4. ORP Electrode Calibration

All ORP electrodes are designed to ensure linearity during their lifespan. The following sections define proper electrode operation.

4.1 Offset (STD)

Electrode offsets occur due to:

•Clogged reference junction

•Aged or contaminated reference solution/wire

Offsets are easily checked in pH 7 buffer saturated with quinhydrone @ 25 °C; since the theoretical output is +87 mV. Any deviation from +87 mV is the ORP electrode offset (i.e. +90 mV). Quinhydrone is the oxidizer measured by the ORP electrode and is required for calibration. To guarantee buffer saturation, mix 1/8g quinhydrone per 50 mL of pH buffer.

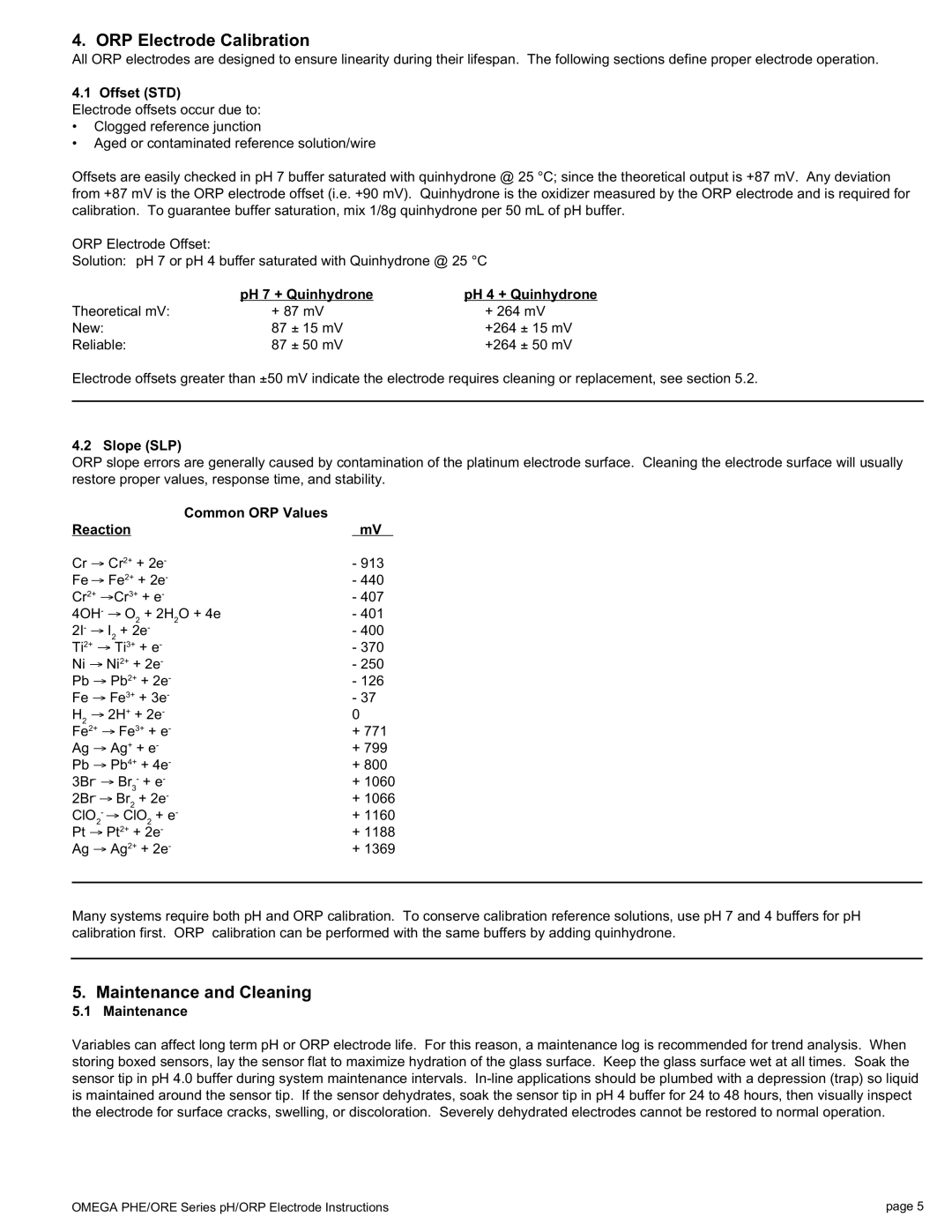

ORP Electrode Offset:

Solution: pH 7 or pH 4 buffer saturated with Quinhydrone @ 25 °C

| pH 7 + Quinhydrone | pH 4 + Quinhydrone |

Theoretical mV: | + 87 mV | + 264 mV |

New: | 87 ± 15 mV | +264 ± 15 mV |

Reliable: | 87 ± 50 mV | +264 ± 50 mV |

Electrode offsets greater than ±50 mV indicate the electrode requires cleaning or replacement, see section 5.2.

4.2 Slope (SLP)

ORP slope errors are generally caused by contamination of the platinum electrode surface. Cleaning the electrode surface will usually restore proper values, response time, and stability.

| Common ORP Values |

|

Reaction |

| mV |

Cr → Cr2+ + 2e- | - 913 | |

Fe → Fe2+ + 2e- | - 440 | |

Cr2+ →Cr3+ + e- | - 407 | |

4OH- → O2 + 2H2O + 4e | - 401 | |

2I- → I2 + 2e- | - 400 | |

Ti2+ → Ti3+ + e- | - 370 | |

Ni → Ni2+ + 2e- | - 250 | |

Pb → Pb2+ + 2e- | - 126 | |

Fe → Fe3+ + 3e- | - 37 | |

H → 2H+ | + 2e- | 0 |

2 |

|

|

Fe2+ → Fe3+ + e- | + 771 | |

Ag → Ag+ + e- | + 799 | |

Pb → Pb4+ + 4e- | + 800 | |

3Br- → Br3- + e- | + 1060 | |

2Br- → Br2 + 2e- | + 1066 | |

ClO - → ClO + e- | + 1160 | |

2 | 2 |

|

Pt → Pt2+ + 2e- | + 1188 | |

Ag → Ag2+ + 2e- | + 1369 | |

|

|

|

Many systems require both pH and ORP calibration. To conserve calibration reference solutions, use pH 7 and 4 buffers for pH calibration first. ORP calibration can be performed with the same buffers by adding quinhydrone.

5. Maintenance and Cleaning

5.1 Maintenance

Variables can affect long term pH or ORP electrode life. For this reason, a maintenance log is recommended for trend analysis. When storing boxed sensors, lay the sensor flat to maximize hydration of the glass surface. Keep the glass surface wet at all times. Soak the sensor tip in pH 4.0 buffer during system maintenance intervals.

OMEGA PHE/ORE Series pH/ORP Electrode Instructions | page 5 |