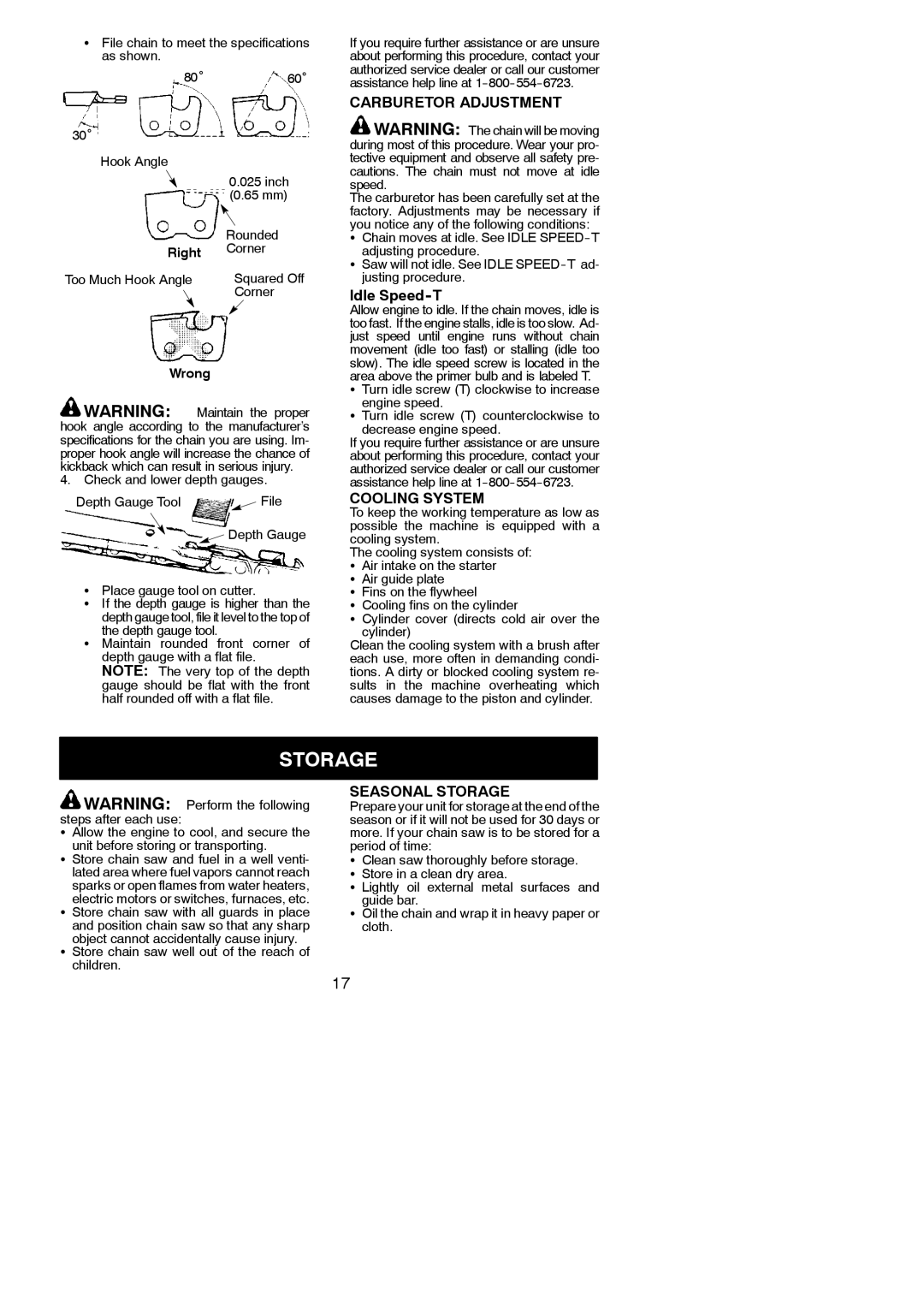

SFile chain to meet the specifications as shown.

| 80˚ | 60˚ |

30˚ |

|

|

Hook Angle |

|

|

|

| 0.025 inch |

|

| (0.65 mm) |

|

| Rounded |

Right | Corner | |

| ||

Too Much Hook Angle | Squared Off | |

|

| Corner |

Wrong |

| |

WARNING: | Maintain the proper | |

hook angle according to the manufacturer’s specifications for the chain you are using. Im- proper hook angle will increase the chance of kickback which can result in serious injury.

4. Check and lower depth gauges.

Depth Gauge Tool | File |

![]() Depth Gauge

Depth Gauge

SPlace gauge tool on cutter.

SIf the depth gauge is higher than the

depth gauge tool, file it level to the top of the depth gauge tool.

SMaintain rounded front corner of depth gauge with a flat file.

NOTE: The very top of the depth gauge should be flat with the front half rounded off with a flat file.

If you require further assistance or are unsure about performing this procedure, contact your authorized service dealer or call our customer assistance help line at

CARBURETOR ADJUSTMENT

![]() WARNING: The chain will be moving during most of this procedure. Wear your pro- tective equipment and observe all safety pre- cautions. The chain must not move at idle speed.

WARNING: The chain will be moving during most of this procedure. Wear your pro- tective equipment and observe all safety pre- cautions. The chain must not move at idle speed.

The carburetor has been carefully set at the factory. Adjustments may be necessary if you notice any of the following conditions:

SChain moves at idle. See IDLE

SSaw will not idle. See IDLE

Idle Speed-T

Allow engine to idle. If the chain moves, idle is too fast. If the engine stalls, idle is too slow. Ad- just speed until engine runs without chain movement (idle too fast) or stalling (idle too slow). The idle speed screw is located in the area above the primer bulb and is labeled T.

STurn idle screw (T) clockwise to increase

engine speed.

S Turn idle screw (T) counterclockwise to decrease engine speed.

If you require further assistance or are unsure about performing this procedure, contact your authorized service dealer or call our customer assistance help line at

COOLING SYSTEM

To keep the working temperature as low as possible the machine is equipped with a cooling system.

The cooling system consists of:

SAir intake on the starter S Air guide plate

S Fins on the flywheel

S Cooling fins on the cylinder

S Cylinder cover (directs cold air over the cylinder)

Clean the cooling system with a brush after each use, more often in demanding condi- tions. A dirty or blocked cooling system re- sults in the machine overheating which causes damage to the piston and cylinder.

STORAGE

![]() WARNING: Perform the following steps after each use:

WARNING: Perform the following steps after each use:

SAllow the engine to cool, and secure the unit before storing or transporting.

SStore chain saw and fuel in a well venti- lated area where fuel vapors cannot reach sparks or open flames from water heaters, electric motors or switches, furnaces, etc.

SStore chain saw with all guards in place

and position chain saw so that any sharp object cannot accidentally cause injury.

SStore chain saw well out of the reach of children.

SEASONAL STORAGE

Prepare your unit for storage at the end of the season or if it will not be used for 30 days or more. If your chain saw is to be stored for a period of time:

SClean saw thoroughly before storage. S Store in a clean dry area.

S Lightly oil external metal surfaces and guide bar.

S Oil the chain and wrap it in heavy paper or cloth.

17