Lid/Door Safety Switch specifications

The Paragon Lid/Door Safety Switch is an essential component designed to enhance safety and reliability in various applications where lid or door operation is critical. These switches are commonly used in industrial machinery, appliances, and automated systems to prevent accidental operation and ensure user safety.One of the main features of the Paragon Lid/Door Safety Switch is its robust design. Constructed from durable materials, it is engineered to withstand harsh environments and resist wear and tear over time. This reliability is crucial in preventing operational failures that could lead to accidents or equipment damage.

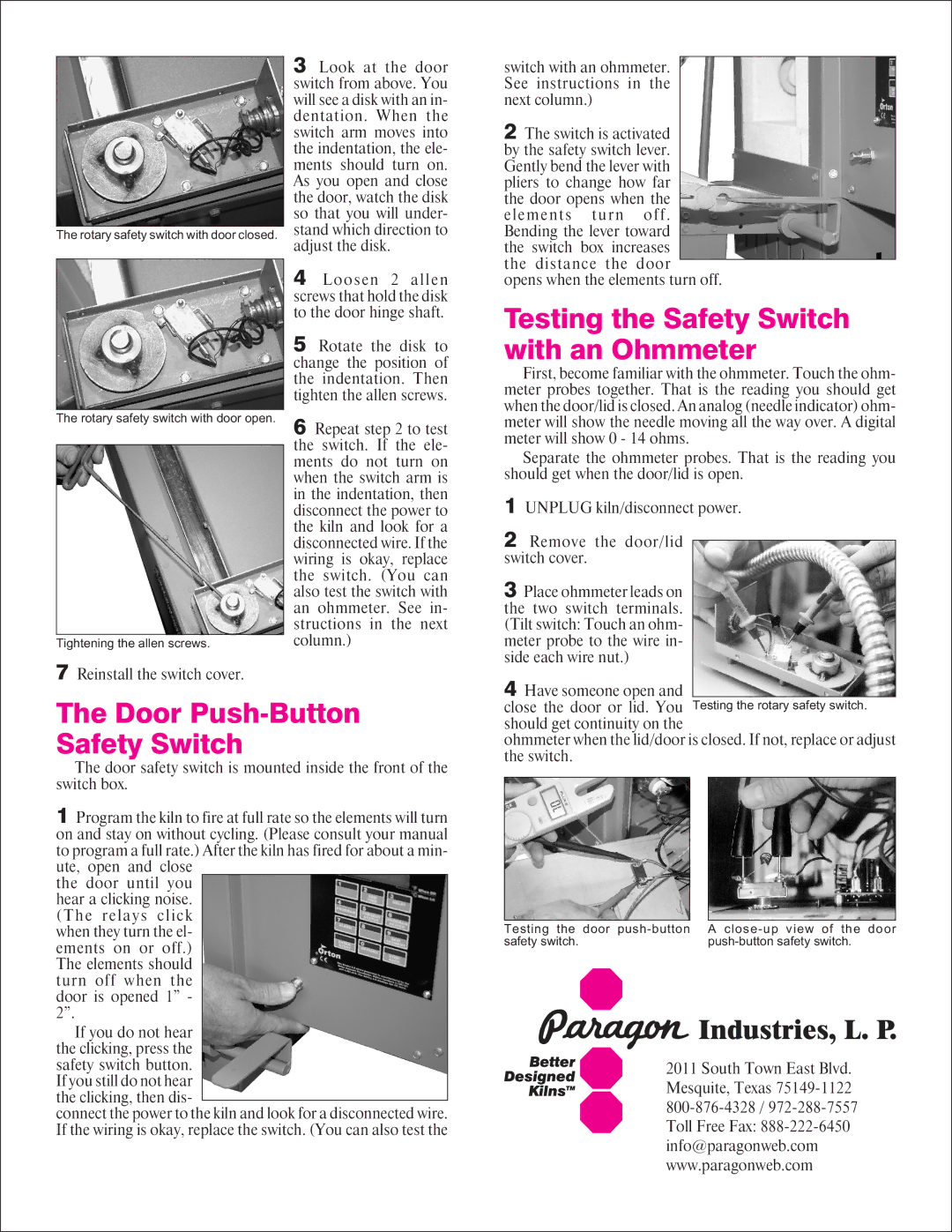

The switch employs a versatile actuator mechanism that can be tailored to fit different lid and door types. This adaptability makes it suitable for a wide range of applications, from industrial equipment to household appliances. The actuator’s smooth operation ensures that the switch can easily detect when a lid or door is opened or closed, providing a reliable signal to the control system.

Incorporating advanced technological features, the Paragon Lid/Door Safety Switch may include integrated safety circuits that comply with global safety standards. These circuits help mitigate risks and ensure that the system shuts down or remains inactive whenever the lid or door is ajar, preventing unintended operations.

Another notable characteristic of the Paragon switch is its ease of installation. The design typically includes user-friendly mounting options, which streamline setup and minimize downtime during installation. Furthermore, the switches can be integrated seamlessly into existing systems without requiring extensive modifications.

The Paragon Lid/Door Safety Switch also features a range of electrical ratings, allowing it to be used with different power configurations. This flexibility enables users to choose the appropriate switch for their specific application, ensuring optimal performance.

Additionally, operational feedback is often provided through visual or auditory signals, alerting users when the door or lid is not properly secured. This added layer of safety is invaluable in environments where machine operation without proper safeguards can result in serious injuries.

In summary, the Paragon Lid/Door Safety Switch stands out due to its durability, adaptability, and adherence to safety standards. With advanced technology and user-friendly design, it is an excellent choice for anyone seeking to enhance safety in equipment and machinery operation.