| SPECIFICATIONS |

Strokes Per Minute | 5,000 |

Maximum Working Pressure | 90 PSI |

Blade Type | 32 teeth/24 teeth |

Air Inlet | 1/4" NPT |

Recommended Hose Size | 3/8" I.D. |

Air Consumption @ 90 PSI | 2.0 SCFM |

|

|

| ASSEMBLY |

Accessories Required |

|

IMPORTANT: Line pressure or hose inside diameter should be increased to compensate for unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8” I.D. and fittings should have 1/4” NPT thread.

OPERATION

Operation

Before each use:

●Drain water from air compressor tank and condensation from air lines. See air compressor’s operators manual.

Disconnect the saw from the air supply before lubricating or changing blades.

●Lubricate tool, see “Maintenance” section in this manual.

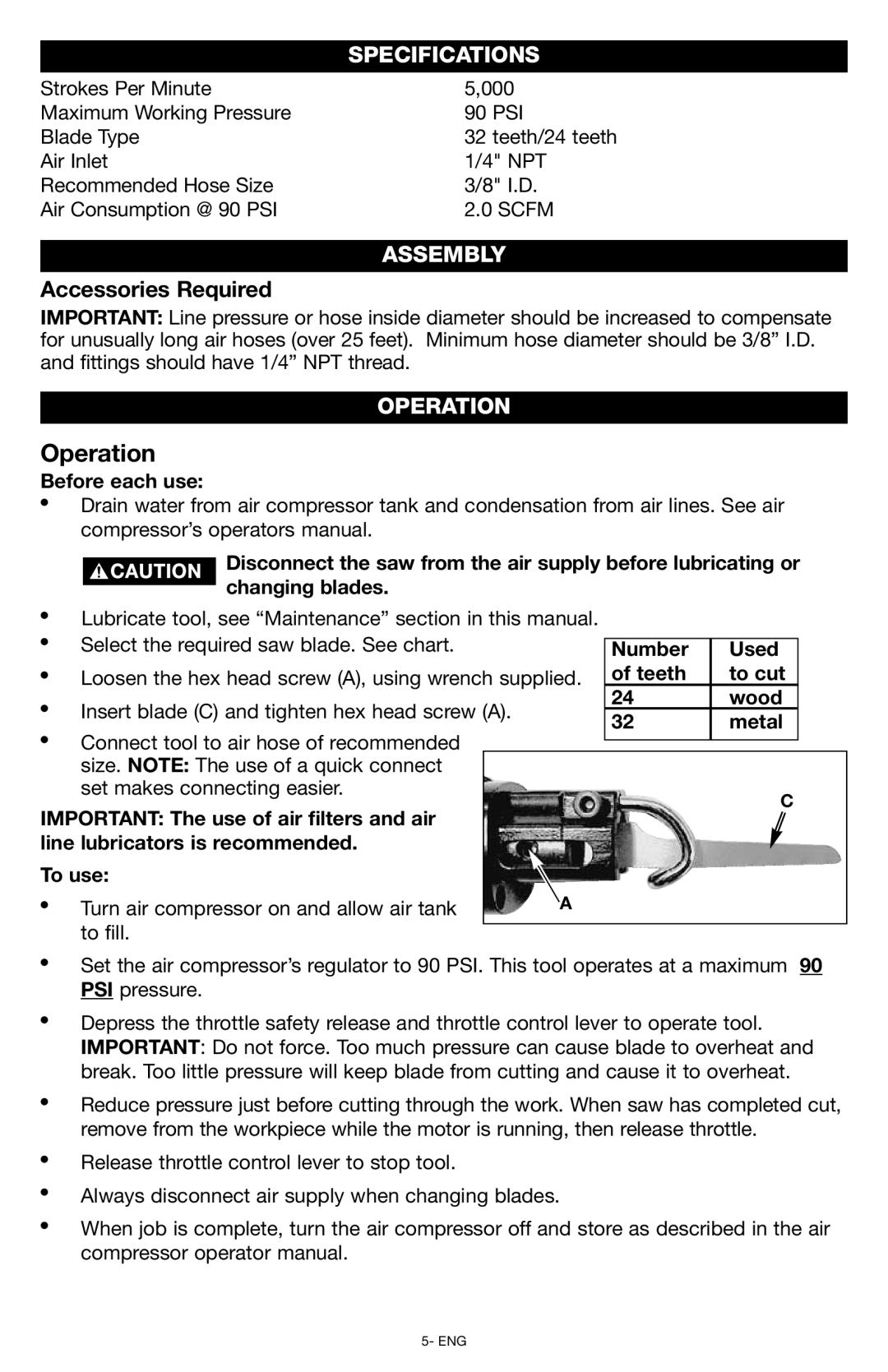

● | Select the required saw blade. See chart. |

| Number | Used |

| |

|

|

| ||||

● | Loosen the hex head screw (A), using wrench supplied. | of teeth | to cut |

| ||

|

|

|

|

|

|

|

● | Insert blade (C) and tighten hex head screw (A). |

| 24 | wood |

| |

| 32 | metal |

| |||

|

|

| ||||

| Connect tool to air hose of recommended |

|

| |||

● |

|

|

|

| ||

|

|

|

| |||

|

|

|

|

| ||

| size. NOTE: The use of a quick connect |

|

|

|

|

|

| set makes connecting easier. |

|

|

| C |

|

IMPORTANT: The use of air filters and air |

|

|

|

| ||

|

|

|

|

| ||

line lubricators is recommended. |

|

|

|

|

| |

To use: |

|

|

|

|

| |

● | Turn air compressor on and allow air tank |

| A |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

to fill.

●

●

●

●

●

●

Set the air compressor’s regulator to 90 PSI. This tool operates at a maximum 90 PSI pressure.

Depress the throttle safety release and throttle control lever to operate tool. IMPORTANT: Do not force. Too much pressure can cause blade to overheat and break. Too little pressure will keep blade from cutting and cause it to overheat.

Reduce pressure just before cutting through the work. When saw has completed cut, remove from the workpiece while the motor is running, then release throttle.

Release throttle control lever to stop tool.

Always disconnect air supply when changing blades.

When job is complete, turn the air compressor off and store as described in the air compressor operator manual.

5- ENG