RUN-TIME ACTIVITY & ERROR MONITORING

During normal operation the fiber optic and copper ready LEDs provide continuous diagnostic information. These LEDs detect and display token ring activity.

The insert status LED informs the user of the insert status of the fiber optic and copper media. This LED lights green when both the active signaling fiber optic and copper devices have successfully reached insertion.

The insert status LED flashes when the OmniHawk™ has received phan- tom current on its copper side but has not yet achieved insertion on its fiber optic side, or conversely, when the unit has received the fiber optic key on its fiber side but has not yet sensed a phantom current echoer on its copper side.

When the OmniHawk™ connects to passive devices, the insert status LED will always be off.

UNPACKING

a.Visual Inspection - before unpacking, a visual inspection should be con- ducted in order to detect any physical damage to the equipment. Any evidence of damage should be noted and reported immediately.

b.Unpacking - place shipping container on a flat surface, cut straps or tape, open top. Take out each item carefully and place securely on a clean flat surface. Return all packing material into container (foam, boxes etc.), close and store away for future

c.Inspection - Inspect each item for any apparent damage, any evidence of damage should be noted and reported immediately.

d.Content - Review the content; the following items should be included:

•OmniHawk™ module (1)

•power supply module

•User’s Manual (the document you are now reading)

Please note any missing items or discrepancies and report them imme- diately.

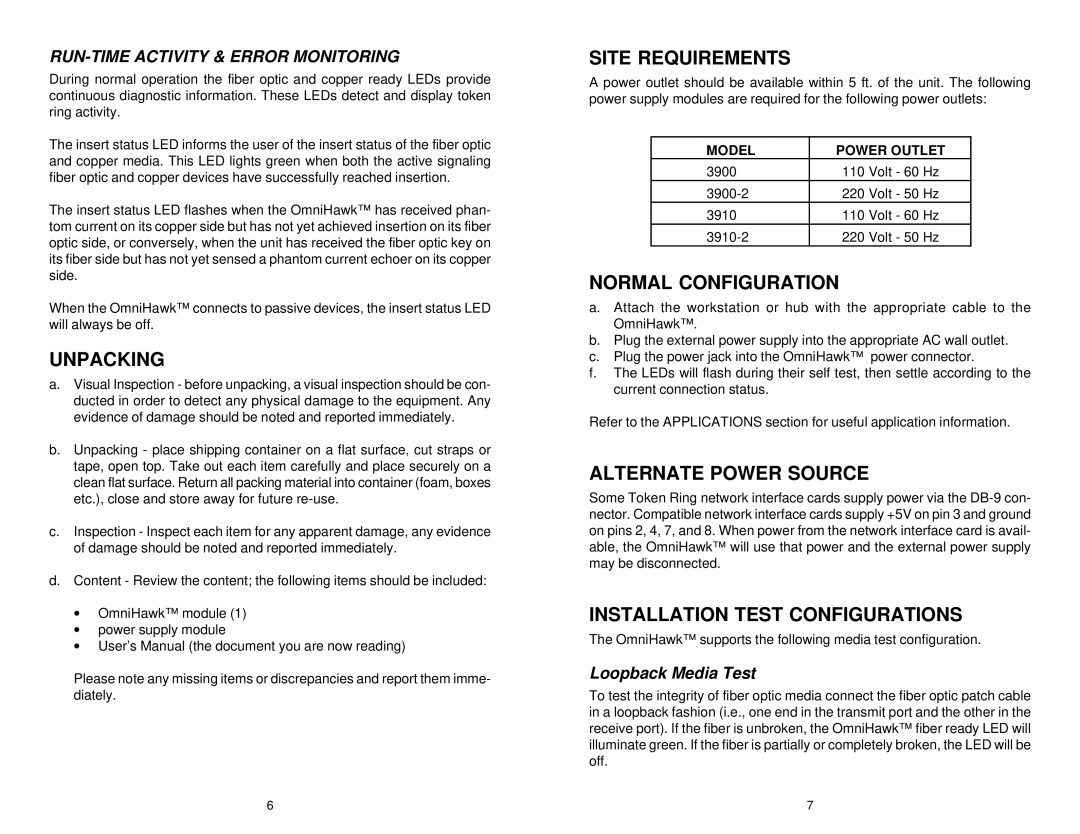

SITE REQUIREMENTS

A power outlet should be available within 5 ft. of the unit. The following power supply modules are required for the following power outlets:

MODEL | POWER OUTLET |

3900 | 110 Volt - 60 Hz |

220 Volt - 50 Hz | |

3910 | 110 Volt - 60 Hz |

220 Volt - 50 Hz |

NORMAL CONFIGURATION

a.Attach the workstation or hub with the appropriate cable to the OmniHawk™.

b.Plug the external power supply into the appropriate AC wall outlet.

c.Plug the power jack into the OmniHawk™ power connector.

f.The LEDs will flash during their self test, then settle according to the current connection status.

Refer to the APPLICATIONS section for useful application information.

ALTERNATE POWER SOURCE

Some Token Ring network interface cards supply power via the

INSTALLATION TEST CONFIGURATIONS

The OmniHawk™ supports the following media test configuration.

Loopback Media Test

To test the integrity of fiber optic media connect the fiber optic patch cable in a loopback fashion (i.e., one end in the transmit port and the other in the receive port). If the fiber is unbroken, the OmniHawk™ fiber ready LED will illuminate green. If the fiber is partially or completely broken, the LED will be off.

6 | 7 |