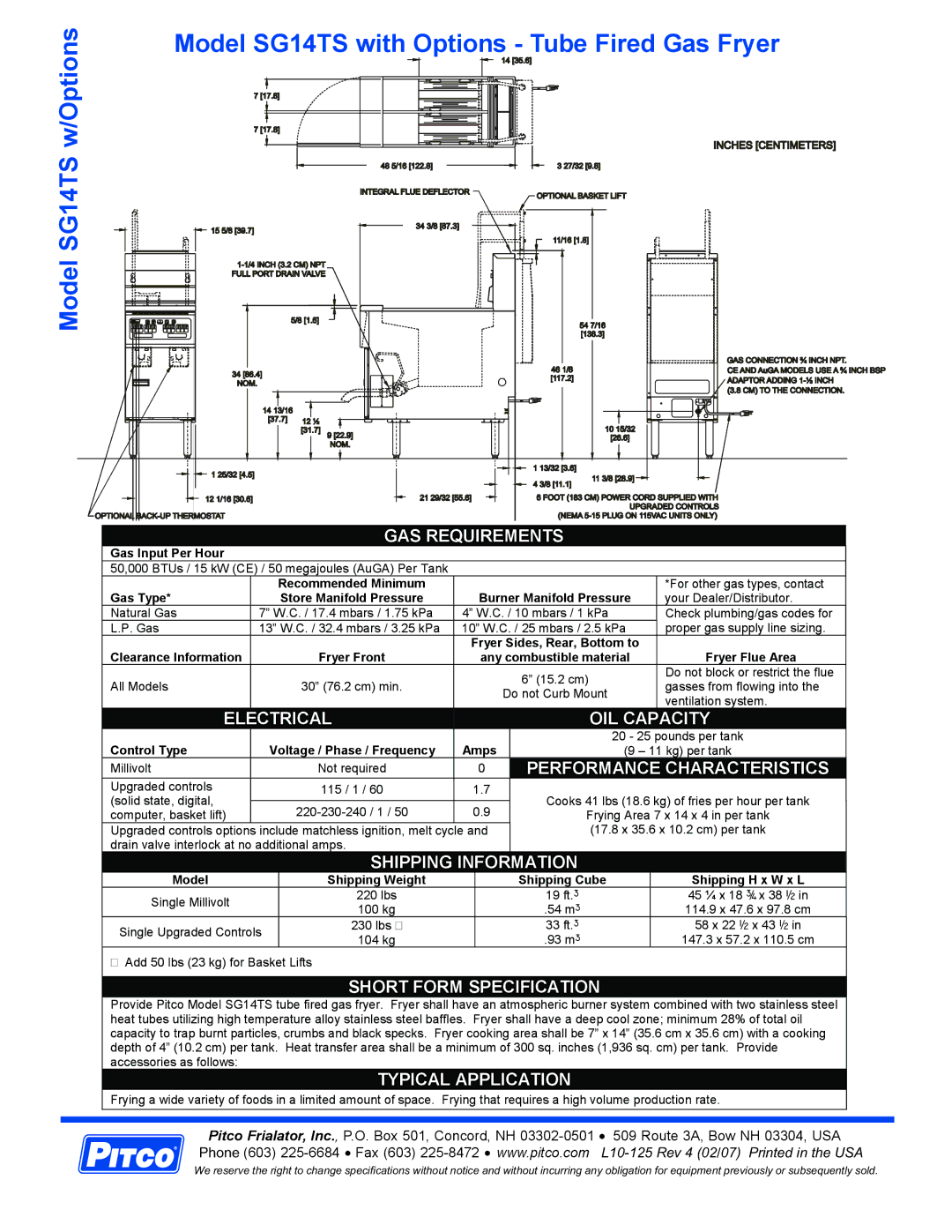

SG14TS specifications

The Pitco Frialator SG14TS is a top-tier frying solution designed to meet the demands of commercial kitchens. Known for its robustness and efficiency, the SG14TS is an essential asset for operators who prioritize both quality and speed in food preparation.One of the key features of the SG14TS is its 40-pound oil capacity, allowing for extended frying sessions without the need for constant refilling. This substantial capacity pairs well with its powerful heating element, which ensures quick recovery times and consistent frying temperatures. The unit’s stainless steel construction adds to its durability while also providing an easy-to-clean surface that helps maintain hygiene in busy kitchen environments.

The SG14TS is equipped with advanced temperature control technology, featuring a precise adjustable thermostat that allows chefs to set and maintain the desired cooking temperature accurately. This precision not only enhances food quality but also helps in energy efficiency, reducing operational costs. Additionally, the unit includes a built-in safety feature, which automatically shuts off the heating element if the oil reaches a dangerous temperature, thus preventing any risk of overheating.

Another standout characteristic is the efficient filtration system that the SG14TS utilizes. This system extends the life of the cooking oil by filtering out food particles after each fry cycle, yielding a cleaner and more appealing final product. The resultant oil longevity not only improves the taste of the fried items but also contributes to significant savings over time.

The SG14TS comes with user-friendly controls, making it easy for kitchen staff to operate even during high-pressure service periods. Its compact design allows it to fit into smaller spaces without compromising on performance.

Designed with versatility in mind, the Pitco Frialator SG14TS is suitable for a variety of frying applications, from French fries to chicken, and even doughnuts. Its adaptability makes it an ideal choice for restaurants, food trucks, and catering operations.

In summary, the Pitco Frialator SG14TS combines advanced frying technologies with practical features to deliver exceptional frying performance. The robust design, efficient oil filtration, and precise temperature control make it a reliable and high-performing piece of equipment for any commercial kitchen looking to enhance its frying capabilities.