SPECIFICATIONS

Step One

Specifications:

Accuracy: | ± 5 mm in water |

Repeatability: | ± 2 mm in water |

Extreme orientation: | ±20° from vertical |

Specific Gravity Range: 0.8 - 1.2 | |

Reed type: | Dry contact, SPST |

Reed rating: | 120 VAC, 120 VDC @ 50 VA |

| (CE: 30 Vrms and 42.2 Vpeak or 60 Vdc) |

Reed output: | NO or NC |

Temperature range: | F: |

| C: |

Pressure: | 10 psi (0.7 bar) max. |

Sensor material: | Polypropylene (PP) or |

| Polyvinylidene Fluoride (PVDF) |

Mounting threads: | 1/8" NPT (1/8” BSP) |

Cable type: | 2 ft. (61 cm), |

CE compliance: | EN |

| EN 55011 emission |

Part Number Information:

Part # | Material | Thread |

PP | 1/8" NPT | |

PVDF | 1/8" NPT |

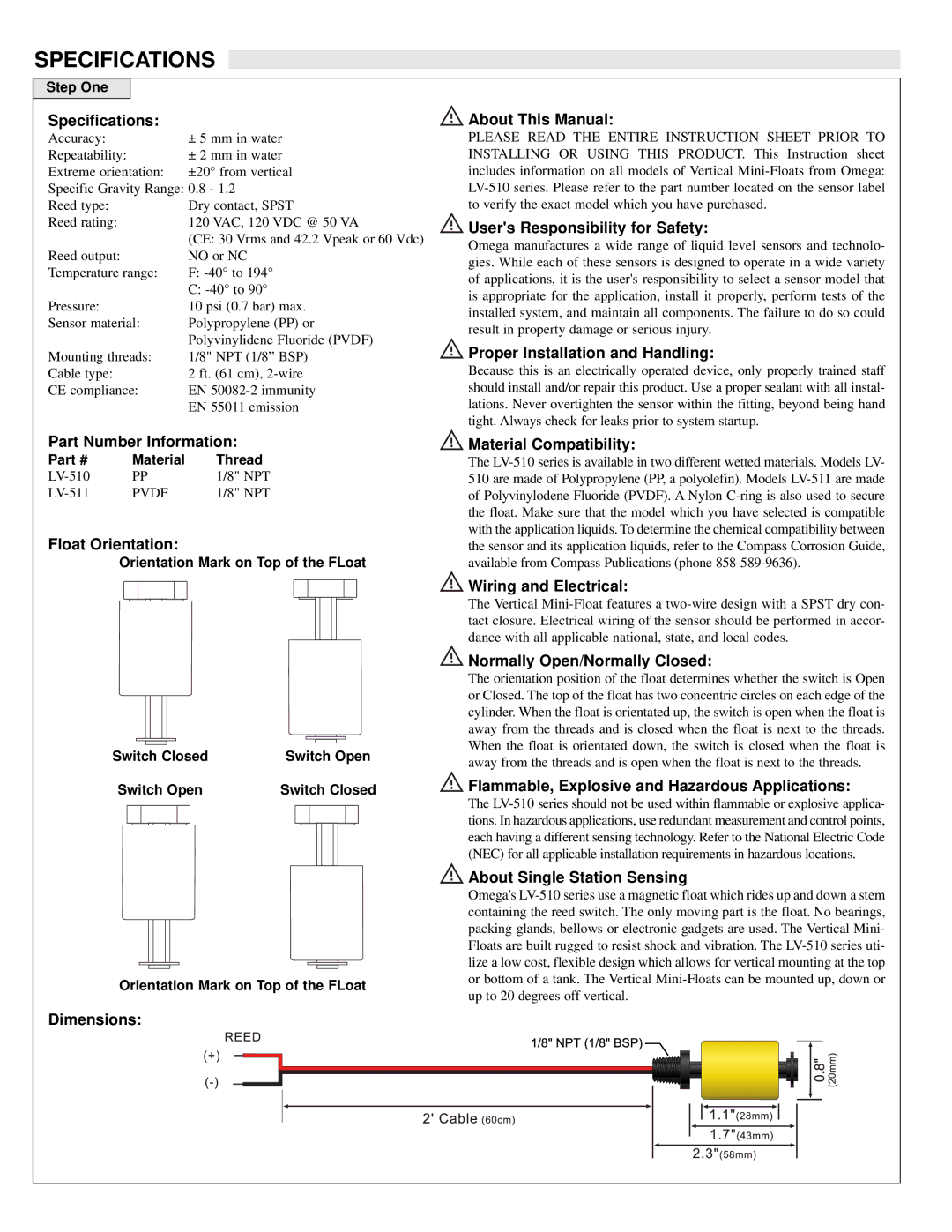

Float Orientation:

Orientation Mark on Top of the FLoat

Switch Closed | Switch Open | ||||||||||||||||||

Switch Open | Switch Closed | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Orientation Mark on Top of the FLoat

About This Manual:

About This Manual:

PLEASE READ THE ENTIRE INSTRUCTION SHEET PRIOR TO INSTALLING OR USING THIS PRODUCT. This Instruction sheet includes information on all models of Vertical

User's Responsibility for Safety:

User's Responsibility for Safety:

Omega manufactures a wide range of liquid level sensors and technolo- gies. While each of these sensors is designed to operate in a wide variety of applications, it is the user's responsibility to select a sensor model that is appropriate for the application, install it properly, perform tests of the installed system, and maintain all components. The failure to do so could result in property damage or serious injury.

Proper Installation and Handling:

Proper Installation and Handling:

Because this is an electrically operated device, only properly trained staff should install and/or repair this product. Use a proper sealant with all instal- lations. Never overtighten the sensor within the fitting, beyond being hand tight. Always check for leaks prior to system startup.

Material Compatibility:

Material Compatibility:

The

Wiring and Electrical:

Wiring and Electrical:

The Vertical

Normally Open/Normally Closed:

Normally Open/Normally Closed:

The orientation position of the float determines whether the switch is Open or Closed. The top of the float has two concentric circles on each edge of the cylinder. When the float is orientated up, the switch is open when the float is away from the threads and is closed when the float is next to the threads. When the float is orientated down, the switch is closed when the float is away from the threads and is open when the float is next to the threads.

Flammable, Explosive and Hazardous Applications:

Flammable, Explosive and Hazardous Applications:

The

About Single Station Sensing

About Single Station Sensing

Omega's