DUTY CYCLE

This air compressor pump is capable of running continuously. However, to prolong the life of your air compressor, it is recommended that a 50%-75% average duty cycle be maintained; that is, the air compressor pump should not run more than 30-45 minutes in any given hour.

ASSEMBLY

UNPACKING

Remove unit from carton and discard all packaging.

INSTALLATION

HOW TO SET UP YOUR UNIT

Location of the Air Compressor

•Locate the air compressor in a clean, dry and well ventilated area.

•The air compressor should be located at least 12" (30.5 cm) away from the wall or other obstructions that will interfere with the flow of air.

•The air compressor pump and shroud are designed to allow for proper cooling. The ventilation openings on the compressor are necessary to maintain proper operating temperature. Do not place rags or other containers on or near these openings.

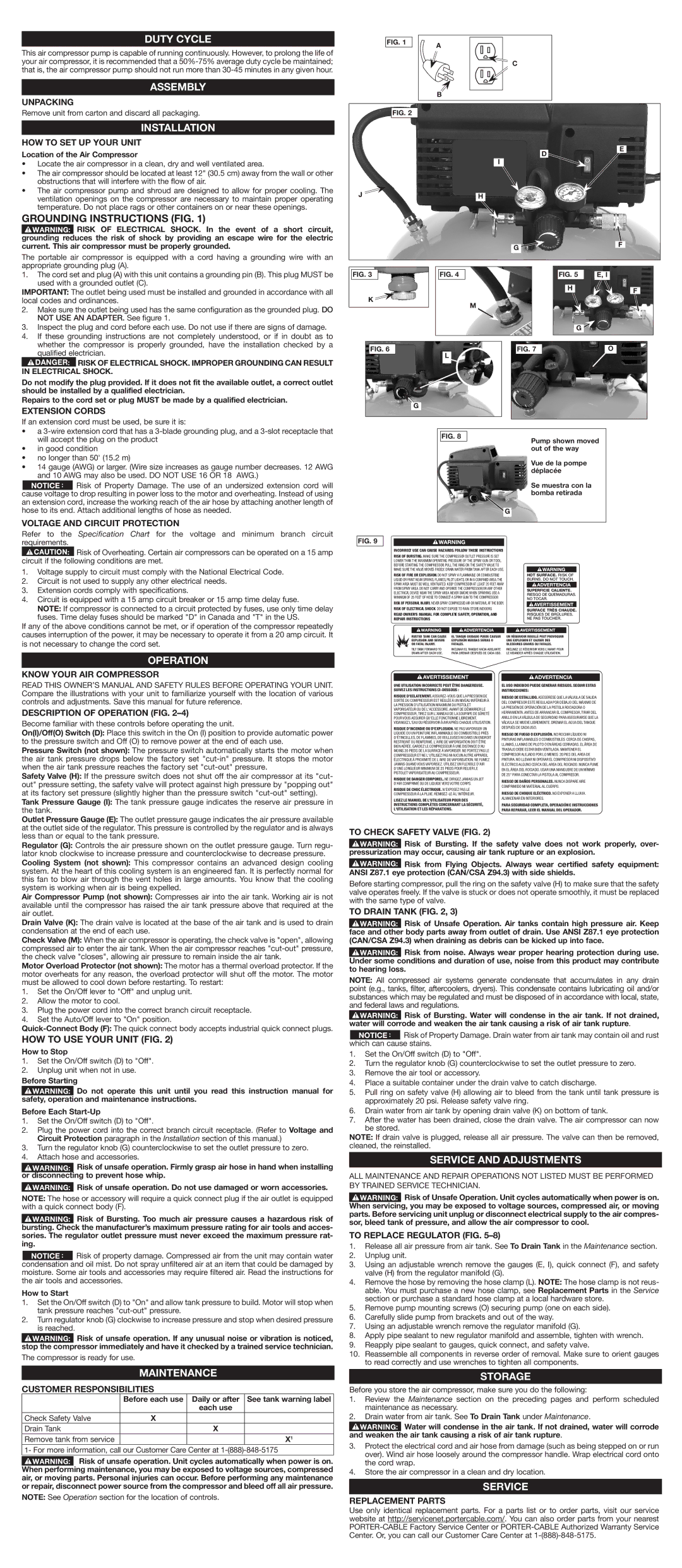

GROUNDING INSTRUCTIONS (FIG. 1)

RISK OF ELECTRICAL SHOCK. In the event of a short circuit, grounding reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded.

RISK OF ELECTRICAL SHOCK. In the event of a short circuit, grounding reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded.

The portable air compressor is equipped with a cord having a grounding wire with an appropriate grounding plug (A).

1.The cord set and plug (A) with this unit contains a grounding pin (B). This plug MUST be used with a grounded outlet (C).

IMPORTANT: The outlet being used must be installed and grounded in accordance with all local codes and ordinances.

2.Make sure the outlet being used has the same configuration as the grounded plug. DO NOT USE AN ADAPTER. See figure 1.

3.Inspect the plug and cord before each use. Do not use if there are signs of damage.

4.If these grounding instructions are not completely understood, or if in doubt as to whether the compressor is properly grounded, have the installation checked by a qualified electrician.

RISK OF ELECTRICAL SHOCK. IMPROPER GROUNDING CAN RESULT IN ELECTRICAL SHOCK.

RISK OF ELECTRICAL SHOCK. IMPROPER GROUNDING CAN RESULT IN ELECTRICAL SHOCK.

Do not modify the plug provided. If it does not fit the available outlet, a correct outlet should be installed by a qualified electrician.

Repairs to the cord set or plug MUST be made by a qualified electrician.

EXTENSION CORDS

If an extension cord must be used, be sure it is:

•a 3-wire extension cord that has a 3-blade grounding plug, and a 3‑slot receptacle that will accept the plug on the product

•in good condition

•no longer than 50' (15.2 m)

•14 gauge (AWG) or larger. (Wire size increases as gauge number decreases. 12 AWG and 10 AWG may also be used. DO NOT USE 16 OR 18 AWG.)

Risk of Property Damage. The use of an undersized extension cord will cause voltage to drop resulting in power loss to the motor and overheating. Instead of using an extension cord, increase the working reach of the air hose by attaching another length of hose to its end. Attach additional lengths of hose as needed.

Risk of Property Damage. The use of an undersized extension cord will cause voltage to drop resulting in power loss to the motor and overheating. Instead of using an extension cord, increase the working reach of the air hose by attaching another length of hose to its end. Attach additional lengths of hose as needed.

VOLTAGE AND CIRCUIT PROTECTION

Refer to the Specification Chart for the voltage and minimum branch circuit requirements.

Risk of Overheating. Certain air compressors can be operated on a 15 amp circuit if the following conditions are met.

Risk of Overheating. Certain air compressors can be operated on a 15 amp circuit if the following conditions are met.

1.Voltage supply to circuit must comply with the National Electrical Code.

2.Circuit is not used to supply any other electrical needs.

3.Extension cords comply with specifications.

4.Circuit is equipped with a 15 amp circuit breaker or 15 amp time delay fuse.

NOTE: If compressor is connected to a circuit protected by fuses, use only time delay fuses. Time delay fuses should be marked "D" in Canada and "T" in the US.

If any of the above conditions cannot be met, or if operation of the compressor repeatedly causes interruption of the power, it may be necessary to operate it from a 20 amp circuit. It

is not necessary to change the cord set.

OPERATION

KNOW YOUR AIR COMPRESSOR

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference.

DESCRIPTION OF OPERATION (FIG. 2–4)

Become familiar with these controls before operating the unit.

On(I)/Off(O) Switch (D): Place this switch in the On (I) position to provide automatic power to the pressure switch and Off (O) to remove power at the end of each use.

Pressure Switch (not shown): The pressure switch automatically starts the motor when the air tank pressure drops below the factory set "cut-in" pressure. It stops the motor when the air tank pressure reaches the factory set "cut-out" pressure.

Safety Valve (H): If the pressure switch does not shut off the air compressor at its "cut- out" pressure setting, the safety valve will protect against high pressure by "popping out" at its factory set pressure (slightly higher than the pressure switch "cut-out" setting).

Tank Pressure Gauge (I): The tank pressure gauge indicates the reserve air pressure in the tank.

Outlet Pressure Gauge (E): The outlet pressure gauge indicates the air pressure available at the outlet side of the regulator. This pressure is controlled by the regulator and is always less than or equal to the tank pressure.

Regulator (G): Controls the air pressure shown on the outlet pressure gauge. Turn regu- lator knob clockwise to increase pressure and counterclockwise to decrease pressure. Cooling System (not shown): This compressor contains an advanced design cooling system. At the heart of this cooling system is an engineered fan. It is perfectly normal for this fan to blow air through the vent holes in large amounts. You know that the cooling system is working when air is being expelled.

Air Compressor Pump (not shown): Compresses air into the air tank. Working air is not available until the compressor has raised the air tank pressure above that required at the air outlet.

Drain Valve (K): The drain valve is located at the base of the air tank and is used to drain condensation at the end of each use.

Check Valve (M): When the air compressor is operating, the check valve is "open", allowing compressed air to enter the air tank. When the air compressor reaches "cut-out" pressure, the check valve "closes", allowing air pressure to remain inside the air tank.

Motor Overload Protector (not shown): The motor has a thermal overload protector. If the motor overheats for any reason, the overload protector will shut off the motor. The motor must be allowed to cool down before restarting. To restart:

1.Set the On/Off lever to "Off" and unplug unit.

2.Allow the motor to cool.

3.Plug the power cord into the correct branch circuit receptacle.

4.Set the Auto/Off lever to "On" position.

Quick-Connect Body (F): The quick connect body accepts industrial quick connect plugs.

HOW TO USE YOUR UNIT (FIG. 2)

How to Stop

1.Set the On/Off switch (D) to "Off".

2.Unplug unit when not in use.

Before Starting

Do not operate this unit until you read this instruction manual for safety, operation and maintenance instructions.

Do not operate this unit until you read this instruction manual for safety, operation and maintenance instructions.

Before Each Start-Up

1.Set the On/Off switch (D) to "Off".

2.Plug the power cord into the correct branch circuit receptacle. (Refer to Voltage and Circuit Protection paragraph in the Installation section of this manual.)

3.Turn the regulator knob (G) counterclockwise to set the outlet pressure to zero.

4.Attach hose and accessories.

Risk of unsafe operation. Firmly grasp air hose in hand when installing or disconnecting to prevent hose whip.

Risk of unsafe operation. Firmly grasp air hose in hand when installing or disconnecting to prevent hose whip.

Risk of unsafe operation. Do not use damaged or worn accessories.

Risk of unsafe operation. Do not use damaged or worn accessories.

NOTE: The hose or accessory will require a quick connect plug if the air outlet is equipped with a quick connect body (F).

Risk of Bursting. Too much air pressure causes a hazardous risk of bursting. Check the manufacturer’s maximum pressure rating for air tools and acces- sories. The regulator outlet pressure must never exceed the maximum pressure rat- ing.

Risk of Bursting. Too much air pressure causes a hazardous risk of bursting. Check the manufacturer’s maximum pressure rating for air tools and acces- sories. The regulator outlet pressure must never exceed the maximum pressure rat- ing.

Risk of property damage. Compressed air from the unit may contain water condensation and oil mist. Do not spray unfiltered air at an item that could be damaged by moisture. Some air tools and accessories may require filtered air. Read the instructions for the air tools and accessories.

Risk of property damage. Compressed air from the unit may contain water condensation and oil mist. Do not spray unfiltered air at an item that could be damaged by moisture. Some air tools and accessories may require filtered air. Read the instructions for the air tools and accessories.

How to Start

1.Set the On/Off switch (D) to "On" and allow tank pressure to build. Motor will stop when tank pressure reaches "cut-out" pressure.

2.Turn regulator knob (G) clockwise to increase pressure and stop when desired pressure is reached.

Risk of unsafe operation. If any unusual noise or vibration is noticed, stop the compressor immediately and have it checked by a trained service technician.

Risk of unsafe operation. If any unusual noise or vibration is noticed, stop the compressor immediately and have it checked by a trained service technician.

The compressor is ready for use.

| MAINTENANCE |

CUSTOMER RESPONSIBILITIES |

| Before each use | Daily or after | See tank warning label |

| | each use | |

Check Safety Valve | X | | |

Drain Tank | | X | |

Remove tank from service | | | X1 |

1- For more information, call our Customer Care Center at 1-(888)-848-5175 |

Risk of unsafe operation. Unit cycles automatically when power is on. When performing maintenance, you may be exposed to voltage sources, compressed air, or moving parts. Personal injuries can occur. Before performing any maintenance or repair, disconnect power source from the compressor and bleed off all air pressure.

Risk of unsafe operation. Unit cycles automatically when power is on. When performing maintenance, you may be exposed to voltage sources, compressed air, or moving parts. Personal injuries can occur. Before performing any maintenance or repair, disconnect power source from the compressor and bleed off all air pressure.

NOTE: See Operation section for the location of controls.

C

C

B

FIG. 2

G  F

F

| | | | | | | | | | | | | | | | | | | | | | | | |

| FIG. 3 | | | | | FIG. 4 | | | | | | | | FIG. 5 | E, I | |

| | | | | | | | | | | | | | | | | | | | H | | | F | |

| | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | K | | | | | | M | | | | | | | | |

| | | | | | | | | | | | | | | | G | | | | |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

| | | | FIG. 6 | | | | | | | | | | FIG. 7 | | | | | O | | |

| | | | | | | | | | | L | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

G

| | | | | | | | |

| | | | FIG. 8 | | Pump shown moved |

| | | | | | | |

| | | | | | | | out of the way |

| | | | | | | | Vue de la pompe |

| | | | | | | | déplacée |

| | | | | | | | Se muestra con la |

| | | | | | | | bomba retirada |

| | | | | | | | G |

| | | | | | | | |

| | | | | | | |

FIG. 9 | | | | | | | | |

| | | | | | |

INCORRECT USE CAN CAUSE HAZARDS. FOLLOW THESE INSTRUCTIONS: | | | | |

RISK OF BURSTING. MAKE SURE THE COMPRESSOR OUTLET PRESSURE IS SET | | | | |

LOWER THAN THE MAXIMUM OPERATING PRESSURE OF THE SPRAY GUN OR TOOL. | | | | |

BEFORE STARTING THE COMPRESSOR, PULL THE RING ON THE SAFETY VALVE TO | | | | |

MAKE SURE THE VALVE MOVES FREELY. DRAIN WATER FROM TANK AFTER EACH USE. | | | | |

RISK OF FIRE OR EXPLOSION. DO NOT SPRAY A FLAMMABLE OR COMBUSTIBLE | | HOT SURFACE. RISK OF |

LIQUID OR PAINT NEAR SPARKS, FLAMES, PILOT LIGHTS, OR IN A CONFINED AREA. THE | | BURNS. DO NOT TOUCH. |

SPRAY AREA MUST BE WELL VENTILATED. KEEP COMPRESSOR AT LEAST 20 FEET AWAY | | | | |

FROM SPRAY AREA. DO NOT CARRY AND OPERATE THE COMPRESSOR, OR ANY OTHER | | SUPERFICIE CALIENTE. |

ELECTRICAL DEVICE NEAR THE SPRAY AREA. NEVER SMOKE WHEN SPRAYING. USE A | |

| RIESGO DE QUEMADURAS. |

MINIMUM OF 25 FEET OF HOSE TO CONNECT A SPRAY GUN TO THE COMPRESSOR. | |

| NO TOCAR. |

RISK OF PERSONAL INJURY. NEVER SPRAY COMPRESSED AIR OR MATERIAL AT THE BODY. | |

RISK OF ELECTRICAL SHOCK. DO NOT EXPOSE TO RAIN. STORE INDOORS. | | SURFACE TRÈS CHAUDE. |

| | | | | | |

READ OWNER'S MANUAL FOR COMPLETE SAFETY, OPERATION, AND | | RISQUES DE BRÛLURES. |

REPAIR INSTRUCTIONS. | | | | | NE PAS TOUCHER. |

| | | | | | | |

| | | | | | | | | |

RUSTED TANK CAN CAUSE | EL TANQUE OXIDADO PUEDE CAUSAR | UN RÈSERVOIR ROUILLÈ PEUT PROVOQUER |

EXPLOSION AND SEVERE | EXPLOSIÛN HERIDAS SERIAS O | UNE EXPLOSION ET CAUSER DES |

OR FATAL INJURY. | FATALES. | BLESSURES GRAVES OU FATALES. |

TILT TANK FORWARD TO | INCLINAR EL TANQUE HACIA ADELANTE | INCLINEZ LE RÈSERVOIR VERS L'AVANT POUR |

DRAIN AFTER EACH USE. | PARA DRENAR DESPUÈS DE CADA USO. | LE VIDANDER APRËS CHAQUE UTILISATION. |

| UNE UTILISATION INCORRECTE PEUT ÊTRE DANGEREUSE. | EL USO INDEBIDO PUEDE GENERAR RIESGOS. SEGUIR ESTAS |

| SUIVEZ LES INSTRUCTIONS CI-DESSOUS : | INSTRUCCIONES: |

| RISQUE D'ECLATEMENT. ASSUREZ-VOUS QUE LA PRESSION DE | RIESGO DE ESTALLIDO. ASEGÚRESE QUE LA VÁLVULA DE SALIDA |

| SORTIE DU COMPRESSEUR EST RÉGLÉE À UN NIVEAU INFÉRIEUR À |

| DEL COMPRESOR ESTE REGULADA POR DEBAJO DEL MÁXIMO DE |

| LA PRESSION D'UTILISATION MAXIMUM DU PISTOLET |

| LA PRESIÓN DE OPERACIÓN DE LA PISTOLA ROCIADORA O |

| VAPORISATEUR OU DE L'ACCESSOIRE. AVANT DE DÉMARRER LE |

| HERRAMIENTA. ANTES DE ARRANCAR EL COMPRESOR, TIRAR DEL |

| COMPRESSEUR, TIREZ SUR L'ANNEAU DE LA SOUPAPE DE SÛRETÉ |

| ANILLO EN LA VÁLBULA DE SEGURIDAD PARA ASEGURARSE QUE LA |

| POUR VOUS ASSURER QU'ELLE FONCTIONNE LIBREMENT. |

| VIDANGEZ L'EAU DU RÉSERVOIR À AIR APRÈS CHAQUE UTILISATION. | VÁLVULA SE MUEVE LIBREMENTE. DRENAR EL AGUA DEL TANQUE |

| RISQUE D'INCENDIE OU D'EXPLOSION. NE PAS VAPORISER UN | DESPUÉS DE CADA USO. |

| LIQUIDE OU UN PEINTURE INFLAMMABLE OU COMBUSTIBLE PRÈS | RIESGO DE FUEGO O EXPLOSIÓN. NO ROCIAR LÍQUIDO NI |

| D'ÉTINCELLES, DE FLAMMES, DE VEILLEUSES NI DANS UN ENDROIT | PINTURAS INFLAMABLES O COMBUSTIBLES CERCA DE CHISPAS, |

| RESTREINT OU RENFERMÉ. L'AIRE DE VAPORISATION DOIT ÊTRE |

| LLAMAS, LLAMAS DE PILOTO O EN ÁREAS CERRADAS. EL ÂREA DE |

| BIEN AÉRÉE. GARDEZ LE COMPRESSEUR À UNE DISTANCE D'AU |

| TRABAJO DEBE ESTAR BIEN VENTILADA. MANTENER EL |

| MOINS 20 PIEDS DE LA SURFACE À VAPORISER. NE PORTEZ PAS LE |

| COMPRESOR ALEJADO POR LO MENOS 20 PIES DEL AREA DE |

| COMPRESSEUR ET NE L'UTILISEZ PAS NI AUCUN AUTRE APPAREIL |

| ÉLECTRIQUE À PROXIMITÉ DE L'AIRE DE VAPORISATION. NE FUMEZ | PINTURA. NO LLEVAR NI OPERAR EL COMPRESOR NI DISPOSITIVO |

| JAMAIS QUAND VOUS VAPORISEZ. UTILISEZ UN FLEXIBLE D'AIR | ELÉCTRICO ALGUNO CERCA DEL AREA DEL ROCIADO. NUNCA FUME |

| D'UNE LONGUEUR MINIMUM DE 25 PIEDS POUR RELIER LE | EN EL ÁREA DEL ROCIADO. USAR UNA MANGUERE DE UN MÍNIMO |

| PISTOLET VAPORISATEUR AU COMPRESSEUR. |

| DE 25" PARA CONECTAR LA PISTOLA AL COMPRESOR. |

| RISQUE DE DANGER CORPOREL. NE DIRIGEZ JAMAIS UN JET |

| RIESGO DE DAÑOS PERSONALES. NUNCA DISPARE AIRE |

| D'AIR COMPRIMÉ OU DE LIQUIDE VERS VOTRE CORPS. |

| COMPRIMIDO MI MATERIAL AL CUERPO. |

| RISQUE DE CHOC ÉLECTRIQUE. N'EXPOSEZ PAS LE |

| RIESGO DE CHOQUE ELÉCTRICO. NO EXPONER A LLUVIA. |

| COMPRESSEUR À LA PLUIE. REMISEZ-LE À L'INTÉRIEUR. |

| LISEZ LE MANUEL DE L'UTILISATEUR POUR DES | ALMACENAR EN INTERIORES. |

| |

| INSTRUCTIONS COMPLÈTES CONCERNANT LA SÉCURITÉ, | PARA SEGURIDAD COMPLETA, OPERACIÓN E INSTRUCCIONES |

| L'UTILISATION ET LES RÉPARATIONS. | PARA REPARAR, LEER EL MANUAL DEL OPERADOR. |

TO CHECK SAFETY VALVE (FIG. 2)

Risk of Bursting. If the safety valve does not work properly, over- pressurization may occur, causing air tank rupture or an explosion.

Risk of Bursting. If the safety valve does not work properly, over- pressurization may occur, causing air tank rupture or an explosion.

Risk from Flying Objects. Always wear certified safety equipment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side shields.

Risk from Flying Objects. Always wear certified safety equipment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side shields.

Before starting compressor, pull the ring on the safety valve (H) to make sure that the safety valve operates freely. If the valve is stuck or does not operate smoothly, it must be replaced with the same type of valve.

TO DRAIN TANK (FIG. 2, 3)

Risk of Unsafe Operation. Air tanks contain high pressure air. Keep face and other body parts away from outlet of drain. Use ANSI Z87.1 eye protection (CAN/CSA Z94.3) when draining as debris can be kicked up into face.

Risk of Unsafe Operation. Air tanks contain high pressure air. Keep face and other body parts away from outlet of drain. Use ANSI Z87.1 eye protection (CAN/CSA Z94.3) when draining as debris can be kicked up into face.

Risk from noise. Always wear proper hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

Risk from noise. Always wear proper hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

NOTE: All compressed air systems generate condensate that accumulates in any drain point (e.g., tanks, filter, aftercoolers, dryers). This condensate contains lubricating oil and/or substances which may be regulated and must be disposed of in accordance with local, state, and federal laws and regulations.

Risk of Bursting. Water will condense in the air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

Risk of Bursting. Water will condense in the air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

Risk of Property Damage. Drain water from air tank may contain oil and rust which can cause stains.

Risk of Property Damage. Drain water from air tank may contain oil and rust which can cause stains.

1.Set the On/Off switch (D) to "Off".

2.Turn the regulator knob (G) counterclockwise to set the outlet pressure to zero.

3.Remove the air tool or accessory.

4.Place a suitable container under the drain valve to catch discharge.

5.Pull ring on safety valve (H) allowing air to bleed from the tank until tank pressure is approximately 20 psi. Release safety valve ring.

6.Drain water from air tank by opening drain valve (K) on bottom of tank.

7.After the water has been drained, close the drain valve. The air compressor can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be removed, cleaned, the reinstalled.

SERVICE AND ADJUSTMENTS

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE TECHNICIAN.

Risk of Unsafe Operation. Unit cycles automatically when power is on. When servicing, you may be exposed to voltage sources, compressed air, or moving parts. Before servicing unit unplug or disconnect electrical supply to the air compres- sor, bleed tank of pressure, and allow the air compressor to cool.

Risk of Unsafe Operation. Unit cycles automatically when power is on. When servicing, you may be exposed to voltage sources, compressed air, or moving parts. Before servicing unit unplug or disconnect electrical supply to the air compres- sor, bleed tank of pressure, and allow the air compressor to cool.

TO REPLACE REGULATOR (FIG. 5–8)

1.Release all air pressure from air tank. See To Drain Tank in the Maintenance section.

2.Unplug unit.

3.Using an adjustable wrench remove the gauges (E, I), quick connect (F), and safety valve (H) from the regulator manifold (G).

4.Remove the hose by removing the hose clamp (L). NOTE: The hose clamp is not reus- able. You must purchase a new hose clamp, see Replacement Parts in the Service section or purchase a standard hose clamp at a local hardware store.

5.Remove pump mounting screws (O) securing pump (one on each side).

6.Carefully slide pump from brackets and out of the way.

7.Using an adjustable wrench remove the regulator manifold (G).

8.Apply pipe sealant to new regulator manifold and assemble, tighten with wrench.

9.Reapply pipe sealant to gauges, quick connect, and safety valve.

10.Reassemble all components in reverse order of removal. Make sure to orient gauges to read correctly and use wrenches to tighten all components.

STORAGE

Before you store the air compressor, make sure you do the following:

1.Review the Maintenance section on the preceding pages and perform scheduled maintenance as necessary.

2.Drain water from air tank. See To Drain Tank under Maintenance.

Water will condense in the air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

Water will condense in the air tank. If not drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

3.Protect the electrical cord and air hose from damage (such as being stepped on or run over). Wind air hose loosely around the compressor handle. Wrap electrical cord onto the cord wrap.

4.Store the air compressor in a clean and dry location.

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at http://servicenet.portercable.com/. You can also order parts from your nearest PORTER-CABLE Factory Service Center or PORTER-CABLE Authorized Warranty Service Center. Or, you can call our Customer Care Center at 1-(888)-848-5175.