ADJUSTING DOWNWARD TRAVEL OF SAW BLADE

DISCONNECT THE MACHINE FROM THE

POWER SOURCE.

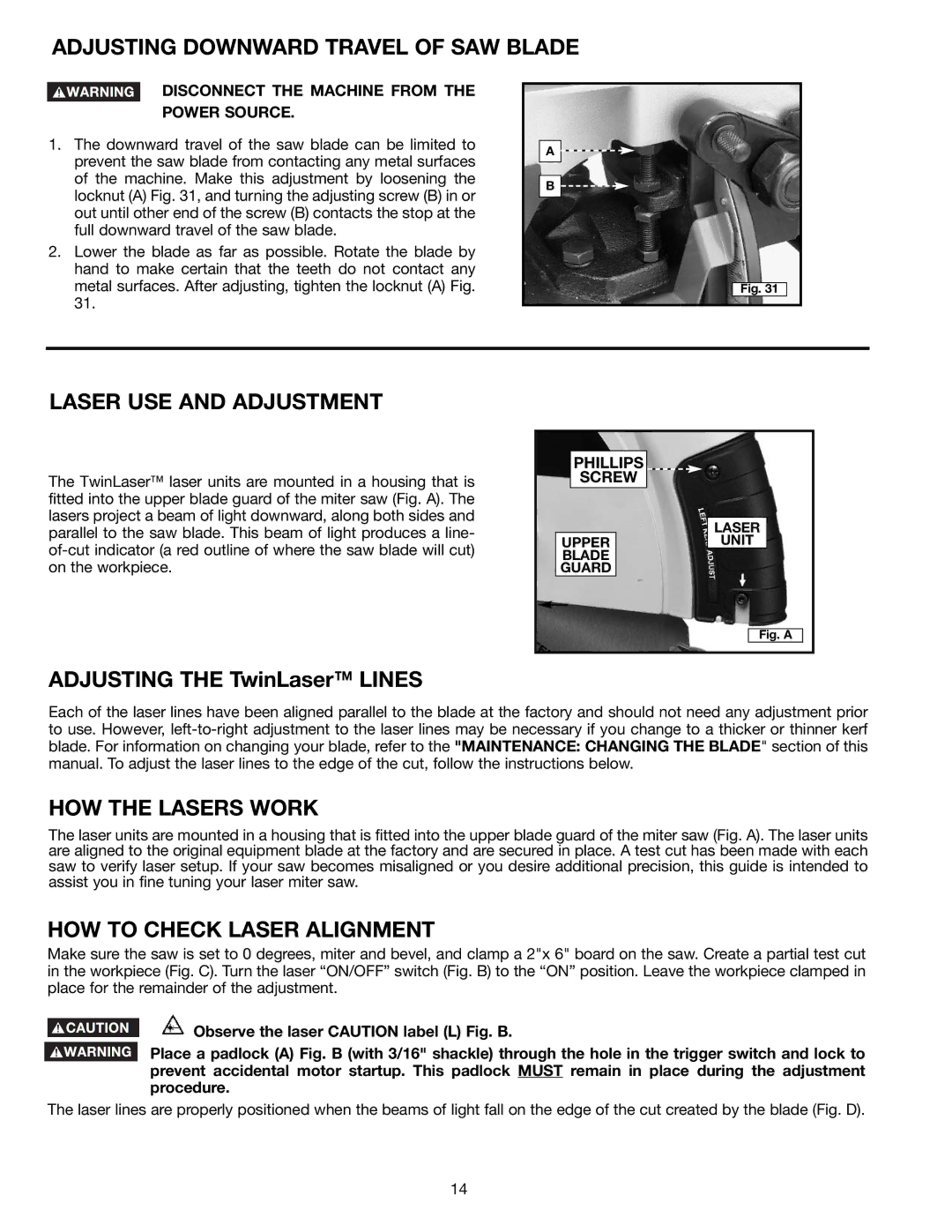

1.The downward travel of the saw blade can be limited to prevent the saw blade from contacting any metal surfaces of the machine. Make this adjustment by loosening the locknut (A) Fig. 31, and turning the adjusting screw (B) in or out until other end of the screw (B) contacts the stop at the full downward travel of the saw blade.

2.Lower the blade as far as possible. Rotate the blade by hand to make certain that the teeth do not contact any metal surfaces. After adjusting, tighten the locknut (A) Fig. 31.

A![]()

![]()

B![]()

![]()

Fig. 31

LASER USE AND ADJUSTMENT

The TwinLaser™ laser units are mounted in a housing that is fitted into the upper blade guard of the miter saw (Fig. A). The lasers project a beam of light downward, along both sides and parallel to the saw blade. This beam of light produces a line-

PHILLIPS |

|

SCREW |

|

| LASER |

UPPER | UNIT |

BLADE |

|

GUARD |

|

| Fig. A |

ADJUSTING THE TwinLaser™ LINES

Each of the laser lines have been aligned parallel to the blade at the factory and should not need any adjustment prior to use. However,

HOW THE LASERS WORK

The laser units are mounted in a housing that is fitted into the upper blade guard of the miter saw (Fig. A). The laser units are aligned to the original equipment blade at the factory and are secured in place. A test cut has been made with each saw to verify laser setup. If your saw becomes misaligned or you desire additional precision, this guide is intended to assist you in fine tuning your laser miter saw.

HOW TO CHECK LASER ALIGNMENT

Make sure the saw is set to 0 degrees, miter and bevel, and clamp a 2"x 6" board on the saw. Create a partial test cut in the workpiece (Fig. C). Turn the laser “ON/OFF” switch (Fig. B) to the “ON” position. Leave the workpiece clamped in place for the remainder of the adjustment.

![]() Observe the laser CAUTION label (L) Fig. B.

Observe the laser CAUTION label (L) Fig. B.

Place a padlock (A) Fig. B (with 3/16" shackle) through the hole in the trigger switch and lock to prevent accidental motor startup. This padlock MUST remain in place during the adjustment procedure.

The laser lines are properly positioned when the beams of light fall on the edge of the cut created by the blade (Fig. D).

14