![]()

![]()

![]()

![]()

![]()

![]() Thermific®

Thermific®

1.0 INTRODUCTION

Direct vent (ANSI Z21.13) is a closed system method of ducting the combustion air directly from the outside of the building into the inlet compartment of the burner, and a sealed exhaust vent from the combustion chamber to the outdoors.

The direct vent/sealed combustion option is available on the Thermific® boilers on Series 700, 1000, 1200, 1500, 1700, and 2000.

Advantages are:

•Savings in energy costs due to the elimination of using conditioned air (heated and/or cooled building air) from going back up the stack.

•Isolation of the burner from pressure changes in the building which can cause erratic combustion performance.

•Combustion air is taken from the outside which is generally more clean than indoor air. Halide contaminants within a building, such as chlorides, can cause excessive corrosion in the burner, heat exchanger and venting system.

•Eliminates the need for two large combustion air/ventilation air openings into the mechanical space.

1.1CODE COMPLIANCE

1.1.1Direct Vent/Sealed Combustion System

(complying with ANSI Z21.13)

All flue gas outlet (exhaust vent) material must comply with

Introduction

1.1.2Fresh Air System

(ducted combustion air system)

In some instances compliance with ANSI Z21.13 may not be required, in which case a "fresh air system" may be used. Consultation with qualified professionals is required to determine whether a "fresh air system" is suitable for any particular application and in compliance with all applicable codes and regulations.

All flue gas outlet (exhaust vent) material for a fresh air system must be certified for use with a Category I Appliance. (Standard

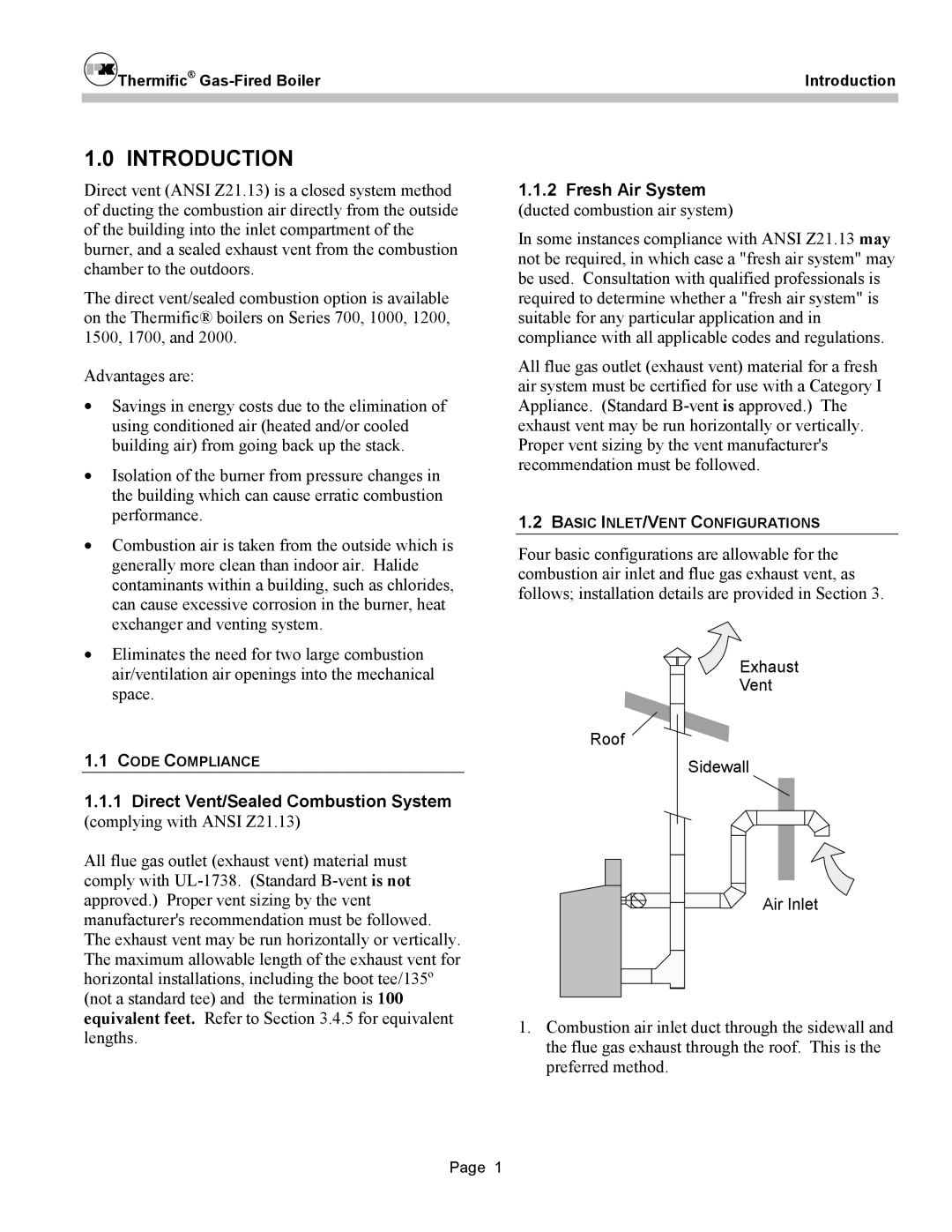

1.2BASIC INLET/VENT CONFIGURATIONS

Four basic configurations are allowable for the combustion air inlet and flue gas exhaust vent, as follows; installation details are provided in Section 3.

Exhaust

Vent

Roof

Sidewall

Air Inlet

1.Combustion air inlet duct through the sidewall and the flue gas exhaust through the roof. This is the preferred method.

Page 1