4.Rotate workpiece by hand to check for proper clearance.

5.Start lathe at lowest speed and bring it up to the appropriate RPM for the size of stock used (refer to table on page 9).

CUTTING TECHNIQUES

ROUGHING OUT:

1.Begin with a large roughing gouge. Place the tool on the tool support with the heel of the tool on the surface to be cut.

2.Slowly and gently raise tool handle until cutting edge comes into contact with the workpiece.

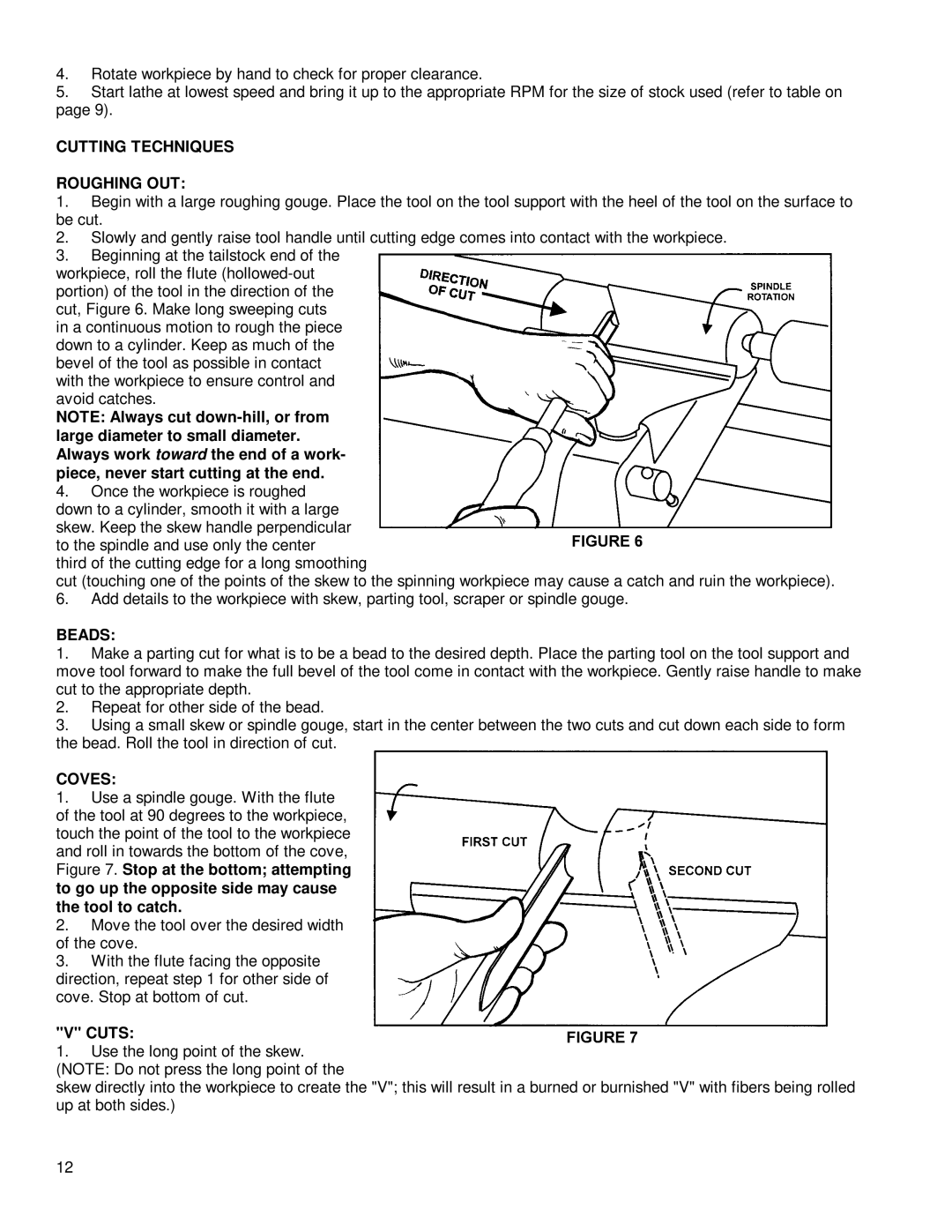

3.Beginning at the tailstock end of the

workpiece, roll the flute

NOTE: Always cut

4.Once the workpiece is roughed down to a cylinder, smooth it with a large skew. Keep the skew handle perpendicular to the spindle and use only the center

third of the cutting edge for a long smoothing

cut (touching one of the points of the skew to the spinning workpiece may cause a catch and ruin the workpiece).

6.Add details to the workpiece with skew, parting tool, scraper or spindle gouge.

BEADS:

1.Make a parting cut for what is to be a bead to the desired depth. Place the parting tool on the tool support and move tool forward to make the full bevel of the tool come in contact with the workpiece. Gently raise handle to make cut to the appropriate depth.

2.Repeat for other side of the bead.

3.Using a small skew or spindle gouge, start in the center between the two cuts and cut down each side to form the bead. Roll the tool in direction of cut.

COVES:

1.Use a spindle gouge. With the flute of the tool at 90 degrees to the workpiece, touch the point of the tool to the workpiece and roll in towards the bottom of the cove, Figure 7. Stop at the bottom; attempting to go up the opposite side may cause the tool to catch.

2.Move the tool over the desired width of the cove.

3.With the flute facing the opposite direction, repeat step 1 for other side of cove. Stop at bottom of cut.

"V" CUTS:

1.Use the long point of the skew. (NOTE: Do not press the long point of the

skew directly into the workpiece to create the "V"; this will result in a burned or burnished "V" with fibers being rolled up at both sides.)

12