Notes | General Description | |

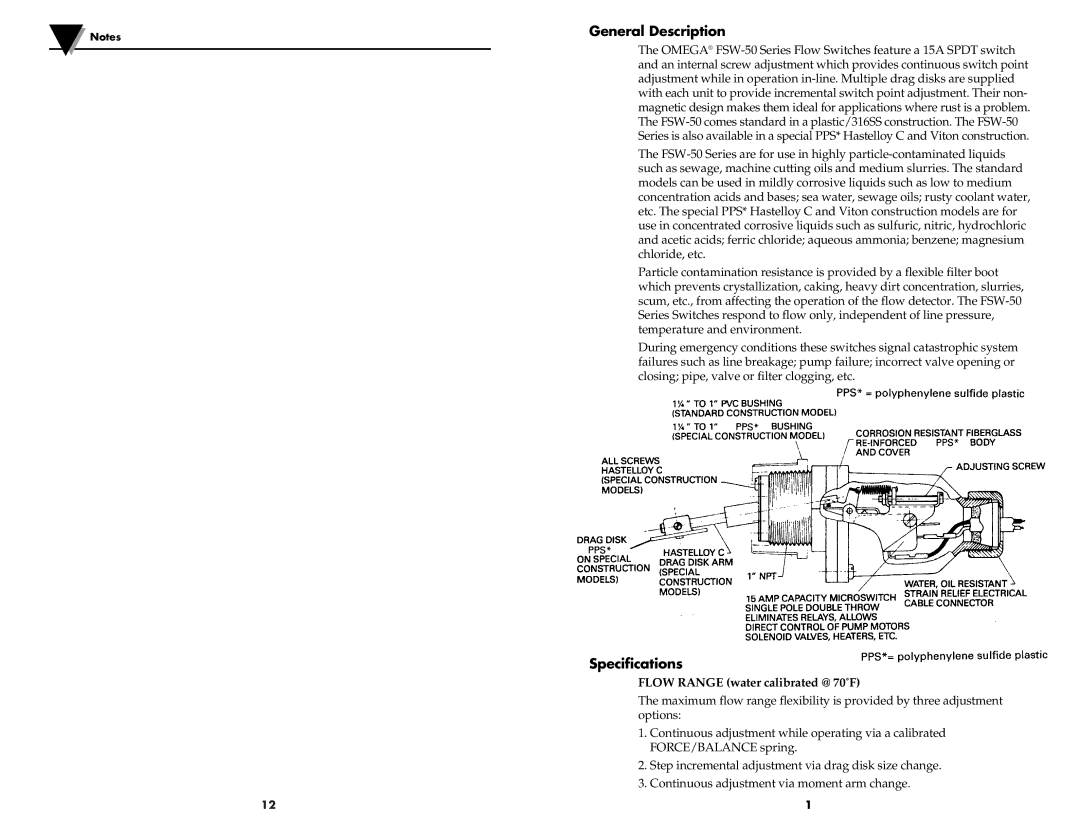

The OMEGA® | ||

| ||

| ||

| and an internal screw adjustment which provides continuous switch point | |

| adjustment while in operation | |

| with each unit to provide incremental switch point adjustment. Their non- | |

| magnetic design makes them ideal for applications where rust is a problem. | |

| The | |

| Series is also available in a special PPS* Hastelloy C and Viton construction. | |

| The | |

| such as sewage, machine cutting oils and medium slurries. The standard | |

| models can be used in mildly corrosive liquids such as low to medium | |

| concentration acids and bases; sea water, sewage oils; rusty coolant water, | |

| etc. The special PPS* Hastelloy C and Viton construction models are for | |

| use in concentrated corrosive liquids such as sulfuric, nitric, hydrochloric | |

| and acetic acids; ferric chloride; aqueous ammonia; benzene; magnesium | |

| chloride, etc. | |

| Particle contamination resistance is provided by a flexible filter boot | |

| which prevents crystallization, caking, heavy dirt concentration, slurries, | |

| scum, etc., from affecting the operation of the flow detector. The | |

| Series Switches respond to flow only, independent of line pressure, | |

| temperature and environment. | |

| During emergency conditions these switches signal catastrophic system | |

| failures such as line breakage; pump failure; incorrect valve opening or | |

| closing; pipe, valve or filter clogging, etc. |

Specifications

FLOW RANGE (water calibrated @ 70˚F)

The maximum flow range flexibility is provided by three adjustment options:

1. Continuous adjustment while operating via a calibrated FORCE/BALANCE spring.

2. Step incremental adjustment via drag disk size change.

3. Continuous adjustment via moment arm change.

12 | 1 |