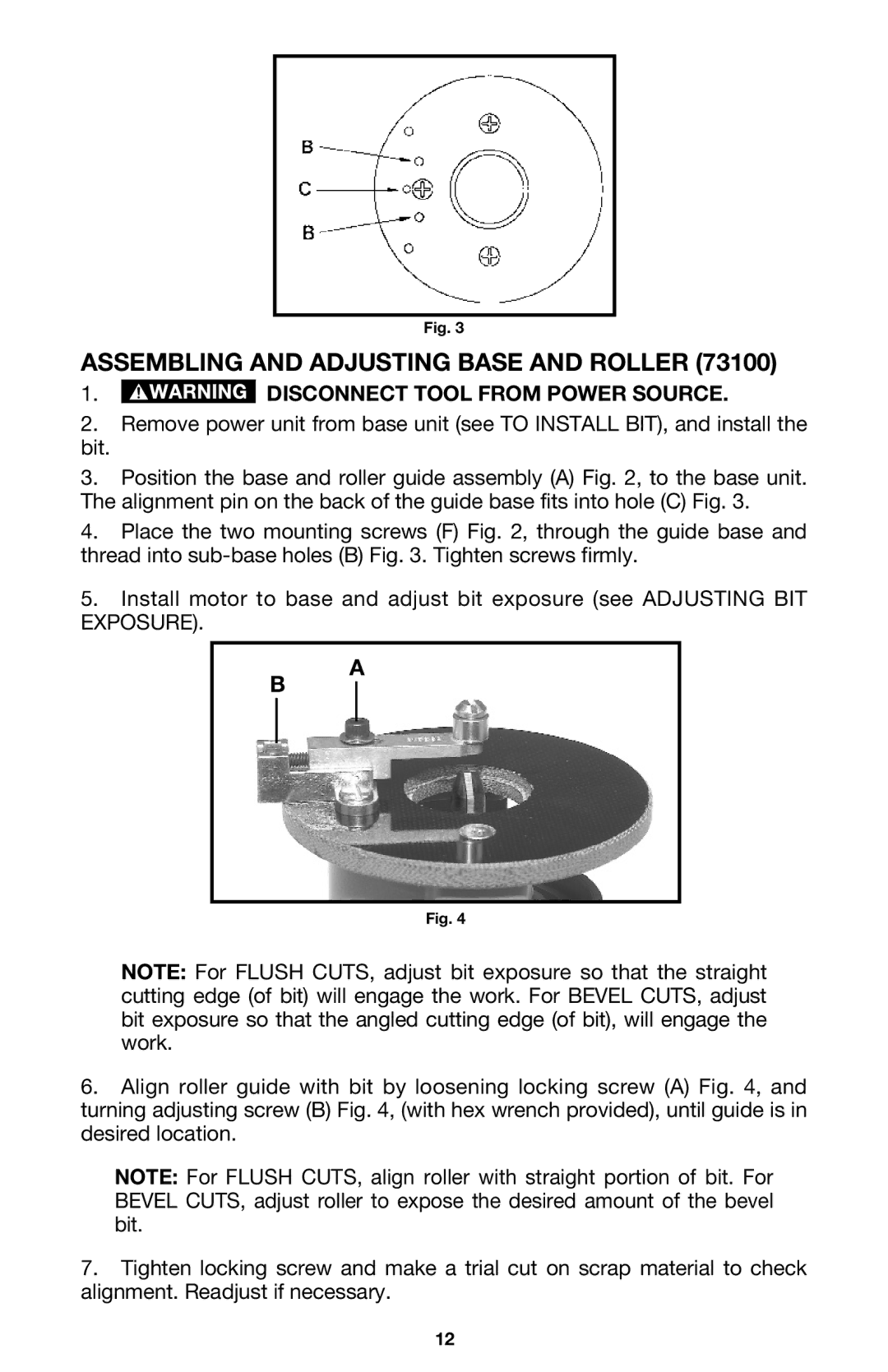

Fig. 3

ASSEMBLING AND ADJUSTING BASE AND ROLLER (73100)

1. DISCONNECT TOOL FROM POWER SOURCE.

DISCONNECT TOOL FROM POWER SOURCE.

2.Remove power unit from base unit (see TO INSTALL BIT), and install the

bit.

3.Position the base and roller guide assembly (A) Fig. 2, to the base unit. The alignment pin on the back of the guide base fits into hole (C) Fig. 3.

4.Place the two mounting screws (F) Fig. 2, through the guide base and thread into

5.Install motor to base and adjust bit exposure (see ADJUSTING BIT EXPOSURE).

A

B

Fig. 4

NOTE: For FLUSH CUTS, adjust bit exposure so that the straight cutting edge (of bit) will engage the work. For BEVEL CUTS, adjust bit exposure so that the angled cutting edge (of bit), will engage the work.

6.Align roller guide with bit by loosening locking screw (A) Fig. 4, and turning adjusting screw (B) Fig. 4, (with hex wrench provided), until guide is in desired location.

NOTE: For FLUSH CUTS, align roller with straight portion of bit. For BEVEL CUTS, adjust roller to expose the desired amount of the bevel bit.

7.Tighten locking screw and make a trial cut on scrap material to check alignment. Readjust if necessary.

12