4.2 Wind Sensor Installation

Choose the mounting location for the wind sensor and temperature sensor unit which is free from obstructions. Use extreme care to prevent contact with electrical power lines while erecting the unit. A typical installation will position the wind sensor approximately 10 meters above the highest obstacle within a 300 meter radius of the mounting locations. Position the

4.3 Transmitter Installation

Mount the transmitter assembly in a covered location where it can be conveniently connected to its exterior wind sensor. The

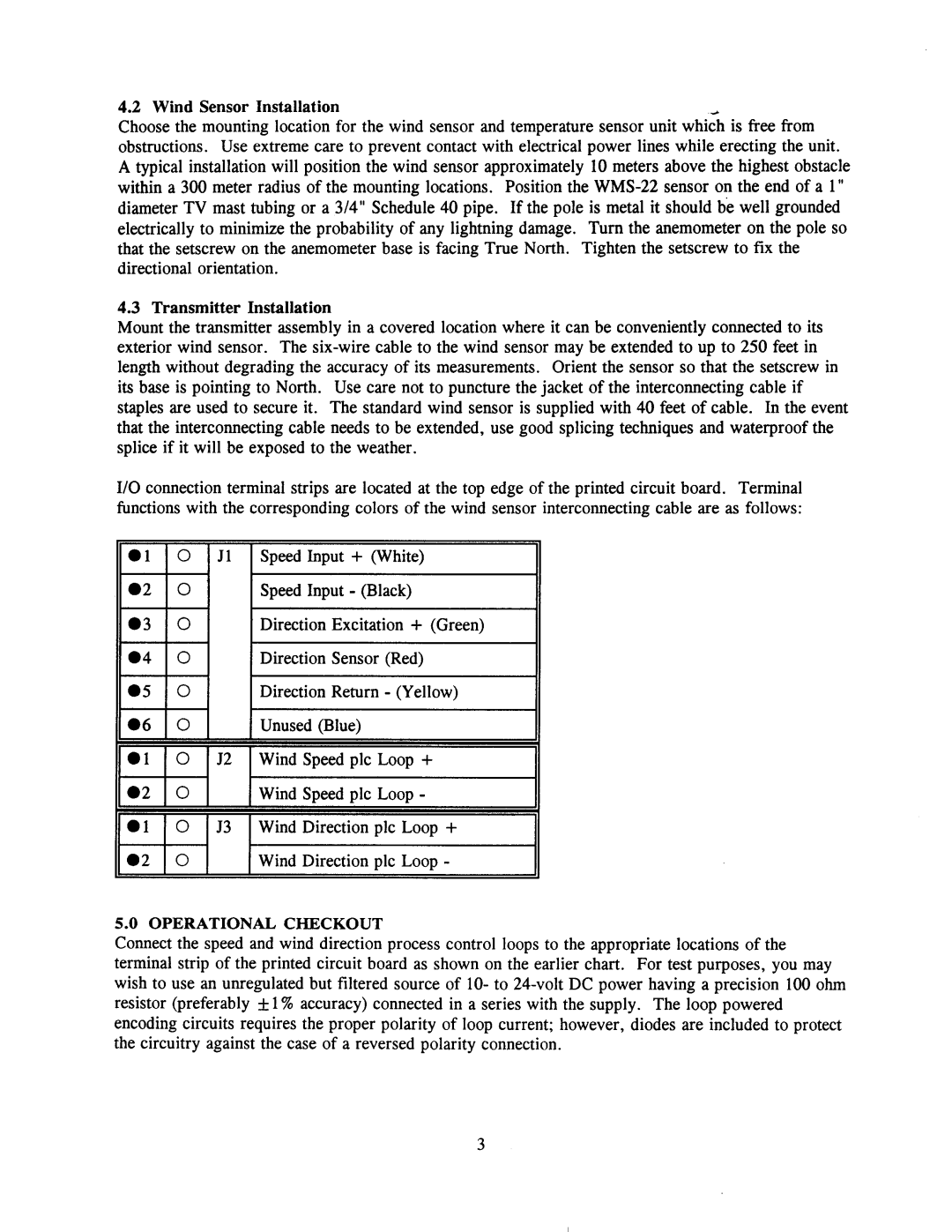

I/O connection terminal strips are located at the top edge of the printed circuit board. Terminal functions with the corresponding colors of the wind sensor interconnecting cable are as follows:

0 1 1 0 1 Jl 1 Speed Input + (White)

•2 lo l I Speed Input - (Black)

•5 lo l I Direction Return - (Yellow)

06 0 | Unused (Blue) |

01 0 52 Wind Speed plc Loop +

a2 0Wind Sneed ~lc LOOD -

01 0 53 Wind Direction plc Loop +

a2 0Wind Direction plc Loop -

5.0 OPERATIONAL CHECKOUT

Connect the speed and wind direction process control loops to the appropriate locations of the terminal strip of the printed circuit board as shown on the earlier chart. For test purposes, you may wish to use an unregulated but filtered source of lo- to