2000 specifications

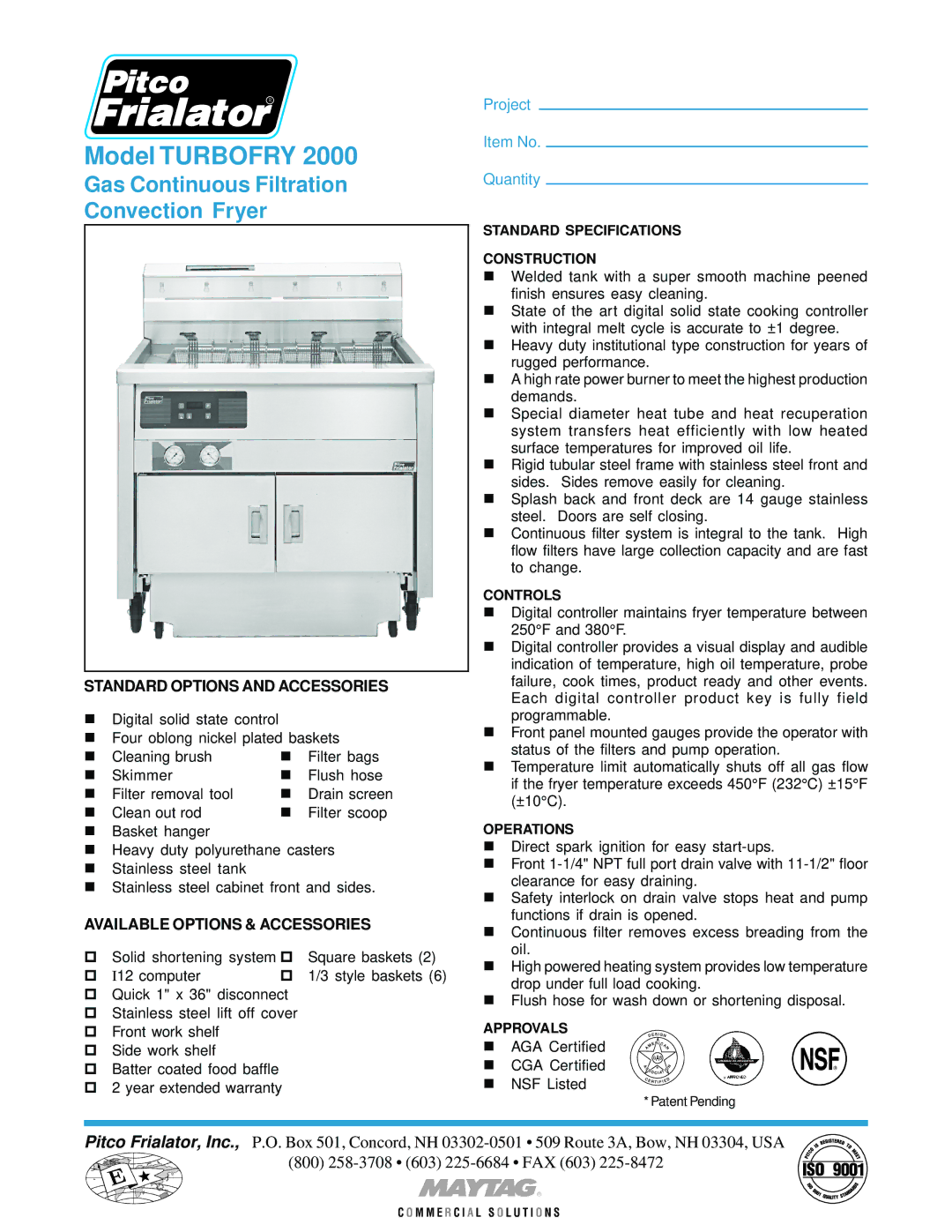

The Pitco Frialator 2000 is a state-of-the-art commercial deep frying solution designed to meet the demanding needs of restaurants, cafes, and food service operations. Known for its reliability and efficiency, the Frialator 2000 stands out in the competitive landscape of frying equipment. This machine is engineered to deliver exceptional performance while ensuring ease of use and maintenance.One of the most notable features of the Pitco Frialator 2000 is its robust construction and design. Equipped with a high-capacity frying tank, it can handle large volumes of food, making it ideal for busy kitchens. The unit typically holds 50 to 60 pounds of oil, allowing chefs to fry various items simultaneously without sacrificing quality or consistency.

The Frialator 2000 incorporates advanced heating technology, which significantly reduces recovery time and maintains oil temperature even during peak cooking hours. This feature enables quick food turnaround, ensuring that customers receive their orders promptly. The unit is also designed for energy efficiency, helping to reduce operating costs while delivering optimum frying performance.

Safety is a priority in the design of the Pitco Frialator 2000. The model includes features such as built-in oil drain valves and automatic shut-off systems, which enhance operational safety. Additionally, the fryer's exterior remains cool to the touch, minimizing the risk of burns or accidents in a bustling kitchen environment.

User-friendly controls are another highlight of the Frialator 2000, allowing chefs to set precise frying temperatures easily. The digital control panel offers real-time temperature readings, helping operators monitor frying conditions and achieve perfect results every time. The fryer also comes equipped with a filtration system, which extends the life of the oil and enhances the flavor quality of fried foods.

Moreover, the Pitco Frialator 2000 is designed for easy maintenance. Its removable components, such as the fry pot and basket, simplify the cleaning process, making it easy for staff to maintain hygiene standards. The unit’s seamless welding construction also prevents food debris accumulation, ensuring that the fryer remains in optimal condition.

In conclusion, the Pitco Frialator 2000 combines innovation with practicality, offering a comprehensive solution for commercial frying needs. With its emphasis on efficiency, safety, and ease of use, it has become a preferred choice among food service professionals looking to elevate their frying capabilities.