MAINTENANCE

LUBRICATION

![]() CAUTION: Disconnect sander from power

CAUTION: Disconnect sander from power

source before performing maintenance. |

|

|

|

| ||||

Do not operate the sander until it is properly lubri- |

|

|

| |||||

cated. |

|

|

|

|

|

| ||

All ball bearings are sealed for life and do not require |

|

|

| |||||

lubrication. |

|

|

|

|

|

| ||

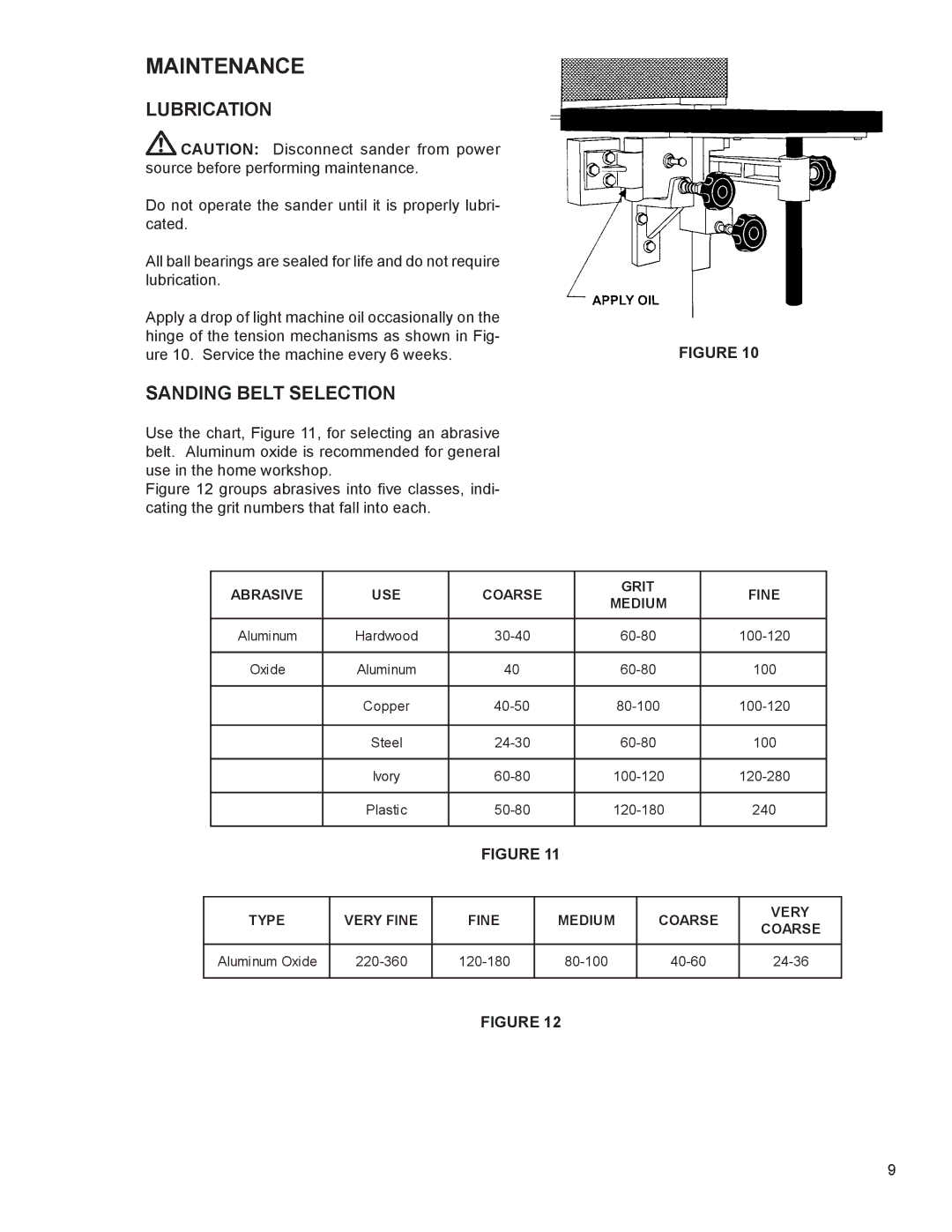

Apply a drop of light machine oil occasionally on the |

|

|

| |||||

hinge of the tension mechanisms as shown in Fig- |

| FIGURE 10 | ||||||

ure 10. Service the machine every 6 weeks. |

|

| ||||||

SANDING BELT SELECTION |

|

|

|

| ||||

Use the chart, Figure 11, for selecting an abrasive |

|

|

| |||||

belt. Aluminum oxide is recommended for general |

|

|

| |||||

use in the home workshop. |

|

|

|

|

|

| ||

Figure 12 groups abrasives into five classes, indi- |

|

|

| |||||

cating the grit numbers that fall into each. |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ABRASIVE |

| USE |

| COARSE | GRIT |

| FINE |

|

|

| MEDIUM |

| ||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| Aluminum |

| Hardwood |

|

| |||

|

|

|

|

|

|

|

|

|

| Oxide |

| Aluminum |

| 40 |

| 100 | |

|

|

|

|

|

|

|

|

|

|

|

| Copper |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| Steel |

|

| 100 | ||

|

|

|

|

|

|

|

|

|

|

|

| Ivory |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| Plastic |

|

| 240 | ||

|

|

|

|

|

|

|

|

|

FIGURE 11

TYPE | VERY FINE | FINE | MEDIUM | COARSE | VERY | |

COARSE | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

Aluminum Oxide | ||||||

|

|

|

|

|

|

FIGURE 12

9