Installation to Double Wood Stud Wall

![]() WARNING

WARNING

•Installer must verify that the supporting surface will safely support the combined load of the equipment and all at- tached hardware and components.

•Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the screws, greatly reducing their holding power.

•Never tighten in excess of 80 in. • lb (9 N.M.).

•Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder is highly recommended.

•Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs. Installers are responsible to provide hardware for other types of mounting situations (not UL evaluated).

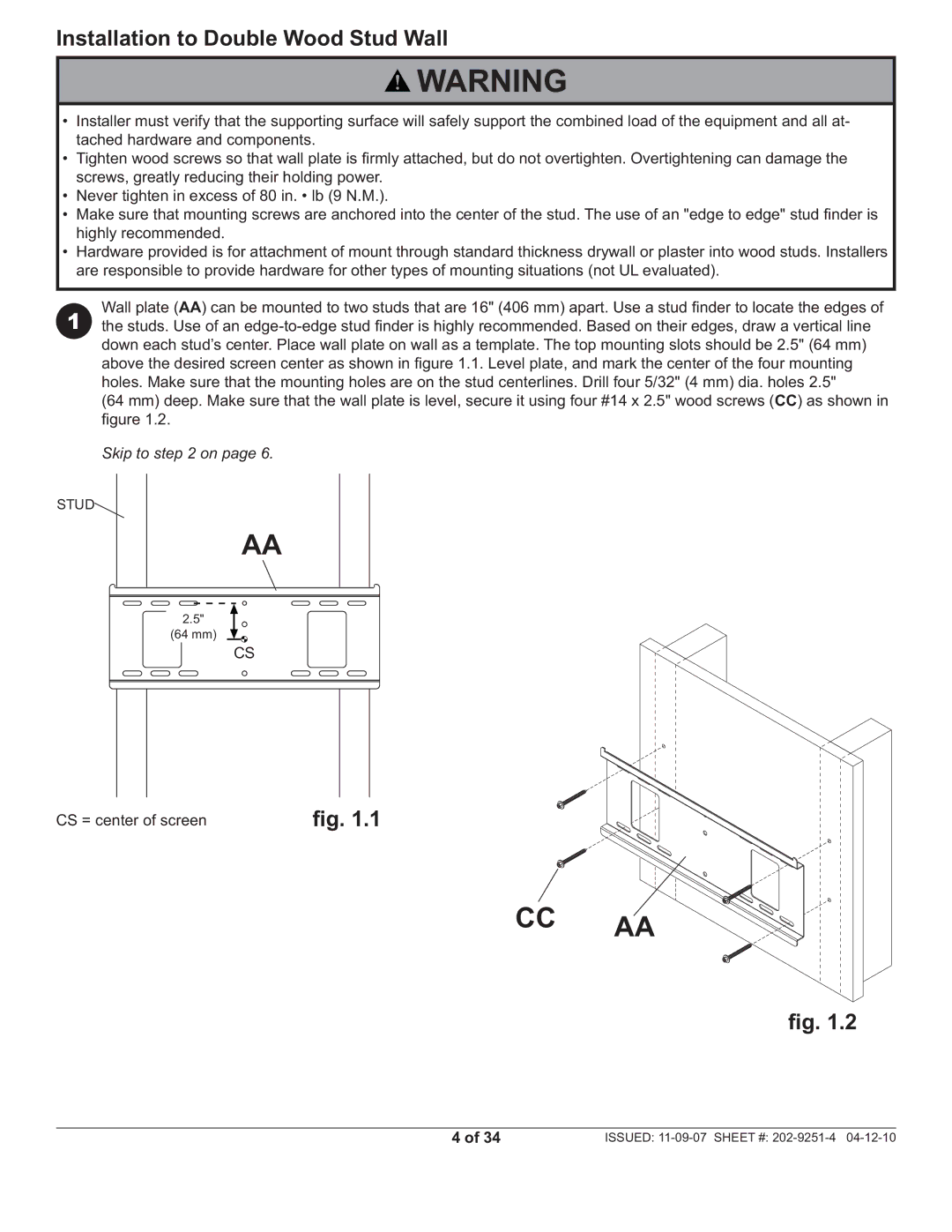

Wall plate (AA) can be mounted to two studs that are 16" (406 mm) apart. Use a stud fi nder to locate the edges of

1 the studs. Use of an

(64 mm) deep. Make sure that the wall plate is level, secure it using four #14 x 2.5" wood screws (CC) as shown in fi gure 1.2.

Skip to step 2 on page 6.

STUD![]()

AA

2.5"

(64 mm)

CS

CS = center of screen | fig. 1.1 |

CC AA

fig. 1.2

4 of 34 | ISSUED: |