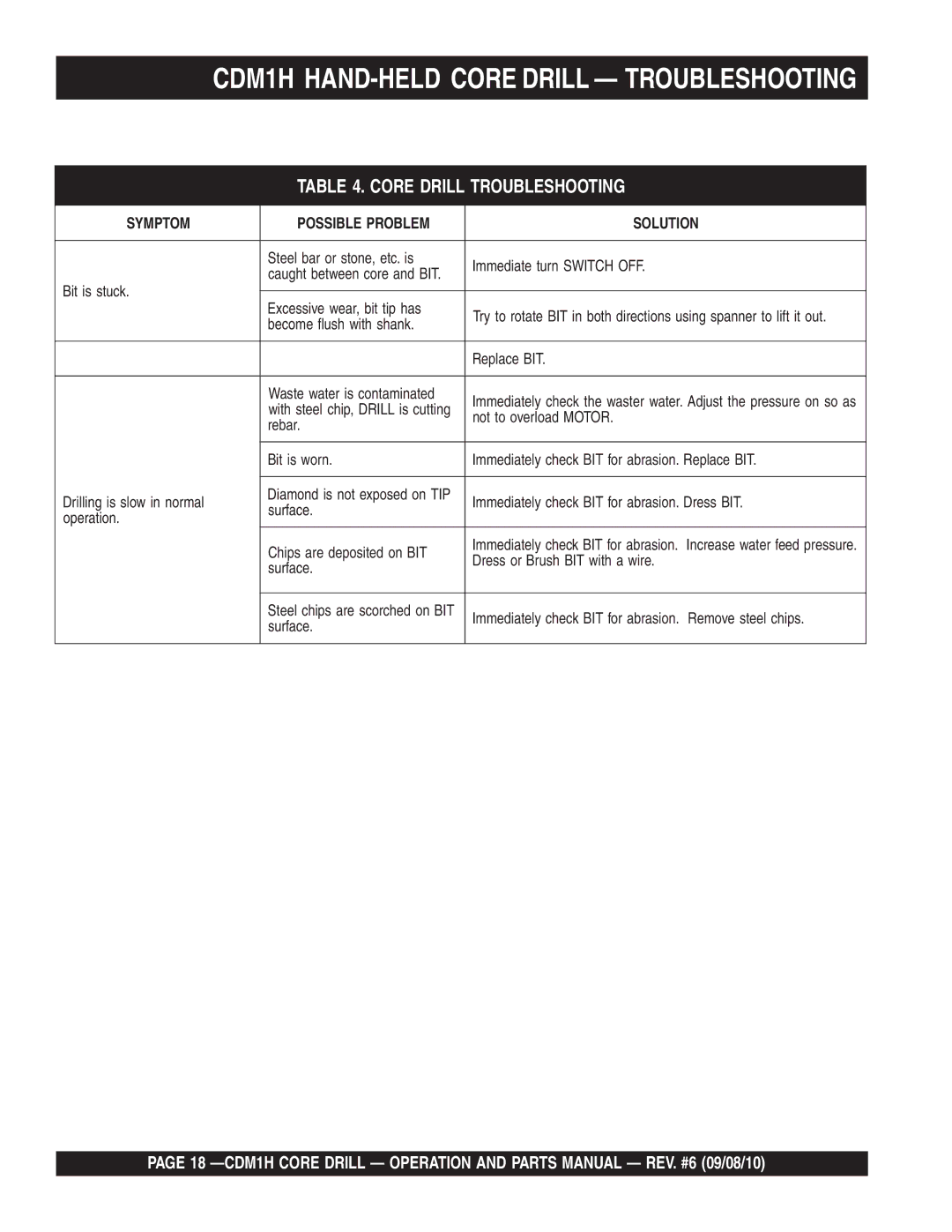

CDM1H HAND-HELD CORE DRILL — TROUBLESHOOTING

TABLE 4. CORE DRILL TROUBLESHOOTING

SYMPTOM | POSSIBLE PROBLEM | SOLUTION | |

|

|

| |

| Steel bar or stone, etc. is | Immediate turn SWITCH OFF. | |

| caught between core and BIT. | ||

Bit is stuck. |

| ||

|

| ||

Excessive wear, bit tip has | Try to rotate BIT in both directions using spanner to lift it out. | ||

| |||

| become flush with shank. | ||

|

| ||

|

|

| |

|

| Replace BIT. | |

|

|

| |

| Waste water is contaminated | Immediately check the waster water. Adjust the pressure on so as | |

| with steel chip, DRILL is cutting | ||

| not to overload MOTOR. | ||

| rebar. | ||

|

| ||

|

|

| |

| Bit is worn. | Immediately check BIT for abrasion. Replace BIT. | |

|

|

| |

Drilling is slow in normal | Diamond is not exposed on TIP | Immediately check BIT for abrasion. Dress BIT. | |

surface. | |||

operation. |

| ||

|

| ||

| Chips are deposited on BIT | Immediately check BIT for abrasion. Increase water feed pressure. | |

| Dress or Brush BIT with a wire. | ||

| surface. | ||

|

| ||

|

|

| |

| Steel chips are scorched on BIT | Immediately check BIT for abrasion. Remove steel chips. | |

| surface. | ||

|

| ||

|

|

|

PAGE 18