5. Replace upper spindle nut. Flange of upper spindle nut should be facing downward so that it seats itself in the center reinforcement hub on the grinding disc.

6. Push in spindle lock button (located on the back side of the metal gear hous- ing) and simultaneously tighten spindle nut with spanner wrench. Be sure to tighten nut securely.

You are now ready to begin operation of your Angle Grinder.

OPERATING YOUR GRINDER |

| |

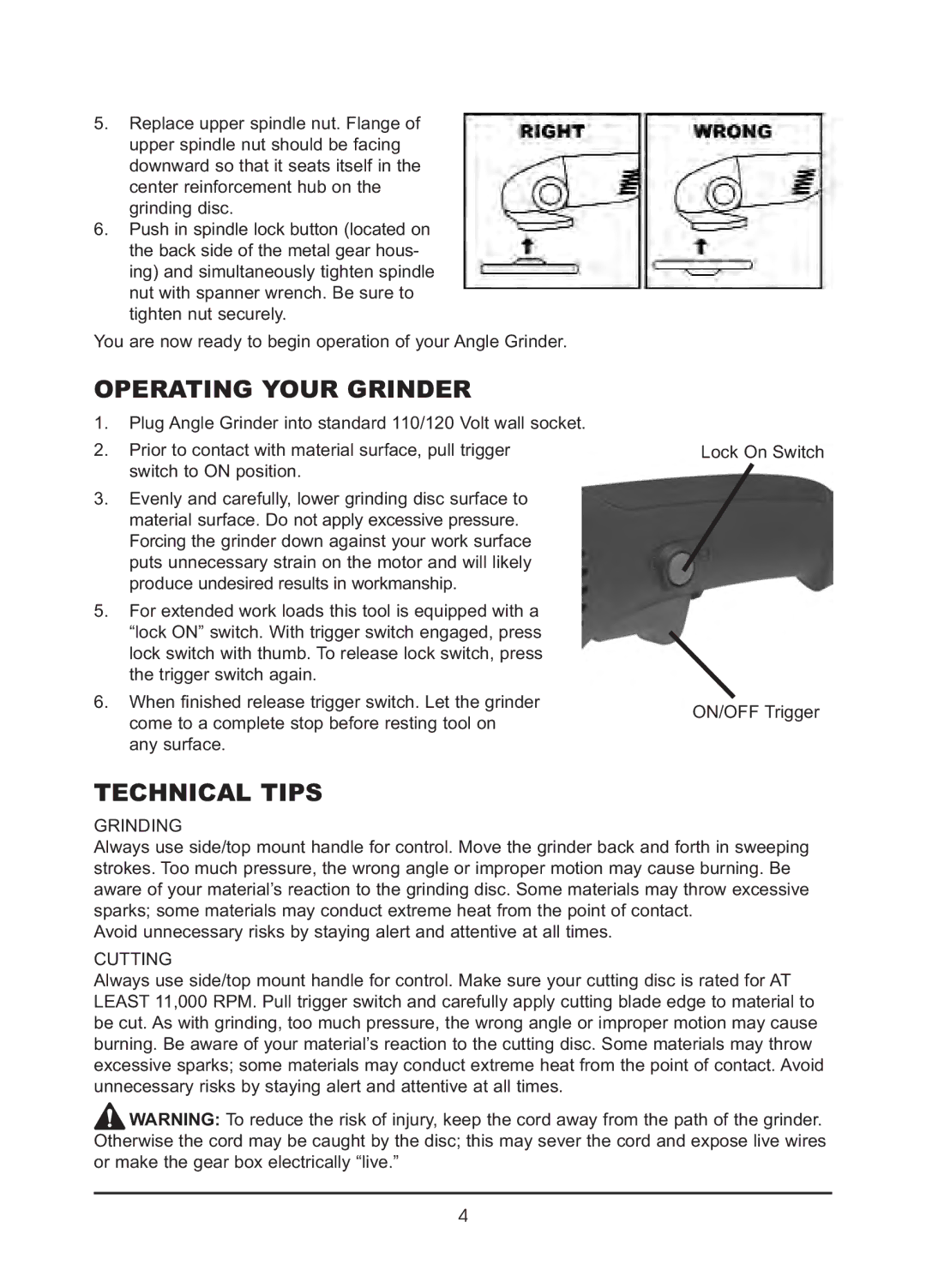

1. | Plug Angle Grinder into standard 110/120 Volt wall socket. | Lock On Switch |

2. | Prior to contact with material surface, pull trigger | |

3. | switch to ON position. |

|

Evenly and carefully, lower grinding disc surface to |

| |

| material surface. Do not apply excessive pressure. |

|

| Forcing the grinder down against your work surface |

|

| puts unnecessary strain on the motor and will likely |

|

5. | produce undesired results in workmanship. |

|

For extended work loads this tool is equipped with a |

| |

| “lock ON” switch. With trigger switch engaged, press |

|

| lock switch with thumb. To release lock switch, press |

|

6. | the trigger switch again. |

|

When finished release trigger switch. Let the grinder | ON/OFF Trigger | |

| come to a complete stop before resting tool on | |

| any surface. |

|

TECHNICAL TIPS

GRINDING

Always use side/top mount handle for control. Move the grinder back and forth in sweeping strokes. Too much pressure, the wrong angle or improper motion may cause burning. Be aware of your material’s reaction to the grinding disc. Some materials may throw excessive sparks; some materials may conduct extreme heat from the point of contact.

Avoid unnecessary risks by staying alert and attentive at all times.

CUTTING

Always use side/top mount handle for control. Make sure your cutting disc is rated for AT LEAST 11,000 RPM. Pull trigger switch and carefully apply cutting blade edge to material to be cut. As with grinding, too much pressure, the wrong angle or improper motion may cause burning. Be aware of your material’s reaction to the cutting disc. Some materials may throw excessive sparks; some materials may conduct extreme heat from the point of contact. Avoid unnecessary risks by staying alert and attentive at all times.

WARNING: To reduce the risk of injury, keep the cord away from the path of the grinder. Otherwise the cord may be caught by the disc; this may sever the cord and expose live wires or make the gear box electrically “live.”

4