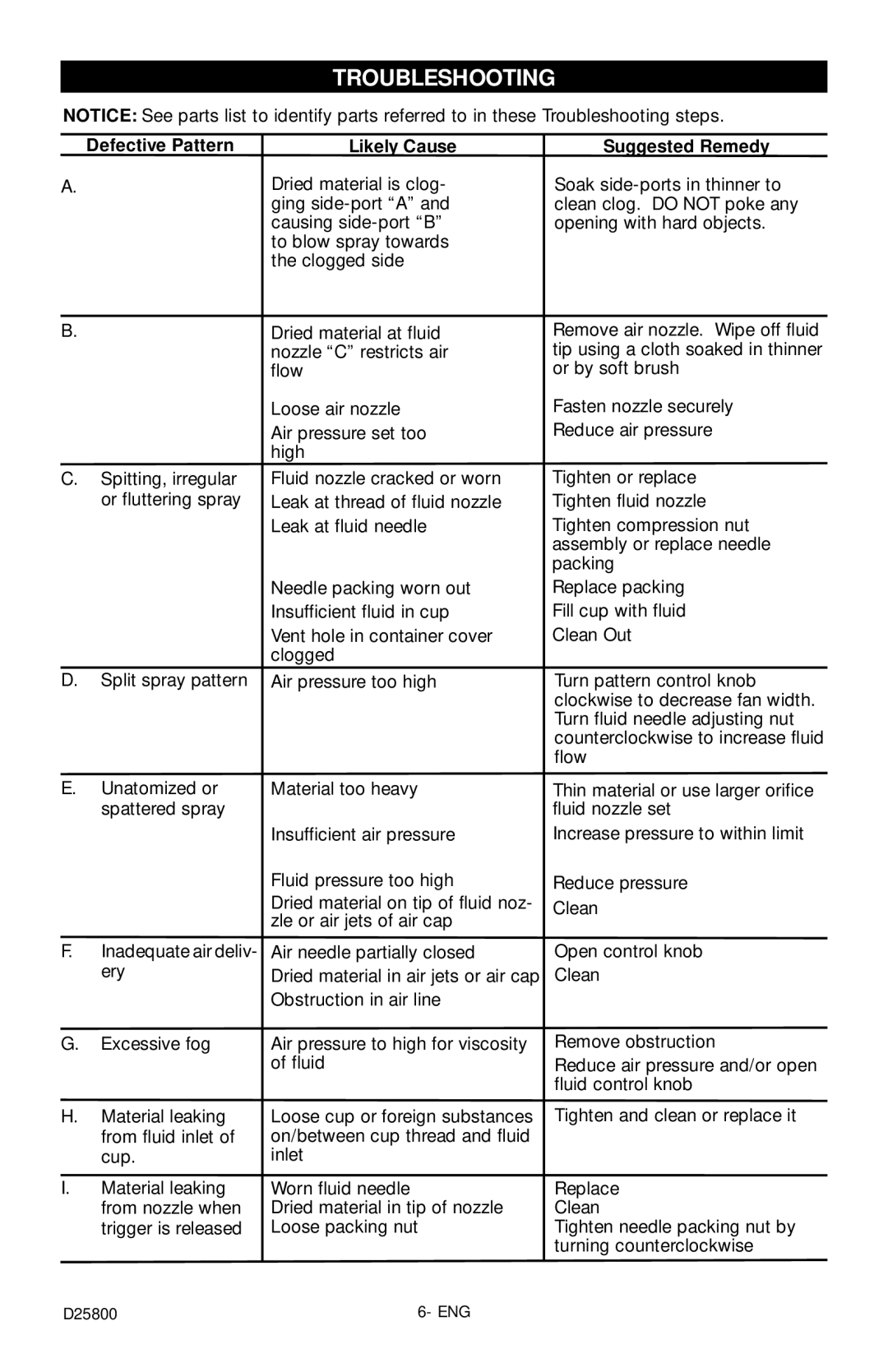

TROUBLESHOOTING

NOTICE: See parts list to identify parts referred to in these Troubleshooting steps.

| Defective Pattern | Likely Cause | Suggested Remedy |

A. |

| Dried material is clog- | Soak |

|

| ging | clean clog. DO NOT poke any |

|

| causing | opening with hard objects. |

|

| to blow spray towards |

|

|

| the clogged side |

|

|

|

|

|

B. |

| Dried material at fluid | Remove air nozzle. Wipe off fluid |

|

| nozzle “C” restricts air | tip using a cloth soaked in thinner |

|

| flow | or by soft brush |

|

| Loose air nozzle | Fasten nozzle securely |

|

| Air pressure set too | Reduce air pressure |

|

| high |

|

C. | Spitting, irregular | Fluid nozzle cracked or worn | Tighten or replace |

| or fluttering spray | Leak at thread of fluid nozzle | Tighten fluid nozzle |

|

| Leak at fluid needle | Tighten compression nut |

|

|

| assembly or replace needle |

|

|

| packing |

|

| Needle packing worn out | Replace packing |

|

| Insufficient fluid in cup | Fill cup with fluid |

|

| Vent hole in container cover | Clean Out |

|

| clogged |

|

D. | Split spray pattern | Air pressure too high | Turn pattern control knob |

|

|

| clockwise to decrease fan width. |

|

|

| Turn fluid needle adjusting nut |

|

|

| counterclockwise to increase fluid |

|

|

| flow |

E. | Unatomized or | Material too heavy | Thin material or use larger orifice |

| spattered spray |

| fluid nozzle set |

|

| Insufficient air pressure | Increase pressure to within limit |

|

| Fluid pressure too high | Reduce pressure |

|

| Dried material on tip of fluid noz- | Clean |

|

| zle or air jets of air cap |

|

F. Inadequate air deliv- | Air needle partially closed | Open control knob | |

| ery | Dried material in air jets or air cap | Clean |

|

| Obstruction in air line |

|

G. | Excessive fog | Air pressure to high for viscosity | Remove obstruction |

|

| of fluid | Reduce air pressure and/or open |

|

|

| fluid control knob |

H. | Material leaking | Loose cup or foreign substances | Tighten and clean or replace it |

| from fluid inlet of | on/between cup thread and fluid |

|

| cup. | inlet |

|

I. | Material leaking | Worn fluid needle | Replace |

| from nozzle when | Dried material in tip of nozzle | Clean |

| trigger is released | Loose packing nut | Tighten needle packing nut by |

|

|

| turning counterclockwise |

|

|

|

|

D25800 | 6- ENG |