|

|

|

| Thermific® | Installation |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

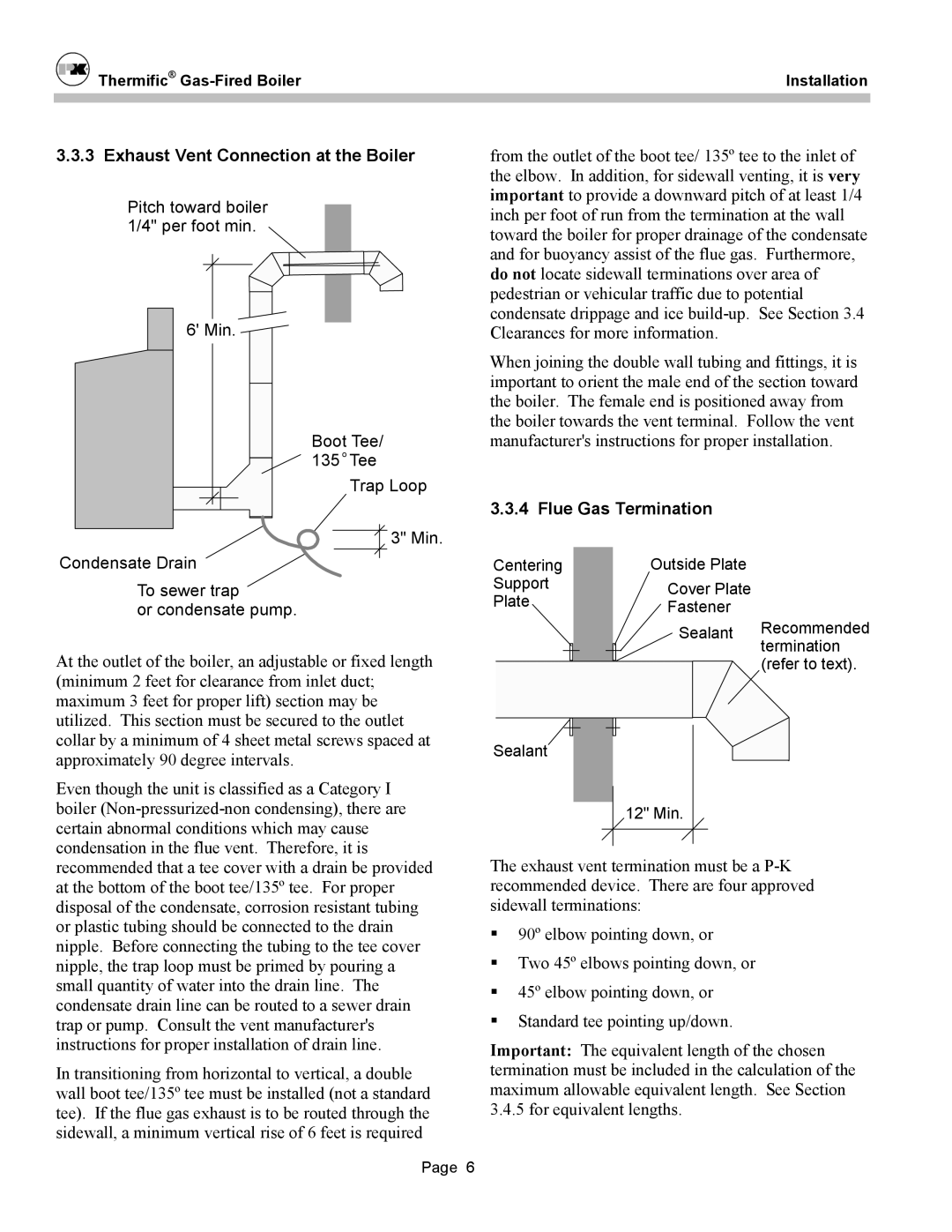

3.3.3 Exhaust Vent Connection at the Boiler

Pitch toward boiler 1/4" per foot min.

6' Min.

Boot Tee/

135 o Tee

Trap Loop

3" Min.

Condensate Drain

To sewer trap

or condensate pump.

At the outlet of the boiler, an adjustable or fixed length (minimum 2 feet for clearance from inlet duct; maximum 3 feet for proper lift) section may be utilized. This section must be secured to the outlet collar by a minimum of 4 sheet metal screws spaced at approximately 90 degree intervals.

Even though the unit is classified as a Category I boiler

In transitioning from horizontal to vertical, a double wall boot tee/135º tee must be installed (not a standard tee). If the flue gas exhaust is to be routed through the sidewall, a minimum vertical rise of 6 feet is required

from the outlet of the boot tee/ 135º tee to the inlet of the elbow. In addition, for sidewall venting, it is very important to provide a downward pitch of at least 1/4 inch per foot of run from the termination at the wall toward the boiler for proper drainage of the condensate and for buoyancy assist of the flue gas. Furthermore, do not locate sidewall terminations over area of pedestrian or vehicular traffic due to potential condensate drippage and ice

When joining the double wall tubing and fittings, it is important to orient the male end of the section toward the boiler. The female end is positioned away from the boiler towards the vent terminal. Follow the vent manufacturer's instructions for proper installation.

3.3.4 Flue Gas Termination

Centering |

|

|

|

|

| Outside Plate |

|

Support |

|

|

|

|

| Cover Plate |

|

Plate |

|

|

|

|

|

| |

|

|

|

|

| Fastener |

| |

|

|

|

|

|

|

| |

|

|

|

|

|

| Sealant | Recommended |

|

|

|

|

|

| termination | |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| (refer to text). |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

Sealant

12" Min.

The exhaust vent termination must be a

90º elbow pointing down, or

Two 45º elbows pointing down, or

45º elbow pointing down, or

Standard tee pointing up/down.

Important: The equivalent length of the chosen termination must be included in the calculation of the maximum allowable equivalent length. See Section 3.4.5 for equivalent lengths.

Page 6