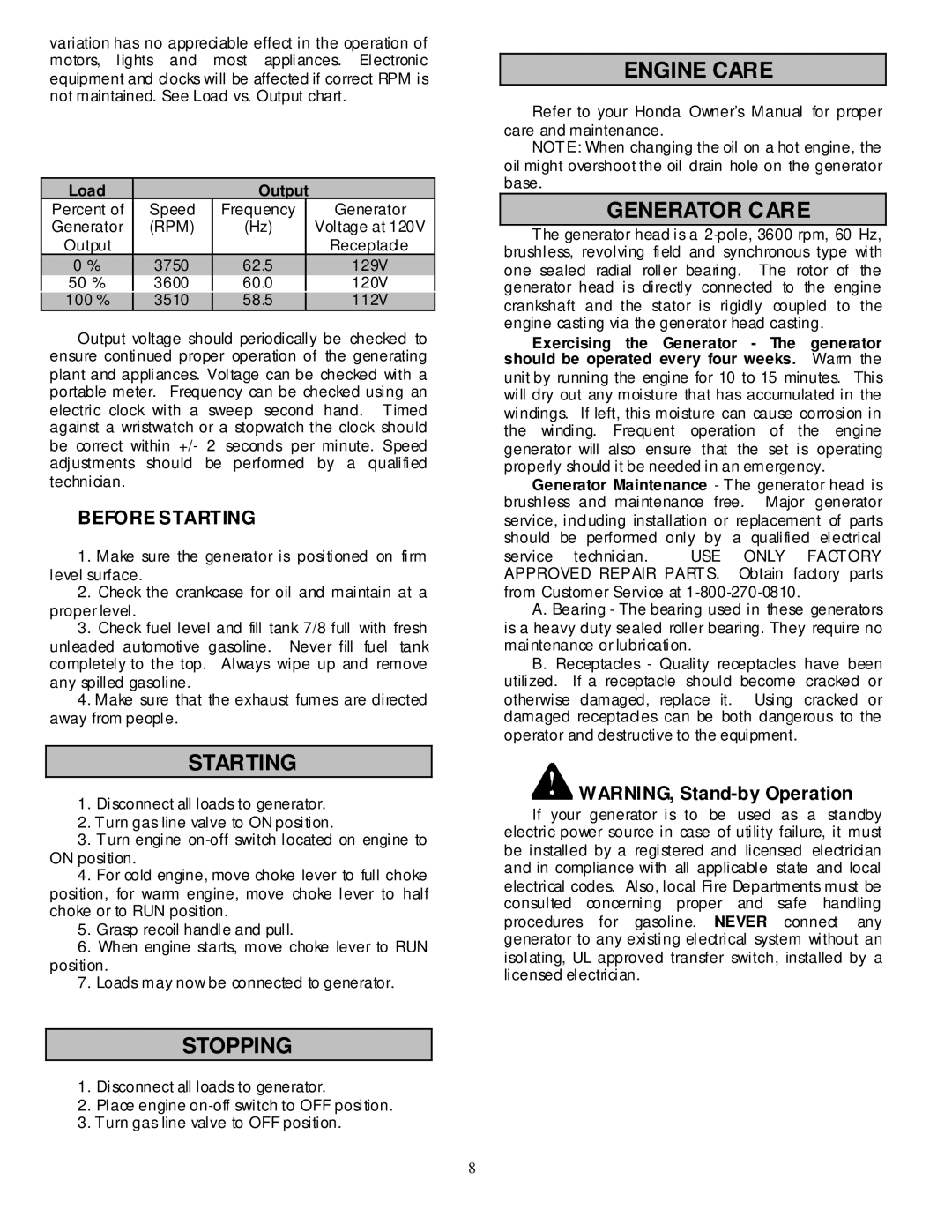

variation has no appreciable effect in the operation of motors, lights and most appliances. Electronic equipment and clocks will be affected if correct RPM is not maintained. See Load vs. Output chart.

Load |

| Output |

| |

Percent of | Speed | Frequency |

| Generator |

Generator | (RPM) | (Hz) |

| Voltage at 120V |

Output |

|

|

| Receptacle |

0 % | 3750 | 62.5 |

| 129V |

50 % | 3600 | 60.0 |

| 120V |

|

|

|

|

|

100 % | 3510 | 58.5 |

| 112V |

Output voltage should periodically be checked to ensure continued proper operation of the generating plant and appliances. Voltage can be checked with a portable meter. Frequency can be checked using an electric clock with a sweep second hand. Timed against a wristwatch or a stopwatch the clock should be correct within +/- 2 seconds per minute. Speed adjustments should be performed by a qualified technician.

BEFORE STARTING

1.Make sure the generator is positioned on firm level surface.

2.Check the crankcase for oil and maintain at a proper level.

3.Check fuel level and fill tank 7/8 full with fresh unleaded automotive gasoline. Never fill fuel tank completely to the top. Always wipe up and remove any spilled gasoline.

4.Make sure that the exhaust fumes are directed away from people.

STARTING

1.Disconnect all loads to generator.

2.Turn gas line valve to ON position.

3.Turn engine

ON position.

4.For cold engine, move choke lever to full choke position, for warm engine, move choke lever to half choke or to RUN position.

5.Grasp recoil handle and pull.

6.When engine starts, move choke lever to RUN position.

7.Loads may now be connected to generator.

STOPPING

1.Disconnect all loads to generator.

2.Place engine

3.Turn gas line valve to OFF position.

ENGINE CARE

Refer to your Honda Owner’s Manual for proper care and maintenance.

NOTE: When changing the oil on a hot engine, the oil might overshoot the oil drain hole on the generator base.

GENERATOR CARE

The generator head is a

Exercising the Generator - The generator should be operated every four weeks. Warm the

unit by running the engine for 10 to 15 minutes. This will dry out any moisture that has accumulated in the windings. If left, this moisture can cause corrosion in the winding. Frequent operation of the engine generator will also ensure that the set is operating properly should it be needed in an emergency.

Generator Maintenance - The generator head is brushless and maintenance free. Major generator service, including installation or replacement of parts should be performed only by a qualified electrical

service technician. USE ONLY FACTORY APPROVED REPAIR PARTS. Obtain factory parts from Customer Service at

A. Bearing - The bearing used in these generators is a heavy duty sealed roller bearing. They require no maintenance or lubrication.

B. Receptacles - Quality receptacles have been utilized. If a receptacle should become cracked or otherwise damaged, replace it. Using cracked or damaged receptacles can be both dangerous to the operator and destructive to the equipment.

![]()

![]()

![]()

![]()

![]() WARNING,

WARNING,

If your generator is to be used as a standby electric power source in case of utility failure, it must be installed by a registered and licensed electrician and in compliance with all applicable state and local electrical codes. Also, local Fire Departments must be consulted concerning proper and safe handling procedures for gasoline. NEVER connect any generator to any existing electrical system without an isolating, UL approved transfer switch, installed by a licensed electrician.

8