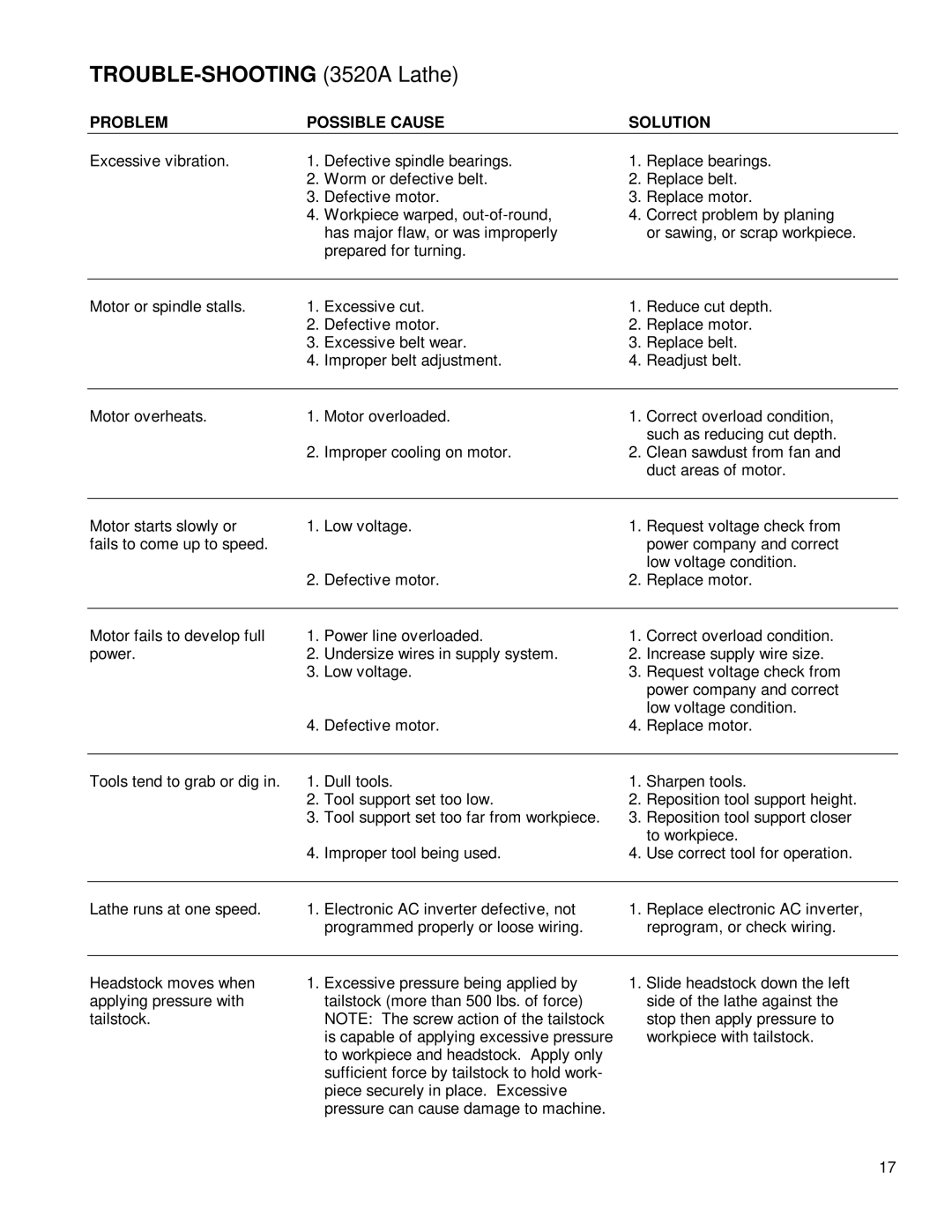

TROUBLE-SHOOTING (3520A Lathe)

PROBLEM | POSSIBLE CAUSE | SOLUTION | ||

Excessive vibration. | 1. Defective spindle bearings. | 1. | Replace bearings. | |

| 2. | Worm or defective belt. | 2. | Replace belt. |

| 3. | Defective motor. | 3. | Replace motor. |

| 4. | Workpiece warped, | 4. | Correct problem by planing |

|

| has major flaw, or was improperly |

| or sawing, or scrap workpiece. |

|

| prepared for turning. |

|

|

|

|

|

| |

Motor or spindle stalls. | 1. Excessive cut. | 1. | Reduce cut depth. | |

| 2. | Defective motor. | 2. | Replace motor. |

| 3. | Excessive belt wear. | 3. | Replace belt. |

| 4. | Improper belt adjustment. | 4. | Readjust belt. |

|

|

|

| |

Motor overheats. | 1. Motor overloaded. | 1. | Correct overload condition, | |

|

|

|

| such as reducing cut depth. |

| 2. | Improper cooling on motor. | 2. | Clean sawdust from fan and |

|

|

|

| duct areas of motor. |

|

|

|

| |

Motor starts slowly or | 1. Low voltage. | 1. | Request voltage check from | |

fails to come up to speed. |

|

|

| power company and correct |

|

|

|

| low voltage condition. |

| 2. | Defective motor. | 2. | Replace motor. |

|

|

|

| |

Motor fails to develop full | 1. Power line overloaded. | 1. | Correct overload condition. | |

power. | 2. Undersize wires in supply system. | 2. | Increase supply wire size. | |

| 3. | Low voltage. | 3. | Request voltage check from |

|

|

|

| power company and correct |

|

|

|

| low voltage condition. |

| 4. | Defective motor. | 4. | Replace motor. |

|

|

|

| |

Tools tend to grab or dig in. | 1. Dull tools. | 1. | Sharpen tools. | |

| 2. | Tool support set too low. | 2. | Reposition tool support height. |

| 3. | Tool support set too far from workpiece. | 3. | Reposition tool support closer |

|

|

|

| to workpiece. |

| 4. | Improper tool being used. | 4. | Use correct tool for operation. |

Lathe runs at one speed.

1.Electronic AC inverter defective, not programmed properly or loose wiring.

1.Replace electronic AC inverter, reprogram, or check wiring.

Headstock moves when | 1. Excessive pressure being applied by |

applying pressure with | tailstock (more than 500 lbs. of force) |

tailstock. | NOTE: The screw action of the tailstock |

| is capable of applying excessive pressure |

| to workpiece and headstock. Apply only |

| sufficient force by tailstock to hold work- |

| piece securely in place. Excessive |

| pressure can cause damage to machine. |

1.Slide headstock down the left side of the lathe against the stop then apply pressure to workpiece with tailstock.

17