General Operation

Always clamp the workpiece securely on a

6. If the saw binds and stalls, maintain |

a firm grip and release the trigger im- |

mediately. Hold the saw motionless in |

APPLICATIONS

saw horse or bench (Fig. 10). See “APPLICA- TIONS” for the correct way to support your work in different situations.

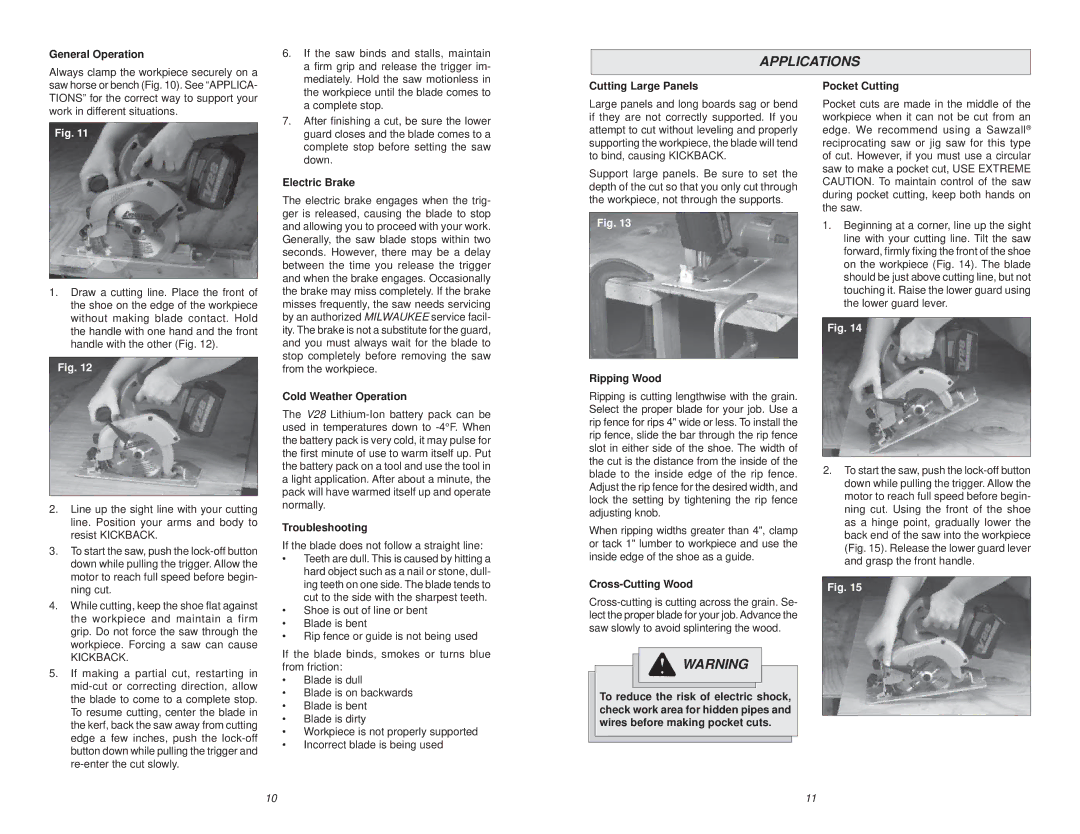

Fig. 11

1.Draw a cutting line. Place the front of the shoe on the edge of the workpiece without making blade contact. Hold the handle with one hand and the front handle with the other (Fig. 12).

Fig. 12

2.Line up the sight line with your cutting line. Position your arms and body to resist KICKBACK.

3.To start the saw, push the

4.While cutting, keep the shoe flat against the workpiece and maintain a firm grip. Do not force the saw through the workpiece. Forcing a saw can cause

KICKBACK.

5.If making a partial cut, restarting in

the workpiece until the blade comes to |

a complete stop. |

7. After finishing a cut, be sure the lower |

guard closes and the blade comes to a |

complete stop before setting the saw |

down. |

Electric Brake

The electric brake engages when the trig- ger is released, causing the blade to stop and allowing you to proceed with your work. Generally, the saw blade stops within two seconds. However, there may be a delay between the time you release the trigger and when the brake engages. Occasionally the brake may miss completely. If the brake misses frequently, the saw needs servicing by an authorized MILWAUKEE service facil- ity. The brake is not a substitute for the guard, and you must always wait for the blade to stop completely before removing the saw from the workpiece.

Cold Weather Operation

The V28

Troubleshooting

If the blade does not follow a straight line:

•Teeth are dull. This is caused by hitting a hard object such as a nail or stone, dull- ing teeth on one side. The blade tends to cut to the side with the sharpest teeth.

•Shoe is out of line or bent

•Blade is bent

•Rip fence or guide is not being used

If the blade binds, smokes or turns blue from friction:

•Blade is dull

•Blade is on backwards

•Blade is bent

•Blade is dirty

•Workpiece is not properly supported

•Incorrect blade is being used

Cutting Large Panels

Large panels and long boards sag or bend if they are not correctly supported. If you attempt to cut without leveling and properly supporting the workpiece, the blade will tend to bind, causing KICKBACK.

Support large panels. Be sure to set the depth of the cut so that you only cut through the workpiece, not through the supports.

Fig. 13

Ripping Wood

Ripping is cutting lengthwise with the grain. Select the proper blade for your job. Use a rip fence for rips 4" wide or less. To install the rip fence, slide the bar through the rip fence slot in either side of the shoe. The width of the cut is the distance from the inside of the blade to the inside edge of the rip fence. Adjust the rip fence for the desired width, and lock the setting by tightening the rip fence adjusting knob.

When ripping widths greater than 4", clamp or tack 1" lumber to workpiece and use the inside edge of the shoe as a guide.

Cross-Cutting Wood

![]() WARNING

WARNING

To reduce the risk of electric shock, check work area for hidden pipes and wires before making pocket cuts.

Pocket Cutting

Pocket cuts are made in the middle of the workpiece when it can not be cut from an edge. We recommend using a Sawzall® reciprocating saw or jig saw for this type of cut. However, if you must use a circular saw to make a pocket cut, USE EXTREME CAUTION. To maintain control of the saw during pocket cutting, keep both hands on the saw.

1.Beginning at a corner, line up the sight line with your cutting line. Tilt the saw forward, firmly fixing the front of the shoe on the workpiece (Fig. 14). The blade should be just above cutting line, but not touching it. Raise the lower guard using the lower guard lever.

Fig. 14

2.To start the saw, push the

Fig. 15

10 | 11 |