A perforated insert surrounds the blade with dust collection ports.

To help capture dust from above the table we developed a special insert plate with a grid of through holes. This creates a vacuum source surrounding the blade at the table surface to catch much of the dust other bandsaws leave on the surface.

We also added a dust brush that helps keep the lower drive wheel tire clean. This simple device limits the amount of dust that transfers on the blade to the upper wheel tire and cabinet. The result is cleaner,

To help keep the cut line clearly visible we added an integral air pump that supplies pressurized air to a nozzle attached to the upper blade guide. The air nozzle can be adjusted to keep dust from obscuring cut lines to allow you to work more accurately with fewer stops.

Power and Drive

The POWERMATIC

The motor power is delivered through a set of

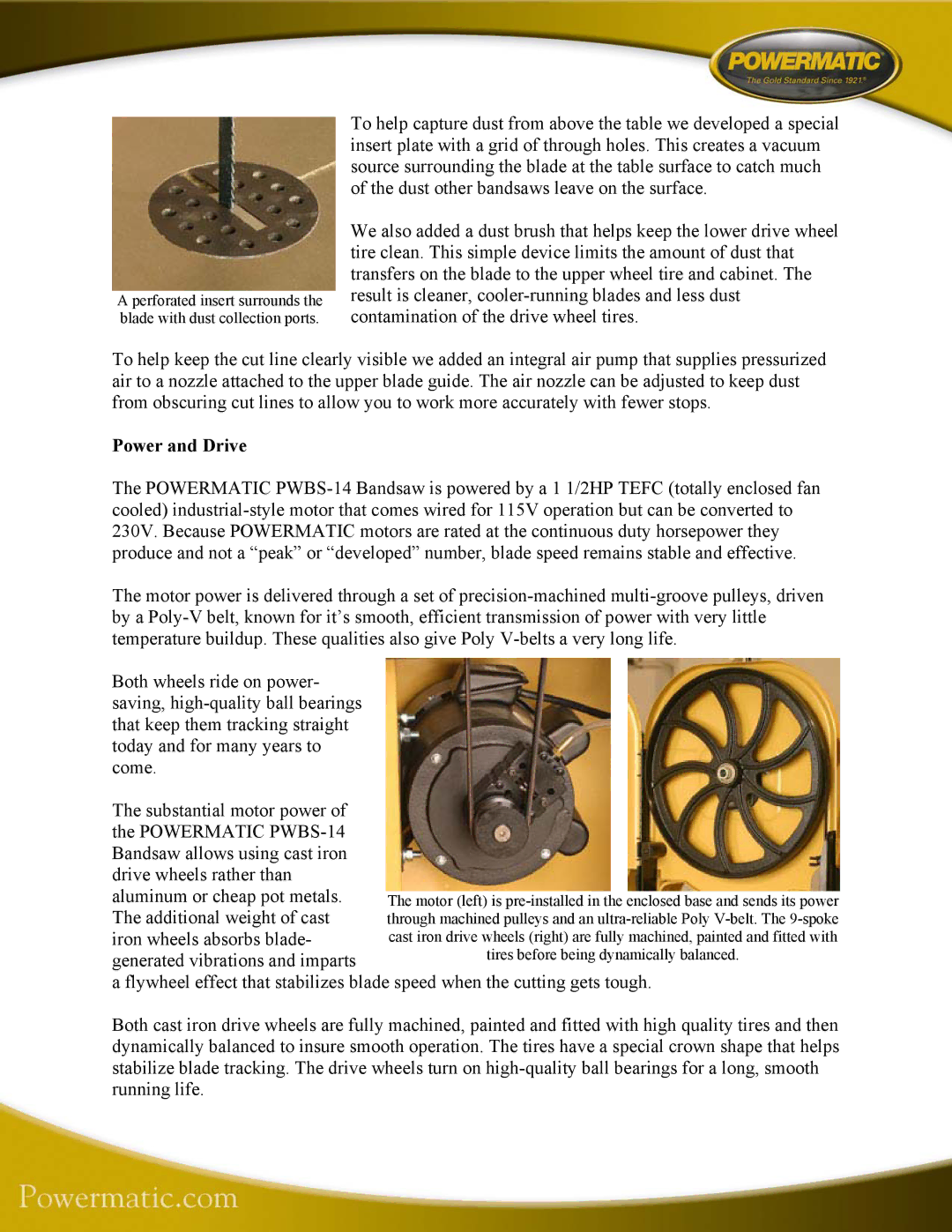

Both wheels ride on power- saving,

The substantial motor power of the POWERMATIC

a flywheel effect that stabilizes blade speed when the cutting gets tough.

Both cast iron drive wheels are fully machined, painted and fitted with high quality tires and then dynamically balanced to insure smooth operation. The tires have a special crown shape that helps stabilize blade tracking. The drive wheels turn on