*Regularly remove the spatter from the inside of the nozzle to prevent a short circuit. Use nozzle gel to minimize spatter buildup in the nozzle.

*Use appropriate wire listed on the parameter chart. Do not use rusty or dirty wire.

*Clean the dust and metal filings from the liner with compressed air. The dust is accumulated by friction between wire and liner, drive rolls and magnetic attraction of the wire to metal debris. If wire feeding is uneven this may be the problem.

*Do not over tighten the drive roll idler are, it will increase resistance, friction and possible deform the wire.

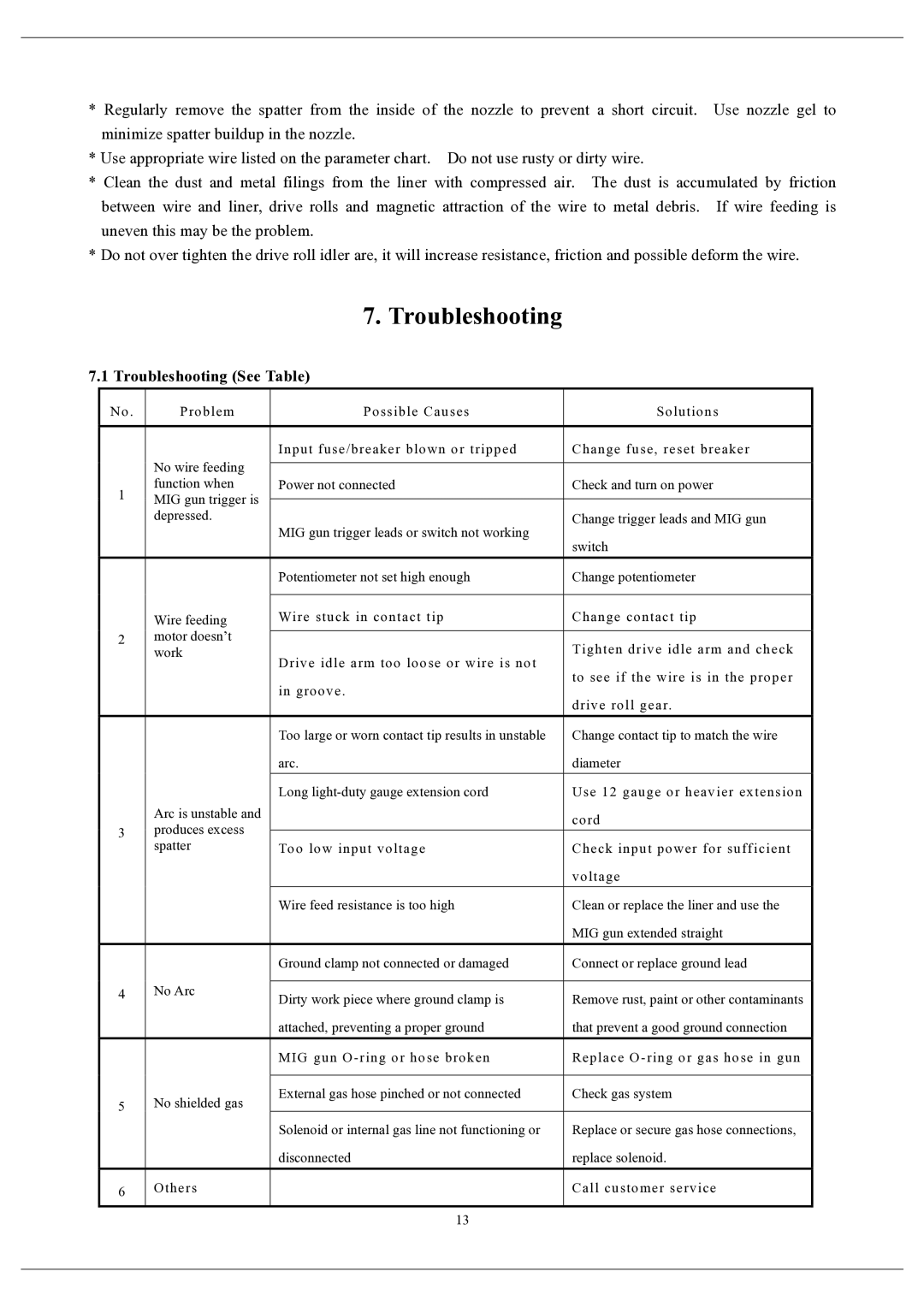

7. Troubleshooting

7.1 Troubleshooting (See Table)

No. | Problem | Possible Causes | Solutions | |

|

|

|

| |

|

| Input fuse/breaker blown or tripped | Change fuse, reset breaker | |

| No wire feeding |

|

| |

|

|

| ||

1 | function when | Power not connected | Check and turn on power | |

MIG gun trigger is |

|

| ||

|

|

| ||

| depressed. | MIG gun trigger leads or switch not working | Change trigger leads and MIG gun | |

|

| switch | ||

|

|

| ||

|

|

|

| |

|

| Potentiometer not set high enough | Change potentiometer | |

|

|

|

| |

| Wire feeding | Wire stuck in contact tip | Change contact tip | |

2 | motor doesn’t |

|

| |

| Tighten drive idle arm and check | |||

| work | Drive idle arm too loose or wire is not | ||

|

| to see if the wire is in the proper | ||

|

| in groove. | ||

|

| drive roll gear. | ||

|

|

| ||

|

|

|

| |

|

| Too large or worn contact tip results in unstable | Change contact tip to match the wire | |

|

| arc. | diameter | |

|

|

|

| |

|

| Long | Use 12 gauge or heavier extension | |

| Arc is unstable and |

| cord | |

3 | produces excess |

| ||

|

| |||

|

| |||

| spatter | Too low input voltage | Check input power for sufficient | |

|

|

| voltage | |

|

|

|

| |

|

| Wire feed resistance is too high | Clean or replace the liner and use the | |

|

|

| MIG gun extended straight | |

|

|

|

| |

|

| Ground clamp not connected or damaged | Connect or replace ground lead | |

4 | No Arc |

|

| |

Dirty work piece where ground clamp is | Remove rust, paint or other contaminants | |||

|

| |||

|

| attached, preventing a proper ground | that prevent a good ground connection | |

|

|

|

| |

|

| MIG gun | Replace | |

|

|

|

| |

5 | No shielded gas | External gas hose pinched or not connected | Check gas system | |

|

| |||

|

| Solenoid or internal gas line not functioning or | Replace or secure gas hose connections, | |

|

| disconnected | replace solenoid. | |

|

|

|

| |

6 | Others |

| Call customer service | |

|

|

|

| |

|

| 13 |

|