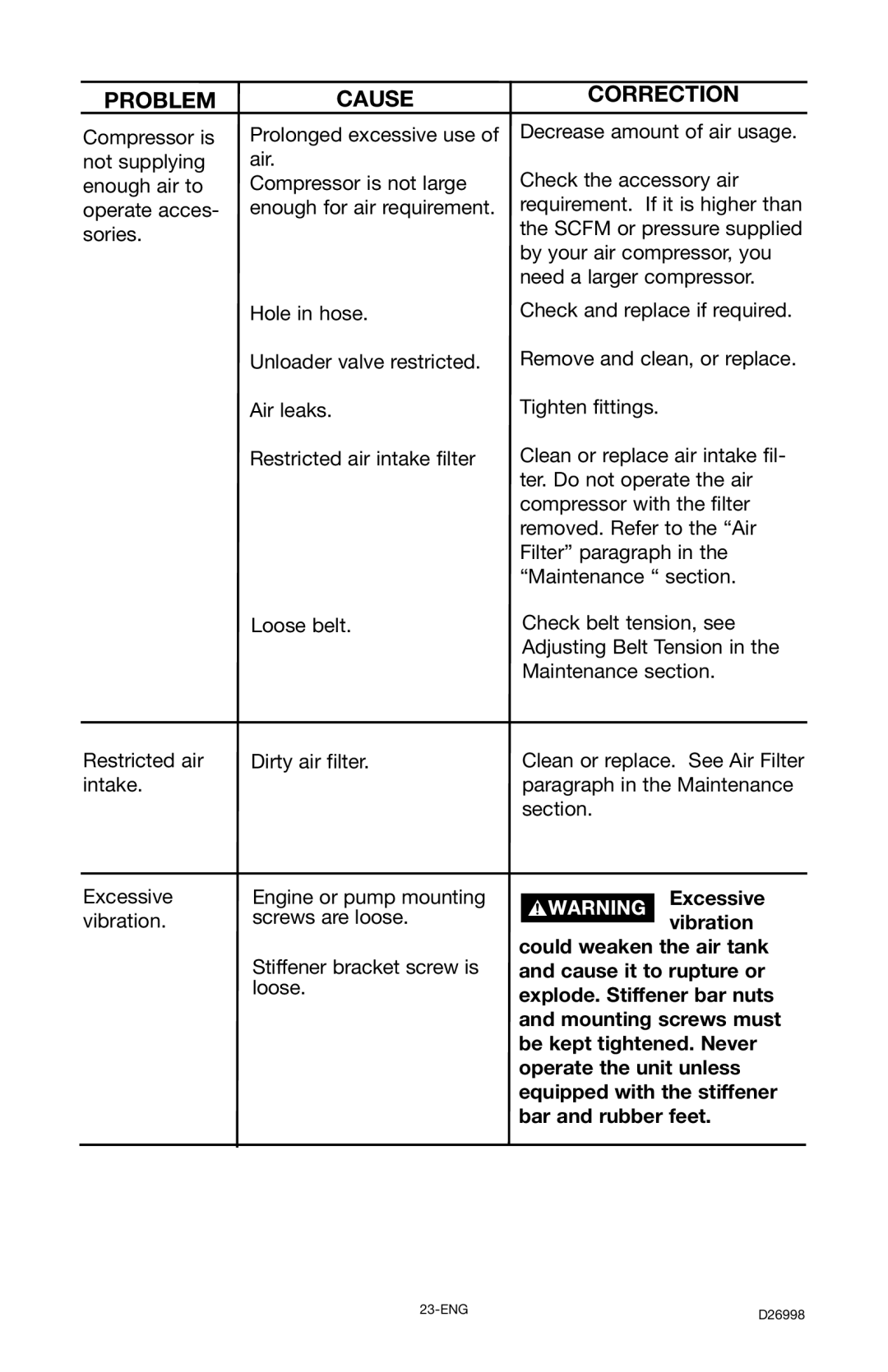

PROBLEM | CAUSE | CORRECTION |

Compressor is | Prolonged excessive use of |

not supplying | air. |

enough air to | Compressor is not large |

operate acces- | enough for air requirement. |

sories. |

|

| Hole in hose. |

| Unloader valve restricted. |

| Air leaks. |

| Restricted air intake filter |

Decrease amount of air usage.

Check the accessory air requirement. If it is higher than the SCFM or pressure supplied by your air compressor, you need a larger compressor.

Check and replace if required.

Remove and clean, or replace.

Tighten fittings.

Clean or replace air intake fil- ter. Do not operate the air compressor with the filter removed. Refer to the “Air Filter” paragraph in the “Maintenance “ section.

| Loose belt. | Check belt tension, see |

|

| Adjusting Belt Tension in the |

|

| Maintenance section. |

|

|

|

Restricted air | Dirty air filter. | Clean or replace. See Air Filter |

intake. |

| paragraph in the Maintenance |

|

| section. |

Excessive | Engine or pump mounting |

vibration. | screws are loose. |

| Stiffener bracket screw is |

| loose. |

Excessive vibration

could weaken the air tank and cause it to rupture or explode. Stiffener bar nuts and mounting screws must be kept tightened. Never operate the unit unless equipped with the stiffener bar and rubber feet.

D26998 |