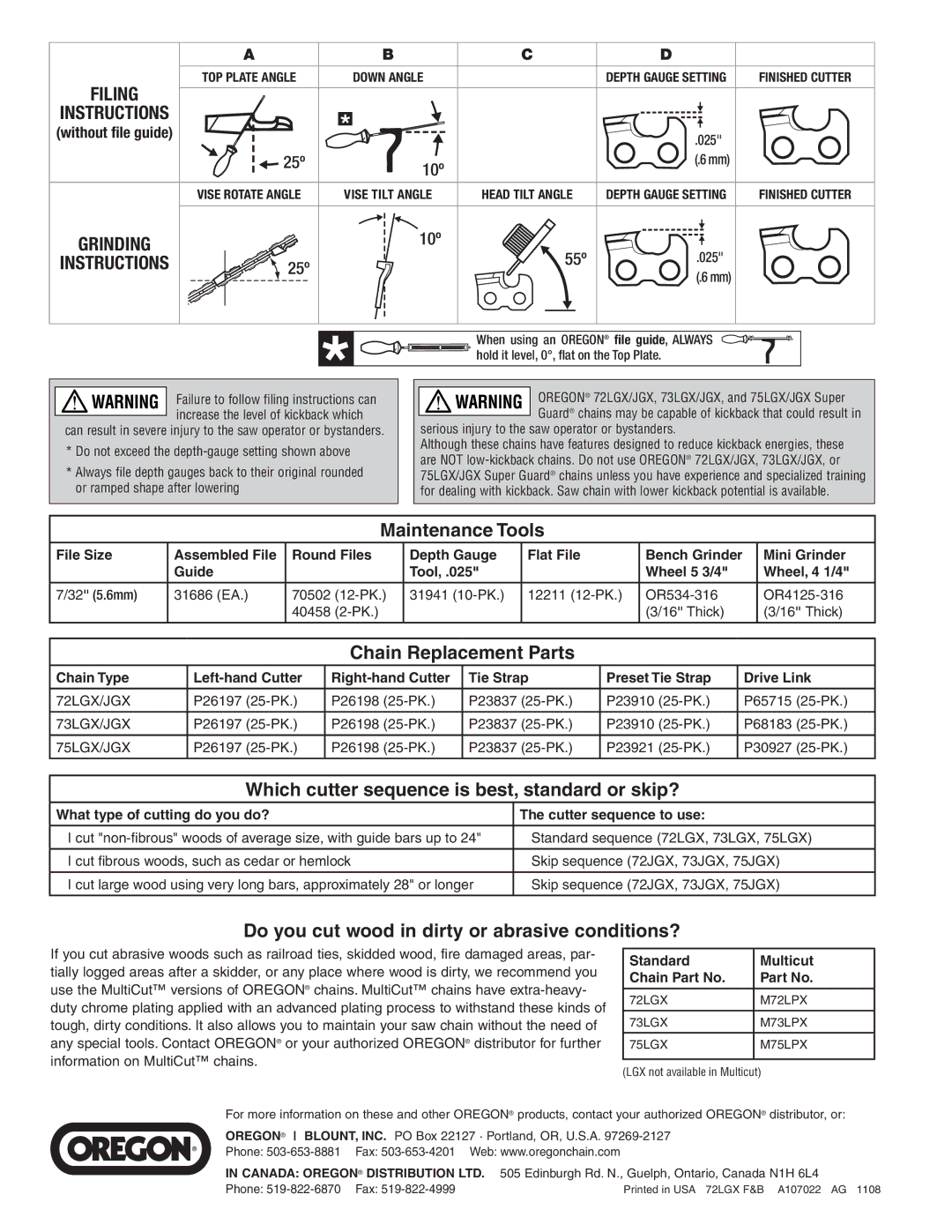

75LGX, 73LGX, 72LGX specifications

Oregon 72LGX, 73LGX, and 75LGX are part of Oregon's advanced line of laser-guided chainsaws, designed to bring precision, power, and efficiency to tree care and forestry work. These chainsaws are specifically engineered for professional arborists, landscapers, and forestry workers who need reliable equipment that enhances their productivity while ensuring safety and accuracy.One of the standout features of the Oregon 72LGX, 73LGX, and 75LGX models is their innovative laser guide system. This technology allows users to make straight cuts with remarkable precision, significantly reducing the chances of making mistakes that could result in injury or damage to surrounding foliage. The laser guide projects a visible line on the material being cut, providing a clear reference point that helps users align their cuts accurately.

The chainsaw’s high-performance chain design is another significant characteristic. Both the 72LGX and 73LGX feature a 3/8-inch pitch, 0.050-inch gauge chain that excels in cutting efficiency and speed. The 75LGX model takes it a step further with a more specialized design for heavier-duty applications, ensuring smoother operation and longer-lasting performance even when faced with demanding conditions.

Equipped with a robust motor, these chainsaws deliver high power output, enabling them to tackle a wide array of tree cutting tasks. The ergonomic design of the grips and controls provides comfort during extended use, reducing fatigue and improving operator control. Safety features such as low kickback chains and built-in chain brakes contribute to user safety, allowing professionals to focus on their work confidently.

Additionally, these chainsaws incorporate advanced materials that enhance durability. The construction of the guide bars and chains ensures a longer lifespan, which is especially crucial for professionals who rely on their equipment daily. Maintenance becomes easier with the user-friendly designs, allowing for quick chain replacement and adjustments.

Overall, the Oregon 72LGX, 73LGX, and 75LGX models represent a blend of cutting-edge technology and user-centric design, making them indispensable tools for professionals in the arboriculture and forestry industries. Their focus on precision, safety, and durability sets a high standard for performance in power tools, proving essential for those who rely on their equipment for excellence in tree care.