115156526 specifications

The Poulan 115156526 is a versatile chainsaw designed for both casual users and more experienced operators. This model is particularly noted for its blend of power, efficiency, and user-friendly features, making it a popular choice for tasks ranging from trimming branches to cutting firewood.One of the standout features of the Poulan 115156526 is its robust engine. Equipped with a 42cc, two-stroke engine, it provides ample power for tackling a variety of cutting jobs. This engine delivers a high power-to-weight ratio, ensuring that users can handle the tool with ease without compromising on performance. The chainsaw’s design emphasizes not only power but also fuel efficiency, allowing users to work longer without frequent refueling.

The bar length of the 115156526 typically measures around 16 inches, which strikes a balance between maneuverability and cutting capacity. This length is ideal for medium-sized trees and shrubs, making it a great tool for yard maintenance and landscaping tasks. Additionally, the chainsaw features a low-kickback chain, which enhances safety while providing smooth and efficient cutting.

Another notable aspect of the Poulan 115156526 is its starting technology. Equipped with an easier starting mechanism, this chainsaw often incorporates features such as an automatic primer bulb and easy-to-use recoil starter, making it simpler to start even for novice users. The anti-vibration system minimizes user fatigue during operation, allowing for prolonged use without discomfort.

Safety features are also critical for any chainsaw, and the Poulan 115156526 does not disappoint. The chainsaw includes a chain brake designed to stop the chain almost instantaneously in case of kickback. This feature is crucial for novice users who may not yet be fully accustomed to handling chainsaws.

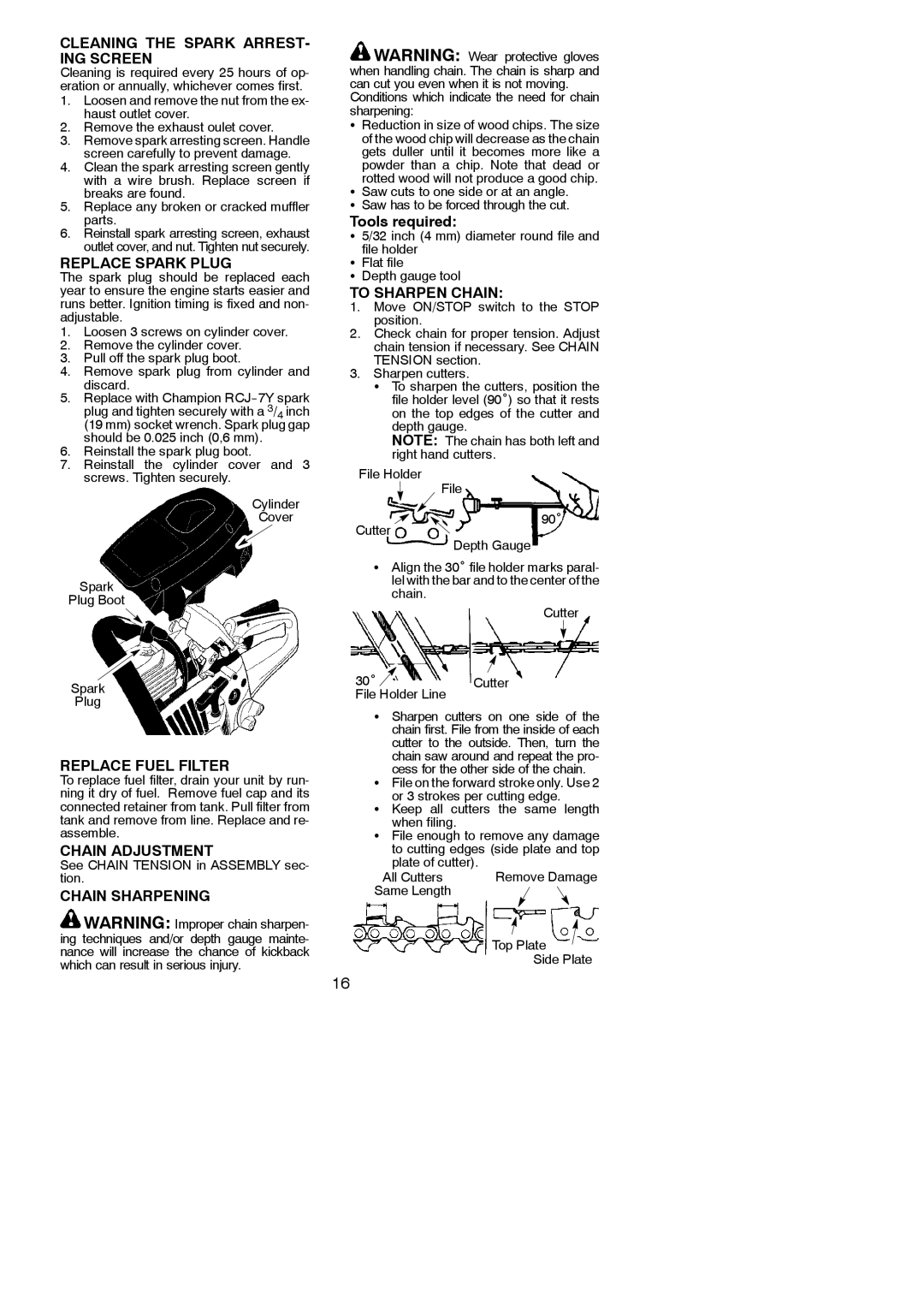

In terms of maintenance, the Poulan 115156526 is designed for ease of access to the air filter and spark plug, making routine upkeep more straightforward. Its removable side access chain tensioner allows for quick and hassle-free adjustments to the chain tension, which is vital for consistent cutting performance.

Overall, the Poulan 115156526 stands out for its combination of power, safety, and user-friendly innovation. Whether you are clearing your yard, maintaining trees, or preparing firewood, this chainsaw provides the reliability and efficiency needed to get the job done effectively.