Advance

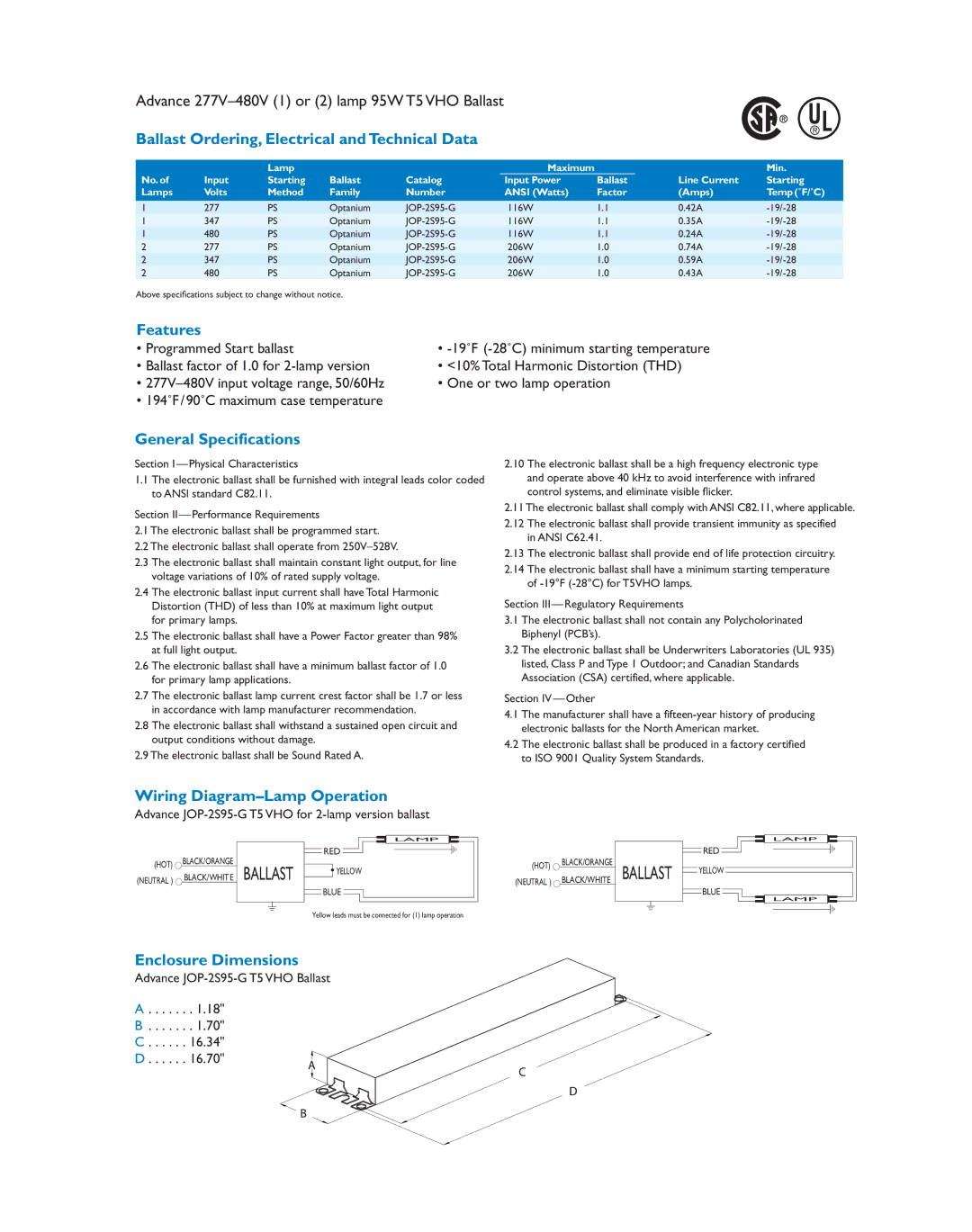

Ballast Ordering, Electrical and Technical Data

|

| Lamp |

|

| Maximum |

|

| Min. |

No. of | Input | Starting | Ballast | Catalog | Input Power | Ballast | Line Current | Starting |

Lamps | Volts | Method | Family | Number | ANSI (Watts) | Factor | (Amps) | Temp (˚F/˚C) |

1 | 277 | PS | Optanium | 116W | 1.1 | 0.42A | ||

1 | 347 | PS | Optanium | 116W | 1.1 | 0.35A | ||

1 | 480 | PS | Optanium | 116W | 1.1 | 0.24A | ||

2 | 277 | PS | Optanium | 206W | 1.0 | 0.74A | ||

2 | 347 | PS | Optanium | 206W | 1.0 | 0.59A | ||

2 | 480 | PS | Optanium | 206W | 1.0 | 0.43A |

Above specifications subject to change without notice.

Features

• Programmed Start ballast | • |

• Ballast factor of 1.0 for | • <10% Total Harmonic Distortion (THD) |

• | • One or two lamp operation |

• 194˚F/ 90˚C maximum case temperature |

|

General Specifications

Section I — Physical Characteristics

1.1The electronic ballast shall be furnished with integral leads color coded to ANSI standard C82.11.

Section II — Performance Requirements

2.1The electronic ballast shall be programmed start.

2.2The electronic ballast shall operate from

2.3The electronic ballast shall maintain constant light output, for line voltage variations of 10% of rated supply voltage.

2.4The electronic ballast input current shall have Total Harmonic Distortion (THD) of less than 10% at maximum light output for primary lamps.

2.5The electronic ballast shall have a Power Factor greater than 98% at full light output.

2.6The electronic ballast shall have a minimum ballast factor of 1.0 for primary lamp applications.

2.7The electronic ballast lamp current crest factor shall be 1.7 or less in accordance with lamp manufacturer recommendation.

2.8The electronic ballast shall withstand a sustained open circuit and output conditions without damage.

2.9The electronic ballast shall be Sound Rated A.

2.10The electronic ballast shall be a high frequency electronic type and operate above 40 kHz to avoid interference with infrared control systems, and eliminate visible flicker.

2.11The electronic ballast shall comply with ANSI C82.11, where applicable.

2.12The electronic ballast shall provide transient immunity as specified in ANSI C62.41.

2.13The electronic ballast shall provide end of life protection circuitry.

2.14The electronic ballast shall have a minimum starting temperature of

Section III — Regulatory Requirements

3.1The electronic ballast shall not contain any Polycholorinated Biphenyl (PCB’s).

3.2The electronic ballast shall be Underwriters Laboratories (UL 935) listed, Class P and Type 1 Outdoor; and Canadian Standards Association (CSA) certified, where applicable.

Section IV — Other

4.1The manufacturer shall have a

4.2The electronic ballast shall be produced in a factory certified to ISO 9001 Quality System Standards.

Wiring Diagram–Lamp Operation

Advance

LAMP

| BLACK/ORANGE |

| RED | |

(HOT) | BALLAST | YELLOW | ||

(NEUTRAL ) | BLACK/WHITE | |||

|

![]() BLUE

BLUE ![]()

![]()

Yellow leads must be connected for (1) lamp operation

Enclosure Dimensions

Advance

A. . . . . . . 1.18"

B. . . . . . . 1.70"

C. . . . . . 16.34"

D. . . . . . 16.70"

(HOT) BLACK/ORANGE

(NEUTRAL ) BLACK/WHITE

LAMP

![]() RED

RED ![]()

BALLAST  YELLOW

YELLOW

![]() BLUE

BLUE ![]()

![]()

LAMP