clearance will vary. This clearance can be observed from the offset pattern printed in bottom of self test.

Whenever the lower part of the long vertical lines is shifted horizontally away from the upper part by about one dot width, the offset value should be adjusted to move it back for decent print if

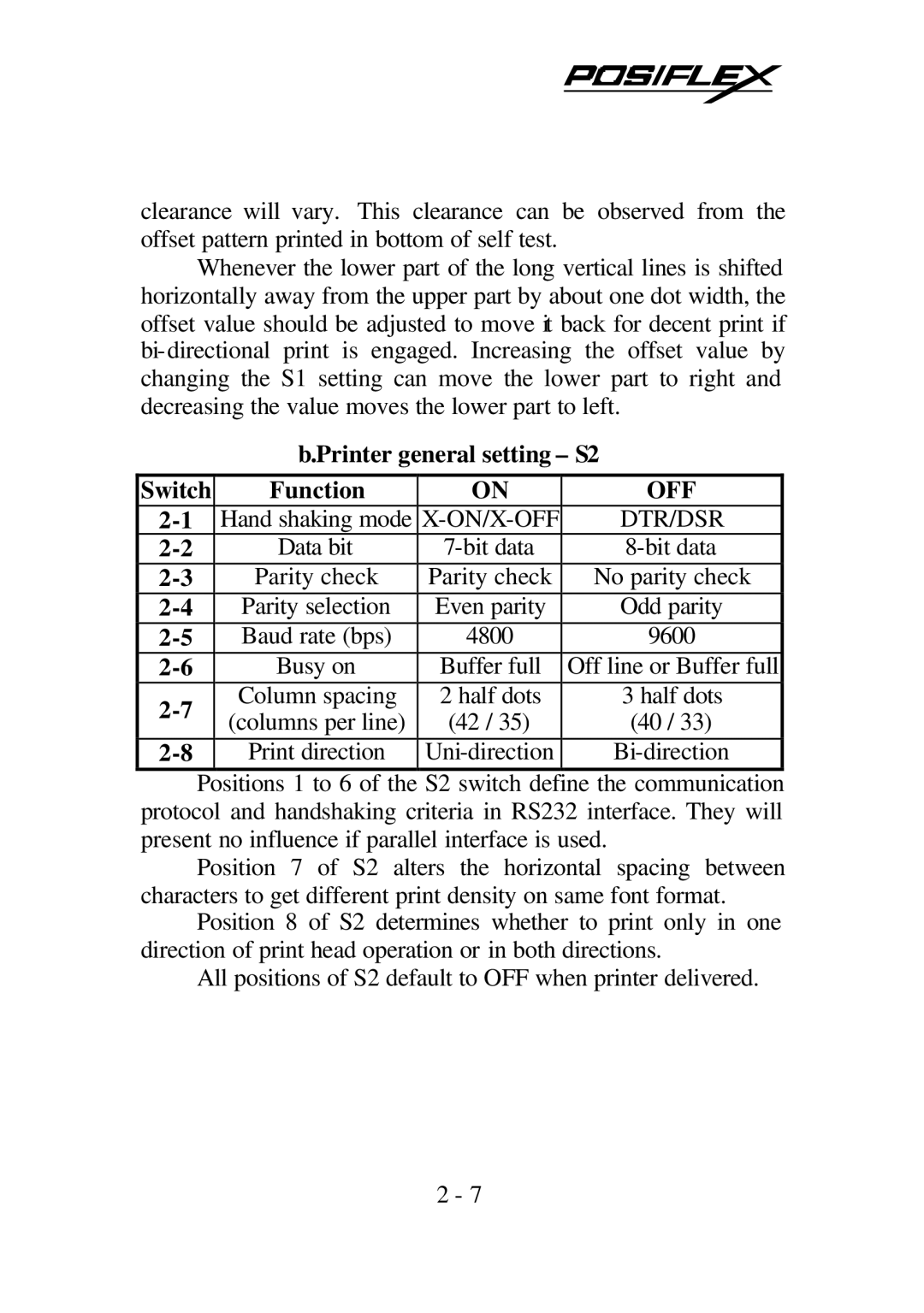

b.Printer general setting – S2

Switch | Function | ON | OFF | |

Hand shaking mode |

| DTR/DSR | ||

Data bit | ||||

Parity check | Parity check | No parity check | ||

Parity selection | Even parity | Odd parity | ||

Baud rate (bps) | 4800 | 9600 | ||

Busy on | Buffer full | Off line or Buffer full | ||

Column spacing | 2 half dots | 3 half dots | ||

(columns per line) | (42 / 35) | (40 / 33) | ||

| ||||

Print direction |

Positions 1 to 6 of the S2 switch define the communication protocol and handshaking criteria in RS232 interface. They will present no influence if parallel interface is used.

Position 7 of S2 alters the horizontal spacing between characters to get different print density on same font format.

Position 8 of S2 determines whether to print only in one direction of print head operation or in both directions.

All positions of S2 default to OFF when printer delivered.

3.Wall mount application

In wall mount application, the paper near end sensor will not have proper operation and it is suggested not to install it.

2 - 7