CHECK TIRE PRESSURES

Service Interval: Every 25 Hours

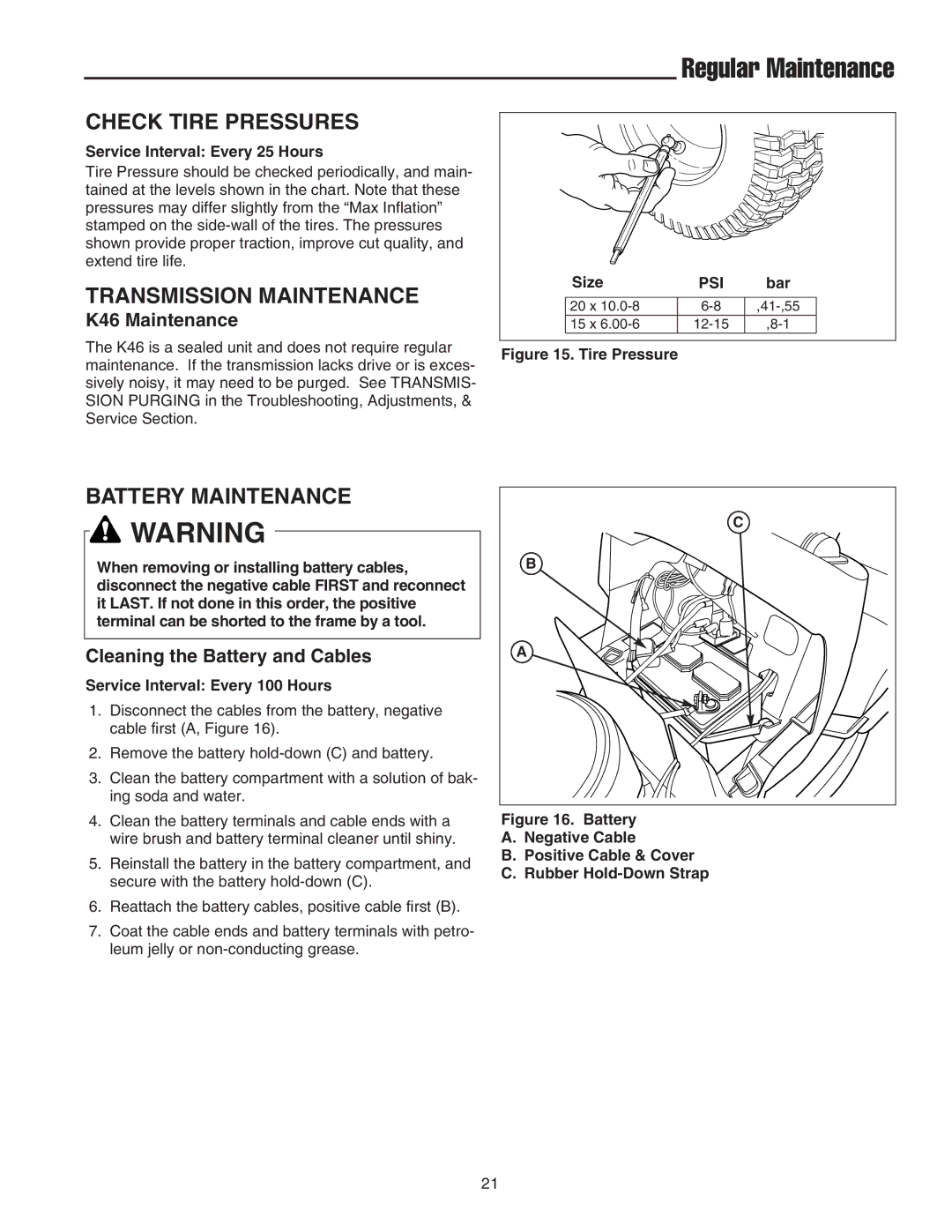

Tire Pressure should be checked periodically, and main- tained at the levels shown in the chart. Note that these pressures may differ slightly from the “Max Inflation” stamped on the

TRANSMISSION MAINTENANCE

K46 Maintenance

The K46 is a sealed unit and does not require regular maintenance. If the transmission lacks drive or is exces- sively noisy, it may need to be purged. See TRANSMIS- SION PURGING in the Troubleshooting, Adjustments, & Service Section.

Regular Maintenance

| Size |

|

|

|

|

|

| PSI | bar |

|

| ||

|

|

|

|

|

|

|

| 20 x |

|

|

| ||

| 15 x |

|

|

| ||

|

|

|

|

|

|

|

Figure 15. Tire Pressure

BATTERY MAINTENANCE

![]() WARNING

WARNING

When removing or installing battery cables, disconnect the negative cable FIRST and reconnect it LAST. If not done in this order, the positive terminal can be shorted to the frame by a tool.

Cleaning the Battery and Cables

Service Interval: Every 100 Hours

1.Disconnect the cables from the battery, negative cable first (A, Figure 16).

2.Remove the battery

3.Clean the battery compartment with a solution of bak- ing soda and water.

4.Clean the battery terminals and cable ends with a wire brush and battery terminal cleaner until shiny.

5.Reinstall the battery in the battery compartment, and secure with the battery

6.Reattach the battery cables, positive cable first (B).

7.Coat the cable ends and battery terminals with petro- leum jelly or

C |

B |

A |

Figure 16. Battery

A.Negative Cable

B.Positive Cable & Cover

C.Rubber Hold-Down Strap

21