READ AND FOLLOW ALL INSTRUCTIONS

GENERAL:

Our shipping container has been specifically designed to prevent transit damage. However, any indications of damage should be carefully noted on the delivery ticket and a claim filed promptly with the carrier.

LOCATION:

Locate the pump as close as possible to the pool. Provide the necessary space around the pump for future inspection and servicing of the unit. If possible, allow several inches of clearance below the motor to floor to allow easy access to mounting screw. Locate away from pool chemicals to prevent spilling on or near motor.

INSTALLATION:

The pump suction line should not be smaller than the pipe size on the inlet of the pump.

Your pump is made of the finest engineering materials available today. A few simple precautions taken during the initial installation, will insure many long years of trouble-free operation.

The threads of pipe fittings screwed into pump must be sealed with: pipe sealant, Teflon® Tape, R.T.V. or other sealing materials approved for pipe threads.

Tighten the pump fitting only as much as is required to insure a tight connection. DO NOT OVER TIGHTEN.

The piping should be supported independently and not supported by the pump.

The pump motor must be wired for the proper voltage, and rotation, in accordance with the wiring diagram supplied with the motor. All wiring should be done by a licensed electrician in accordance with local codes, be certain that the motor frame is grounded. Use lug on top of motor frame to bond together motor and all metallic parts of pool, spa or hot tub structure and to all electrical equipment, metal conduit, and metal piping within 5 feet of the inside walls of a swimming pool, spa or hot tub, when the motor is installed within 5 feet of the inside walls of the swimming pool, spa or hot tub structure with a solid copper conductor not less than No. 8 A.W.G.

Motor name plate has voltage, phase, ampere draw and other motor information. Terminal cover plate or name plate has wiring connection informa- tion.

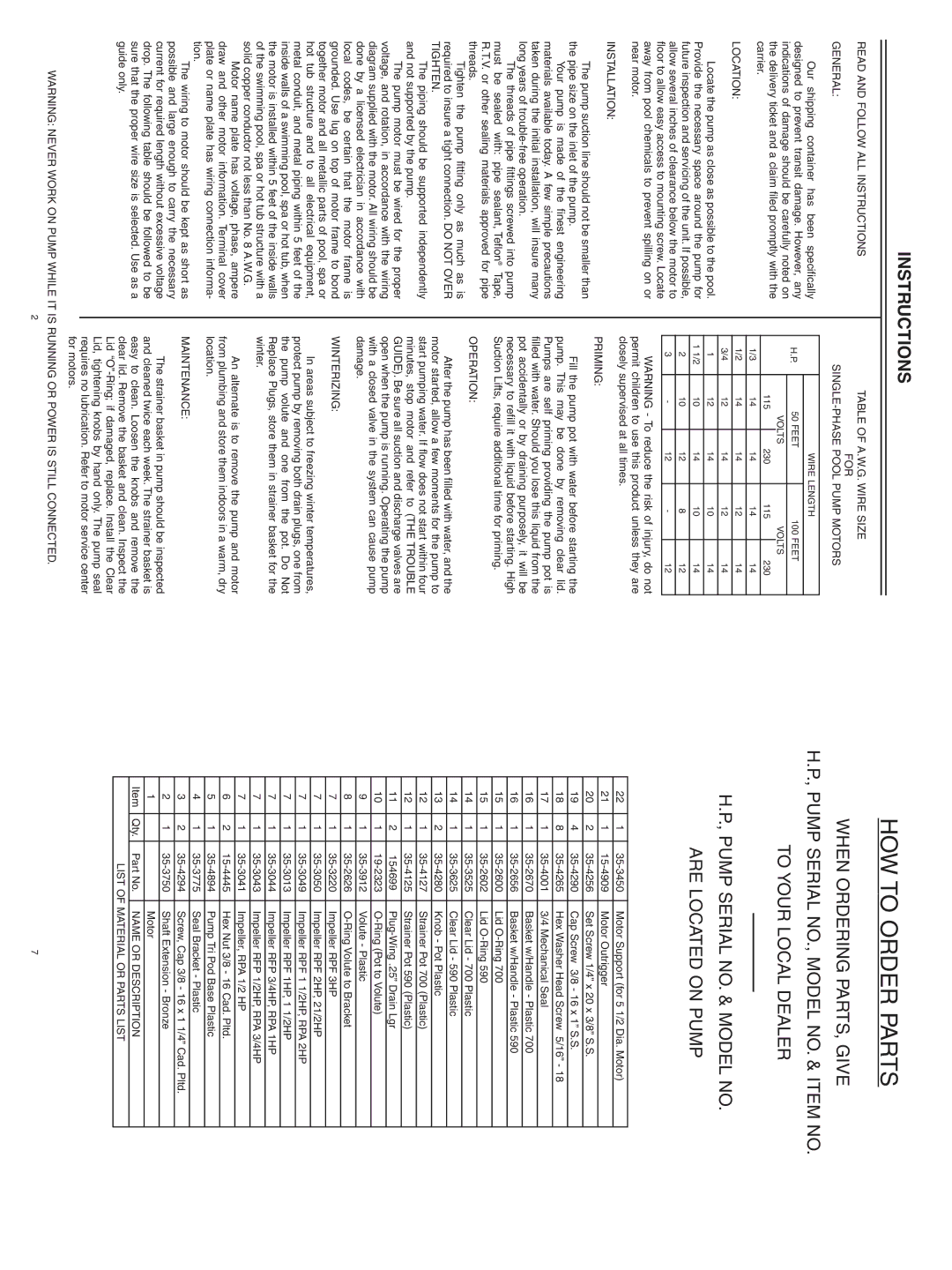

The wiring to motor should be kept as short as possible and large enough to carry the necessary current for required length without excessive voltage drop. The following table should be followed to be sure that the proper wire size is selected. Use as a guide only.

TABLE OF A.W.G. WIRE SIZE

FOR

SINGLE-PHASE POOL PUMP MOTORS

| | | WIRE LENGTH | | |

| | | | | | |

H.P. | | 50 FEET | | 100 FEET |

| | VOLTS | | VOLTS |

| 115 | | 230 | 115 | | 230 |

1/3 | 14 | | 14 | 14 | | 14 |

1/2 | 14 | | 14 | 12 | | 14 |

3/4 | 12 | | 14 | 12 | | 14 |

1 | 12 | | 14 | 10 | | 14 |

1 1/2 | 10 | | 14 | 10 | | 14 |

2 | 10 | | 12 | 8 | | 12 |

| | | | | | |

3 | - | | 12 | - | | 12 |

WARNING - To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times.

PRIMING:

Fill the pump pot with water before starting the pump. This may be done by removing clear lid. Pumps are self priming providing the pump pot is filled with water. Should you lose this liquid from the pot accidentally or by draining purposely, it will be necessary to refill it with liquid before starting. High Suction Lifts, require additional time for priming.

OPERATION:

After the pump has been filled with water, and the motor started, allow a few moments for the pump to start pumping water. If flow does not start within four minutes, stop motor and refer to (THE TROUBLE GUIDE). Be sure all suction and discharge valves are open when the pump is running. Operating the pump with a closed valve in the system can cause pump damage.

WINTERIZING:

In areas subject to freezing winter temperatures, protect pump by removing both drain plugs, one from the pump volute and one from the pot. Do Not Replace Plugs, store them in strainer basket for the winter.

An alternate is to remove the pump and motor from plumbing and store them indoors in a warm, dry location.

MAINTENANCE:

The strainer basket in pump should be inspected and cleaned twice each week. The strainer basket is easy to clean. Loosen the knobs and remove the clear lid. Remove the basket and clean. Inspect the Lid “O”-Ring; if damaged, replace. Install the Clear Lid, tightening knobs by hand only. The pump seal requires no lubrication. Refer to motor service center for motors.

WHEN ORDERING PARTS, GIVE

H.P., PUMP SERIAL NO., MODEL NO. & ITEM NO.

TO YOUR LOCAL DEALER

--------------------

H.P., PUMP SERIAL NO. & MODEL NO.

ARE LOCATED ON PUMP

22 | 1 | 35-3450 | Motor Support (for 5 1/2 Dia. Motor) |

21 | 1 | 15-4909 | Motor Outrigger |

20 | 2 | 35-4256 | Set Screw 1/4” x 20 x 3/8” S.S. |

19 | 4 | 35-4290 | Cap Screw 3/8 - 16 x 1” S.S. |

18 | 8 | 35-4265 | Hex Washer Head Screw 5/16” - 18 |

17 | 1 | 35-4001 | 3/4 Mechanical Seal |

16 | 1 | 35-2670 | Basket w/Handle - Plastic 700 |

16 | 1 | 35-2656 | Basket w/Handle - Plastic 590 |

15 | 1 | 35-2600 | Lid O-Ring 700 |

15 | 1 | 35-2602 | Lid O-Ring 590 |

14 | 1 | 35-3525 | Clear Lid - 700 Plastic |

14 | 1 | 35-3625 | Clear Lid - 590 Plastic |

13 | 2 | 35-4280 | Knob - Pot Plastic |

12 | 1 | 35-4127 | Strainer Pot 700 (Plastic) |

12 | 1 | 35-4125 | Strainer Pot 590 (Plastic) |

11 | 2 | 154699 | Plug-Wing .25” Drain Lgr |

10 | 1 | 19-2323 | O-Ring (Pot to Volute) |

9 | 1 | 35-3912 | Volute - Plastic |

8 | 1 | 35-2626 | O-Ring Volute to Bracket |

7 | 1 | 35-3220 | Impeller RPF 3HP |

7 | 1 | 35-3050 | Impeller RPF 2HP, 21/2HP |

7 | 1 | 35-3049 | Impeller RPF 1 1/2HP, RPA 2HP |

7 | 1 | 35-3013 | Impeller RPF 1HP, 1 1/2HP |

7 | 1 | 35-3044 | Impeller RFP 3/4HP, RPA 1HP |

7 | 1 | 35-3043 | Impeller RFP 1/2HP, RPA 3/4HP |

7 | 1 | 35-3041 | Impeller, RPA 1/2 HP |

6 | 2 | 15-4445 | Hex Nut 3/8 - 16 Cad. Pltd. |

5 | 1 | 35-4894 | Pump Tri Pod Base Plastic |

4 | 1 | 35-3775 | Seal Bracket - Plastic |

3 | 2 | 35-4294 | Screw, Cap 3/8 - 16 x 1 1/4” Cad. Pltd. |

2 | 1 | 35-3750 | Shaft Extension - Bronze |

1 | | | Motor |

Item | Qty. | Part No. | NAME OR DESCRIPTION |

| | LIST OF MATERIAL OR PARTS LIST |