SPX Operation Manual | 11 |

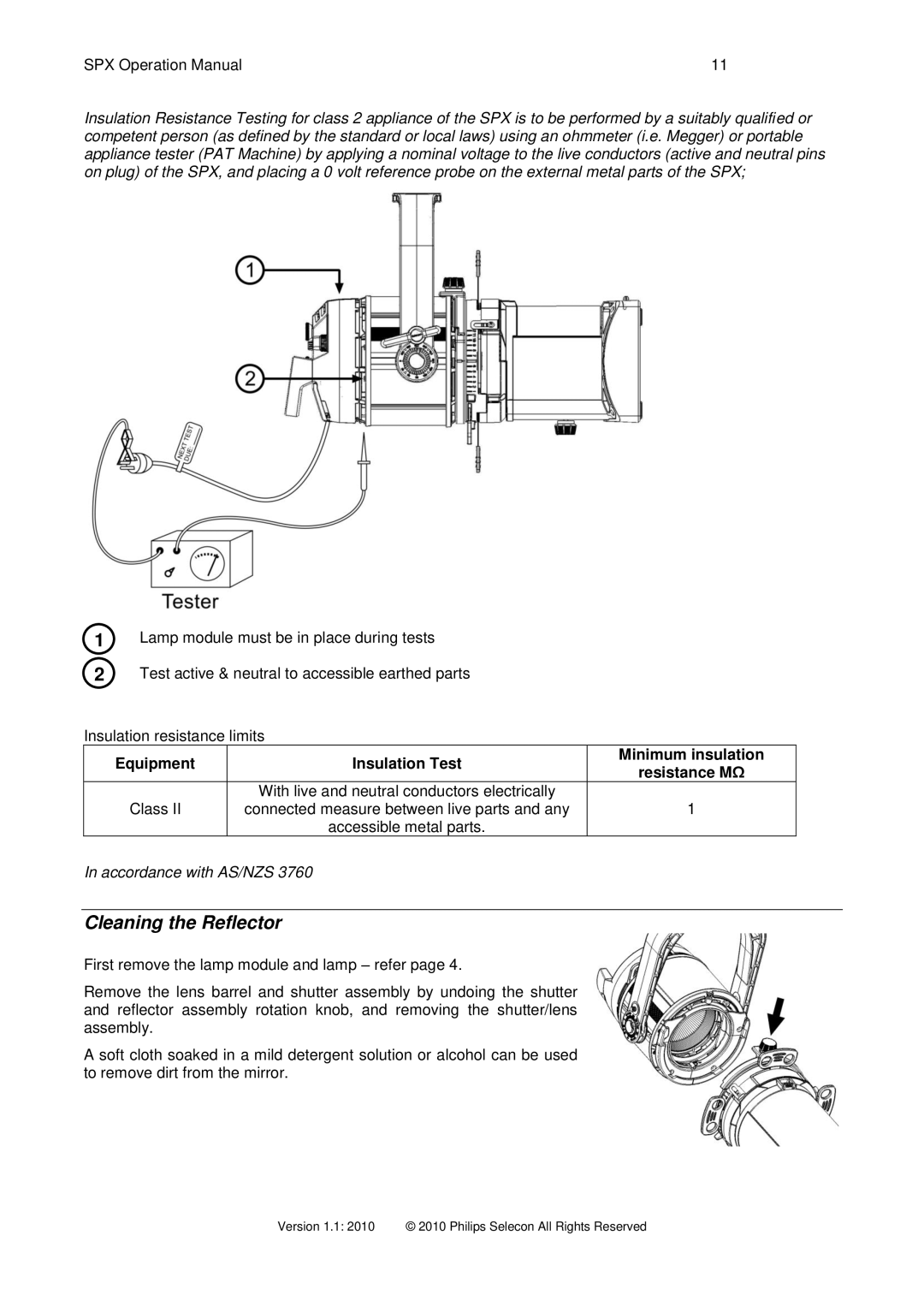

Insulation Resistance Testing for class 2 appliance of the SPX is to be performed by a suitably qualified or competent person (as defined by the standard or local laws) using an ohmmeter (i.e. Megger) or portable appliance tester (PAT Machine) by applying a nominal voltage to the live conductors (active and neutral pins on plug) of the SPX, and placing a 0 volt reference probe on the external metal parts of the SPX;

1Lamp module must be in place during tests

2Test active & neutral to accessible earthed parts

Insulation resistance limits

Equipment | Insulation Test | Minimum insulation | |

resistance MΩ | |||

|

| ||

| With live and neutral conductors electrically |

| |

Class II | connected measure between live parts and any | 1 | |

| accessible metal parts. |

|

In accordance with AS/NZS 3760

Cleaning the Reflector

First remove the lamp module and lamp – refer page 4.

Remove the lens barrel and shutter assembly by undoing the shutter and reflector assembly rotation knob, and removing the shutter/lens assembly.

A soft cloth soaked in a mild detergent solution or alcohol can be used to remove dirt from the mirror.