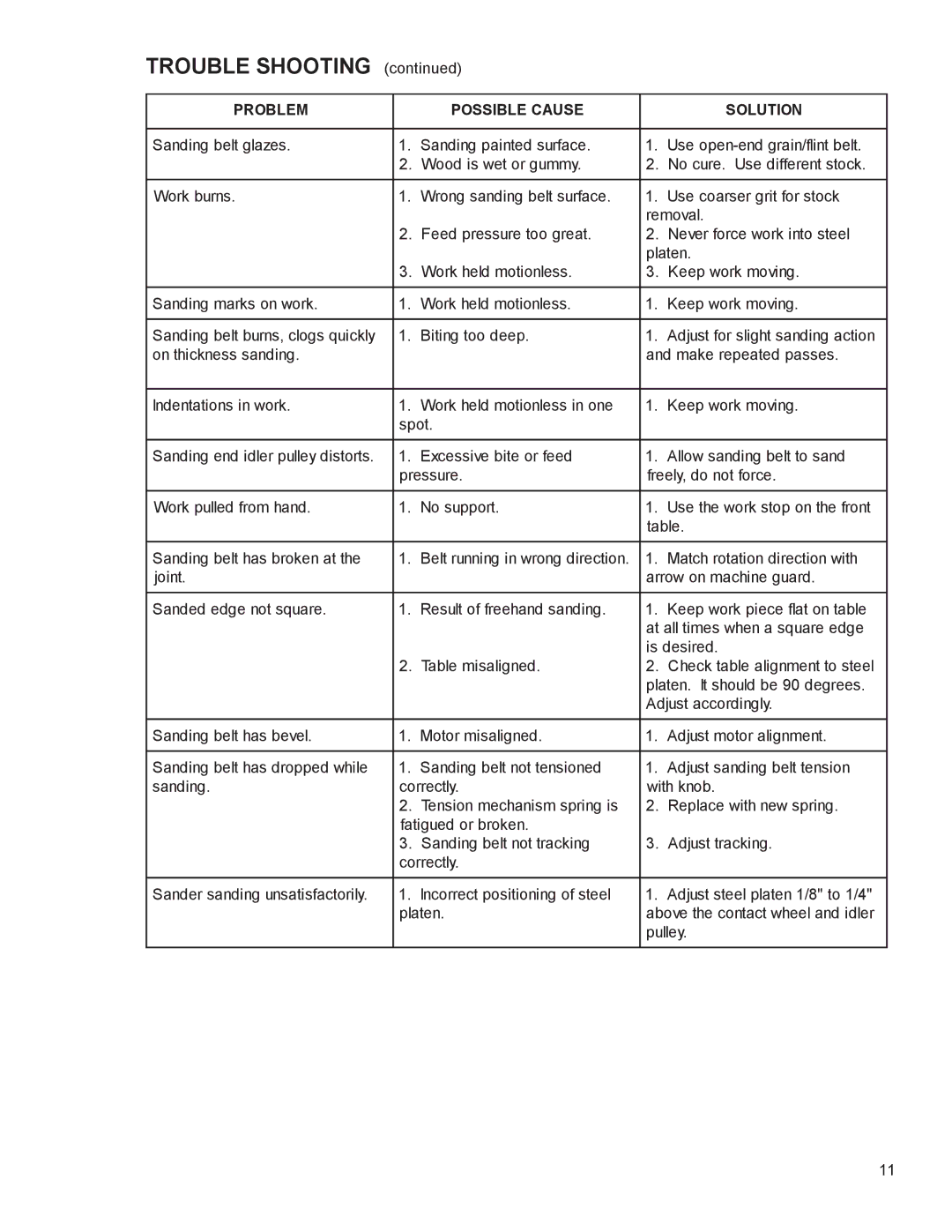

TROUBLE SHOOTING (continued)

PROBLEM |

| POSSIBLE CAUSE |

| SOLUTION |

|

|

|

|

|

Sanding belt glazes. | 1. | Sanding painted surface. | 1. | Use |

| 2. | Wood is wet or gummy. | 2. | No cure. Use different stock. |

|

|

|

|

|

Work burns. | 1. | Wrong sanding belt surface. | 1. | Use coarser grit for stock |

|

|

| removal. | |

| 2. | Feed pressure too great. | 2. | Never force work into steel |

|

|

| platen. | |

| 3. | Work held motionless. | 3. | Keep work moving. |

|

|

|

| |

Sanding marks on work. | 1. Work held motionless. | 1. | Keep work moving. | |

|

|

|

| |

Sanding belt burns, clogs quickly | 1. Biting too deep. | 1. | Adjust for slight sanding action | |

on thickness sanding. |

|

| and make repeated passes. | |

|

|

|

|

|

Indentations in work. | 1. | Work held motionless in one | 1. | Keep work moving. |

| spot. |

|

| |

|

|

|

|

|

Sanding end idler pulley distorts. | 1. | Excessive bite or feed | 1. | Allow sanding belt to sand |

| pressure. | freely, do not force. | ||

|

|

|

| |

Work pulled from hand. | 1. No support. | 1. | Use the work stop on the front | |

|

|

| table. | |

|

|

|

| |

Sanding belt has broken at the | 1. Belt running in wrong direction. | 1. | Match rotation direction with | |

joint. |

|

| arrow on machine guard. | |

|

|

|

|

|

Sanded edge not square. | 1. | Result of freehand sanding. | 1. | Keep work piece flat on table |

|

|

| at all times when a square edge | |

|

|

| is desired. | |

| 2. | Table misaligned. | 2. | Check table alignment to steel |

|

|

| platen. It should be 90 degrees. | |

|

|

| Adjust accordingly. | |

|

|

|

| |

Sanding belt has bevel. | 1. Motor misaligned. | 1. | Adjust motor alignment. | |

|

|

|

|

|

Sanding belt has dropped while | 1. | Sanding belt not tensioned | 1. | Adjust sanding belt tension |

sanding. | correctly. | with knob. | ||

| 2. | Tension mechanism spring is | 2. | Replace with new spring. |

| fatigued or broken. |

|

| |

| 3. | Sanding belt not tracking | 3. | Adjust tracking. |

| correctly. |

|

| |

|

|

|

|

|

Sander sanding unsatisfactorily. | 1. | Incorrect positioning of steel | 1. | Adjust steel platen 1/8" to 1/4" |

| platen. | above the contact wheel and idler | ||

|

|

| pulley. | |

|

|

|

|

|

11