Independent side leaves |

| |

allow the blade guard to |

| |

follow the stock being |

| |

cut closely and leave one |

| |

side flat on the table |

| |

when making narrow | The | |

cuts. This increases | ||

up out of the way individually or together. The entire guard system is modular (right) and | ||

safety and enhances dust | can be removed or reconfigured in seconds for changing blades or other operations. |

collection by keeping more of the blade area enclosed. Both side leaves can be rotated up out of the way independently to make measuring cut widths easy and more accurate. The entire side leaf assembly can be removed from the splitter by depressing a button at the hinge point to

increase access for blade changes without having to remove the splitter assembly.

The splitter plate is mounted

directly to the arbor housing so that the gap between it and the blade remains constant through height and bevel settings.

When necessary for procedures like cutting dados, the splitter assembly can be removed by simply flipping its locking lever within the throat opening and lifting it out.

Because the splitter is mounted directly to the blade mechanism, the gap between it and the blade never changes during height or angle adjustments. This maintains the safety a splitter affords in virtually all cutting situations.

Accu-Fence

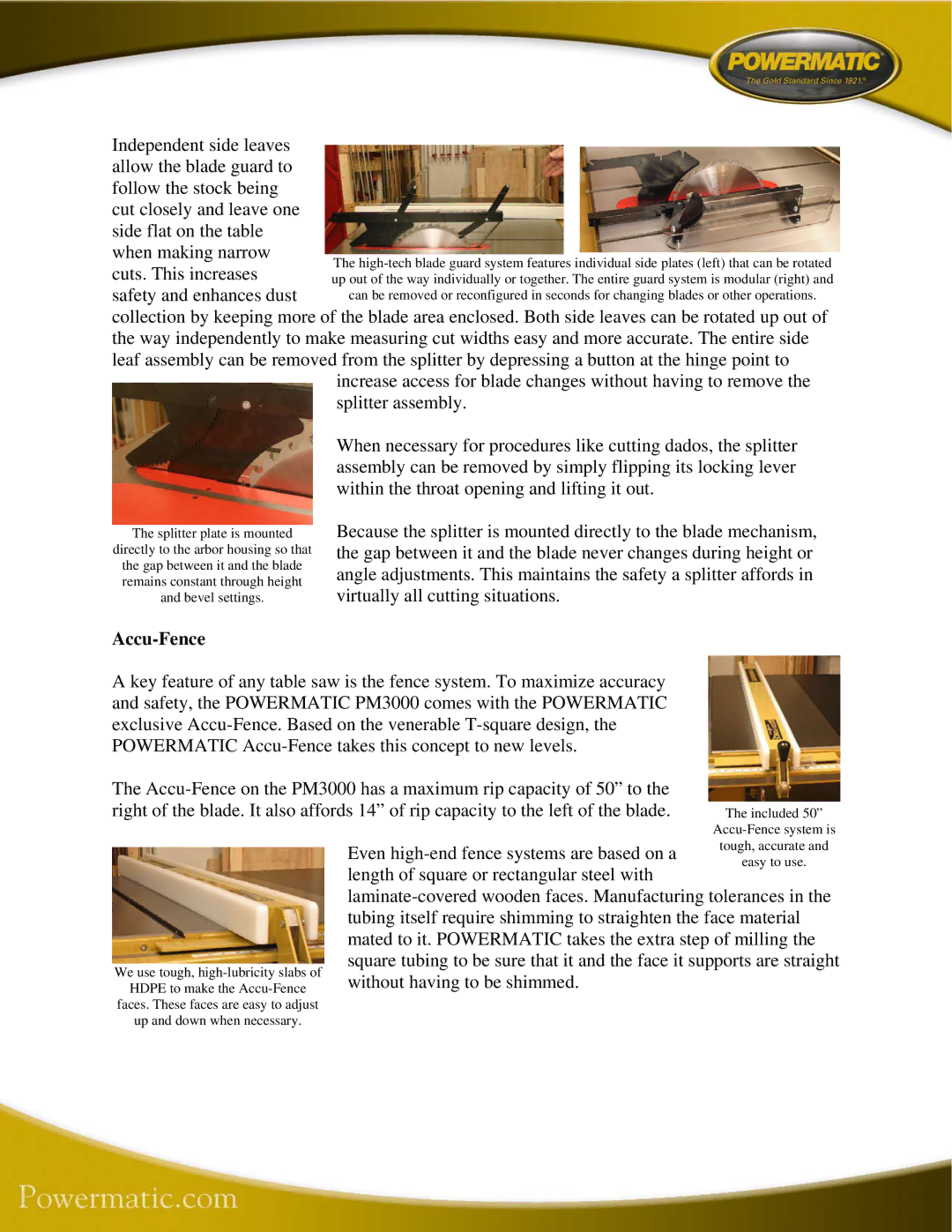

A key feature of any table saw is the fence system. To maximize accuracy and safety, the POWERMATIC PM3000 comes with the POWERMATIC exclusive

The

We use tough,

HDPE to make the

faces. These faces are easy to adjust

up and down when necessary.

Even