4 | Omnitron Systems Technology, Inc. |

CONTROLS AND INDICATORS

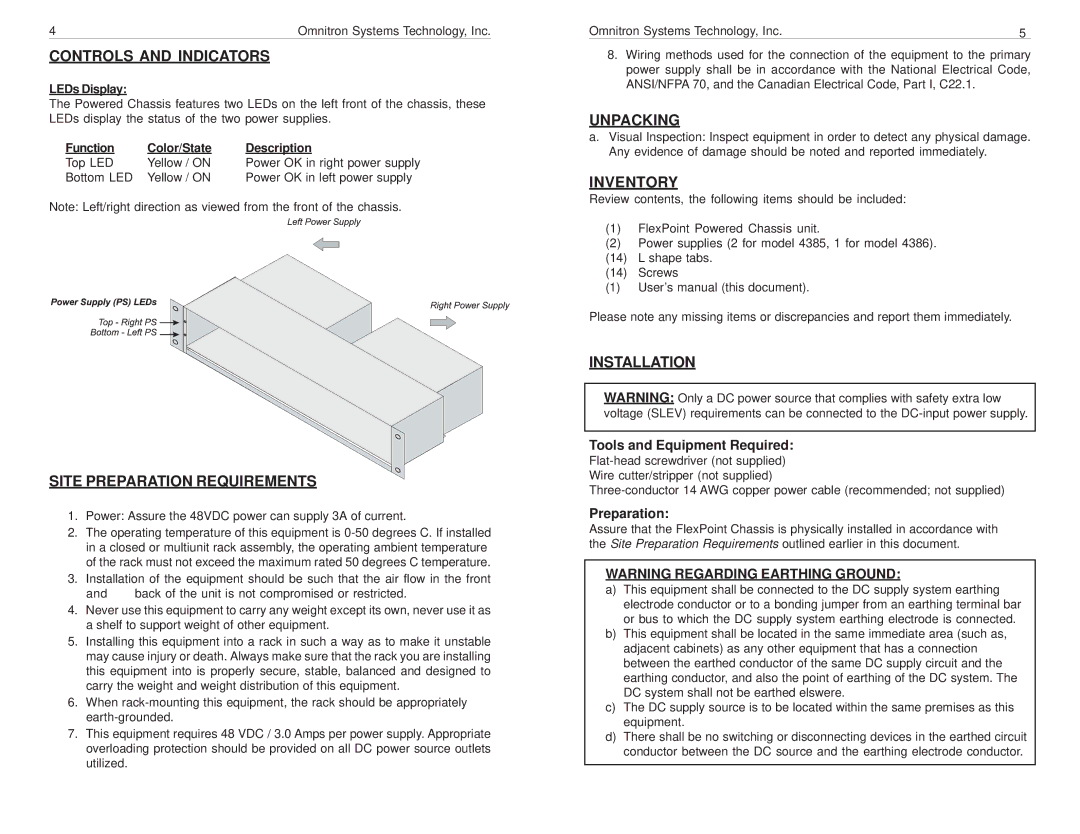

LEDs Display:

The Powered Chassis features two LEDs on the left front of the chassis, these LEDs display the status of the two power supplies.

Function | Color/State | Description |

Top LED | Yellow / ON | Power OK in right power supply |

Bottom LED | Yellow / ON | Power OK in left power supply |

Note: Left/right direction as viewed from the front of the chassis.

SITE PREPARATION REQUIREMENTS

1.Power: Assure the 48VDC power can supply 3A of current.

2.The operating temperature of this equipment is

3.Installation of the equipment should be such that the air flow in the front

and | back of the unit is not compromised or restricted. |

4.Never use this equipment to carry any weight except its own, never use it as a shelf to support weight of other equipment.

5.Installing this equipment into a rack in such a way as to make it unstable may cause injury or death. Always make sure that the rack you are installing this equipment into is properly secure, stable, balanced and designed to carry the weight and weight distribution of this equipment.

6.When

7.This equipment requires 48 VDC / 3.0 Amps per power supply. Appropriate overloading protection should be provided on all DC power source outlets utilized.

Omnitron Systems Technology, Inc. | 5 |

8.Wiring methods used for the connection of the equipment to the primary power supply shall be in accordance with the National Electrical Code, ANSI/NFPA 70, and the Canadian Electrical Code, Part I, C22.1.

UNPACKING

a.Visual Inspection: Inspect equipment in order to detect any physical damage. Any evidence of damage should be noted and reported immediately.

INVENTORY

Review contents, the following items should be included:

(1)FlexPoint Powered Chassis unit.

(2)Power supplies (2 for model 4385, 1 for model 4386).

(14) L shape tabs.

(14) Screws

(1)User’s manual (this document).

Please note any missing items or discrepancies and report them immediately.

INSTALLATION

WARNING: Only a DC power source that complies with safety extra low voltage (SLEV) requirements can be connected to the

Tools and Equipment Required:

Preparation:

Assure that the FlexPoint Chassis is physically installed in accordance with the Site Preparation Requirements outlined earlier in this document.

WARNING REGARDING EARTHING GROUND:

a)This equipment shall be connected to the DC supply system earthing electrode conductor or to a bonding jumper from an earthing terminal bar or bus to which the DC supply system earthing electrode is connected.

b)This equipment shall be located in the same immediate area (such as, adjacent cabinets) as any other equipment that has a connection between the earthed conductor of the same DC supply circuit and the earthing conductor, and also the point of earthing of the DC system. The DC system shall not be earthed elswere.

c)The DC supply source is to be located within the same premises as this equipment.

d)There shall be no switching or disconnecting devices in the earthed circuit conductor between the DC source and the earthing electrode conductor.