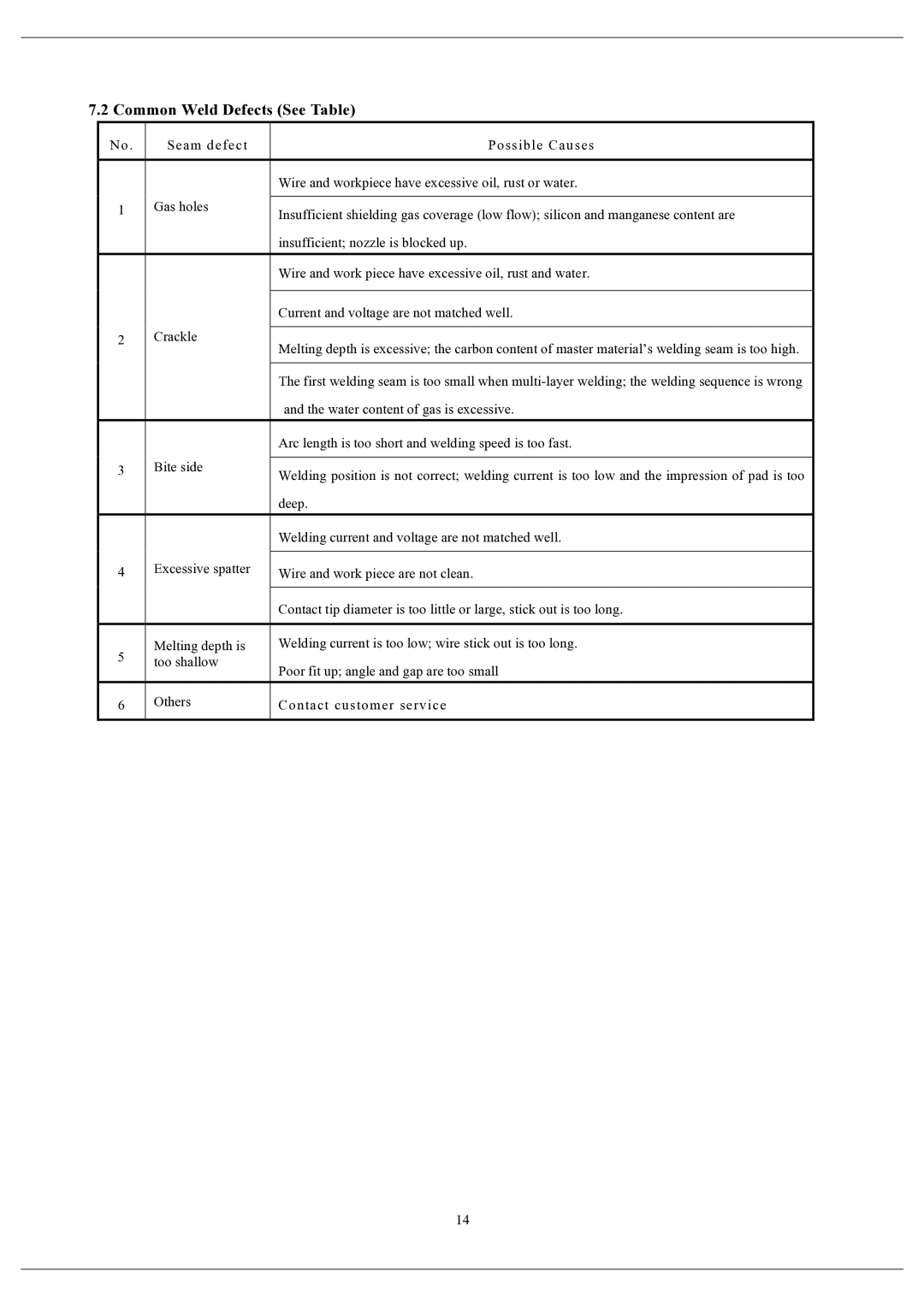

7.2 Common Weld Defects (See Table)

No. | Seam defect | Possible Causes | |

|

|

| |

|

| Wire and workpiece have excessive oil, rust or water. | |

1 | Gas holes |

| |

Insufficient shielding gas coverage (low flow); silicon and manganese content are | |||

|

| ||

|

| insufficient; nozzle is blocked up. | |

|

|

| |

|

| Wire and work piece have excessive oil, rust and water. | |

|

|

| |

|

| Current and voltage are not matched well. | |

2 | Crackle |

| |

Melting depth is excessive; the carbon content of master material’s welding seam is too high. | |||

|

| ||

|

|

| |

|

| The first welding seam is too small when | |

|

| and the water content of gas is excessive. | |

|

|

| |

|

| Arc length is too short and welding speed is too fast. | |

3 | Bite side |

| |

Welding position is not correct; welding current is too low and the impression of pad is too | |||

|

| ||

|

| deep. | |

|

|

| |

|

| Welding current and voltage are not matched well. | |

4 | Excessive spatter |

| |

Wire and work piece are not clean. | |||

|

|

| |

|

| Contact tip diameter is too little or large, stick out is too long. | |

|

|

| |

5 | Melting depth is | Welding current is too low; wire stick out is too long. | |

too shallow | Poor fit up; angle and gap are too small | ||

| |||

|

| ||

|

|

| |

6 | Others | Contact customer service | |

|

|

|

14